1. Introduction

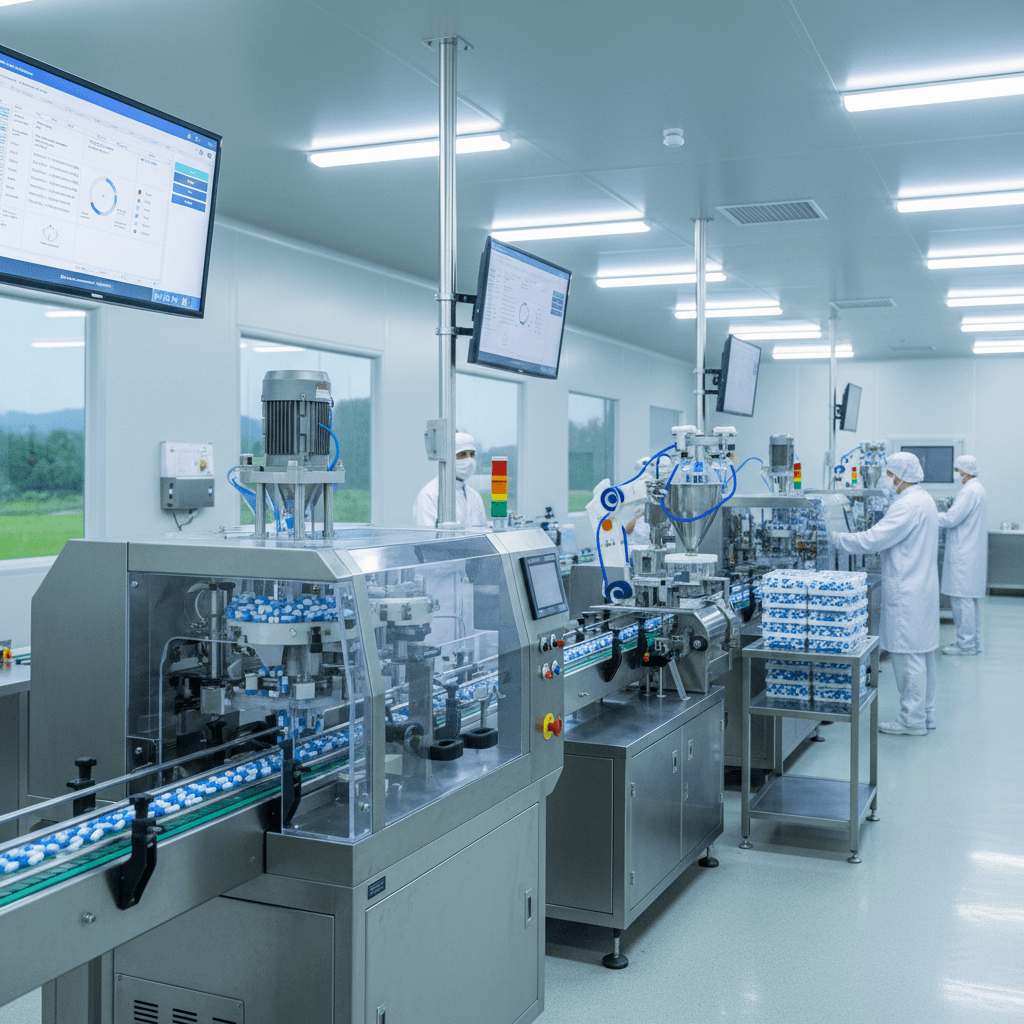

Capsule filling machines are a critical component in both pharmaceutical and nutraceutical manufacturing. In 2024, demand for high-quality capsule fillers continues to rise due to the growing health supplement and medication markets. Whether you need an automatic capsule filling machine for large-scale production or a manual capsule filler for laboratory use, understanding the equipment’s capabilities is essential.

2. What is a Capsule Filling Machine?

A capsule filling machine is designed to fill empty capsules (hard gelatin or HPMC) with powders, granules, or pellets. These machines improve production efficiency, ensure consistent dosing, and meet GMP pharmaceutical equipment standards.

Main types:

- Manual Capsule Fillers – Best for small batches and R&D.

- Semi-Automatic Capsule Filling Machines – Suitable for medium production runs.

- Automatic Capsule Filling Machines – High-speed systems for industrial operations.

3. Working Principle

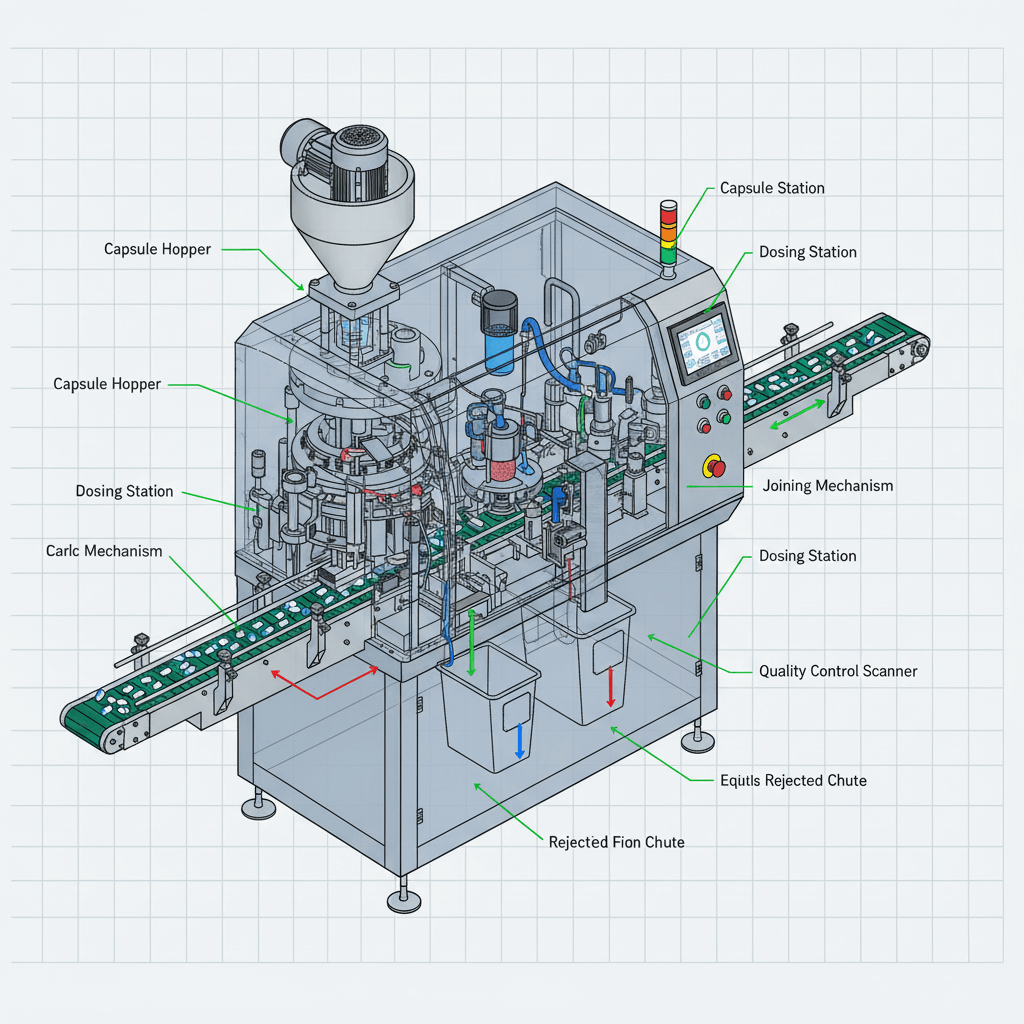

Automatic capsule filling machines operate in these steps:

- Capsule Orientation – Aligns caps and bodies.

- Filling – Powder or pellets are dosed into the body.

- Closing – Caps are rejoined with bodies.

- Ejection – Finished capsules exit the machine.

Advanced models feature vacuum positioning, real-time monitoring, and dose adjustment for consistent quality.

4. Capsule Filling Machine Selection Table

| Equipment Type | Output Capacity (Capsules/hour) | Capsule Sizes Supported | Price Range (USD) | Suitable For |

|---|---|---|---|---|

| Manual Capsule Filler | 500–3,000 | 0–5 | 300–300–2,000 | Labs, small batches |

| Semi-Automatic Capsule Filling Machine | 10,000–25,000 | 000–5 | 5,000–5,000–15,000 | Mid-sized production |

| Automatic Capsule Filling Machine | 25,000–200,000+ | 000–5 | 25,000–25,000–150,000 | Large-scale industrial production |

5. Key Features to Consider Before Buying

- Production capacity – Align with sales targets.

- Capsule size compatibility – Check the size range.

- Filling accuracy – Crucial for dosage compliance.

- Ease of cleaning – Prevent contamination.

- GMP compliance – Meet regulatory standards in your country.

6. Industry Insights

Based on years of experience in capsule production:

- Test powder flowability before full production runs.

- Implement dust extraction systems.

- Keep spare parts ready to reduce downtime.

- Regular calibration prevents regulatory violations.

7. Price Range

- Manual: 300–300 – 2,000

- Semi-Automatic: 5,000–5,000 – 15,000

- Automatic: 25,000–25,000 – 150,000

8. Maintenance Tips

- Preventive maintenance monthly.

- Lubricate moving parts with food-grade lubricants.

- Replace worn dosing components.

- Maintain full service records.

9. FAQ

Q1: Can one machine fill different capsule sizes?

Yes, if it supports multiple changeable dosing systems.

Q2: Which is better: imported or local machines?

Imported may offer higher precision, local provides quicker service.

Q3: How to increase accuracy?

Optimize powder particle size, control humidity, calibrate regularly.