In today’s manufacturing environment, selecting the right small packaging machine can significantly boost efficiency for both startups and established brands. Whether you’re looking for compact packaging equipment for food, cosmetics, or electronics, the right choice can save costs, optimize space, and ensure consistent quality. This guide will explain how a packaging machine for small business operates, the various types available, and expert tips for making the best purchase decision.

1. What is a Small Packaging Machine?

A small packaging machine is compact packaging equipment designed for modest production capacity. It’s perfect for small-scale manufacturing or startups looking to pack products efficiently. Despite its small footprint compared to industrial packaging lines, it can handle essential operations such as sealing, filling, labeling, weighing, and wrapping.

- Compact size – occupies minimal workspace.

- Easy to operate – minimal training required.

- Lower cost – affordable for growing SMEs.

- Flexibility – adapts to multiple packaging materials.

- Simple maintenance – cost-effective upkeep.

2. Working Principle of Small Packaging Machines

Small packaging machines operate using mechanical, pneumatic, or electronic systems depending on the model type. The working principles vary:

Filling Machines

Dispense precise quantities into containers using sensors or mechanical valves until preset volume or weight is achieved.

Sealing Machines

Apply heat, pressure, or adhesives to bond packaging material, protecting product integrity.

Wrapping Machines

Wrap products in films or plastic, commonly for bulk goods or retail-ready packs.

Labeling Machines

Apply adhesive labels automatically to product surfaces for branding and compliance.

3. Types of Small Packaging Machines

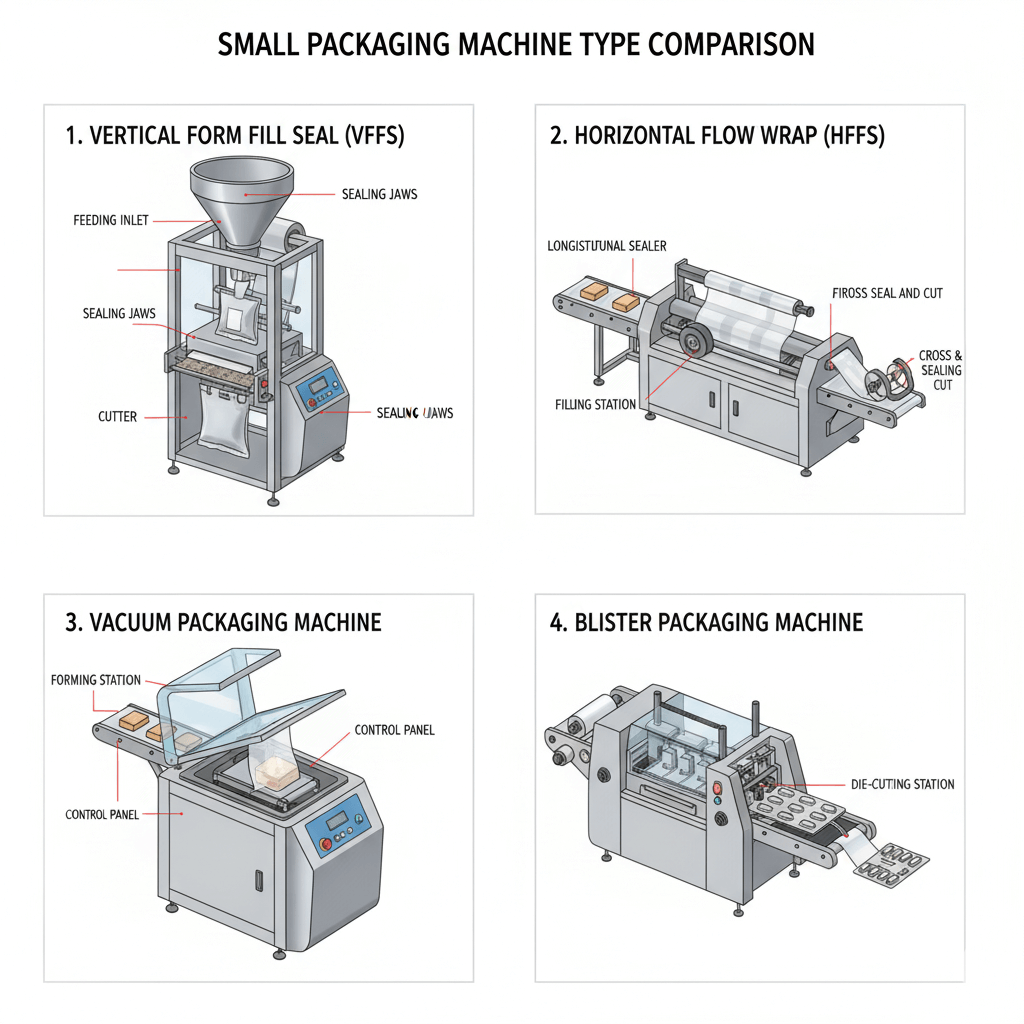

By Packaging Method

- Vertical Form-Fill-Seal (VFFS) Machines – ideal for granular and powdered products like coffee or sugar.

- Horizontal Flow Wrapper Machines – perfect for confectionery, baked goods, or medical items.

- Vacuum Packaging Machines – extend shelf life by removing air.

- Blister Packaging Machines – for tablets, capsules, hardware.

By Product Type

- Liquid filling machines.

- Powder filling machines.

- Granule filling machines.

By Automation Level

- Manual machines.

- Semi-automatic machines.

- Fully automatic machines.

4. Applications of Small Packaging Machines

They are widely used across industries:

- Food packaging machine – coffee, snacks, spices.

- Pharmaceuticals – tablets, capsules.

- Cosmetic packaging machine – cream, lotion.

- Cleaning products – detergent powder.

- Hardware – screws, bolts.

5. Advantages

- Cost efficiency.

- Space saving.

- Adaptability.

- Quick setup.

- Reduced waste.

6. How to Choose the Right Small Packaging Machine

- Match to product type.

- Consider speed requirements.

- Check material compatibility.

- Review budget and ROI.

- Evaluate supplier reputation.

7. Maintenance Tips

- Clean regularly.

- Lubricate moving parts.

- Inspect electrical components.

- Replace worn parts promptly.

- Follow manufacturer guidelines.

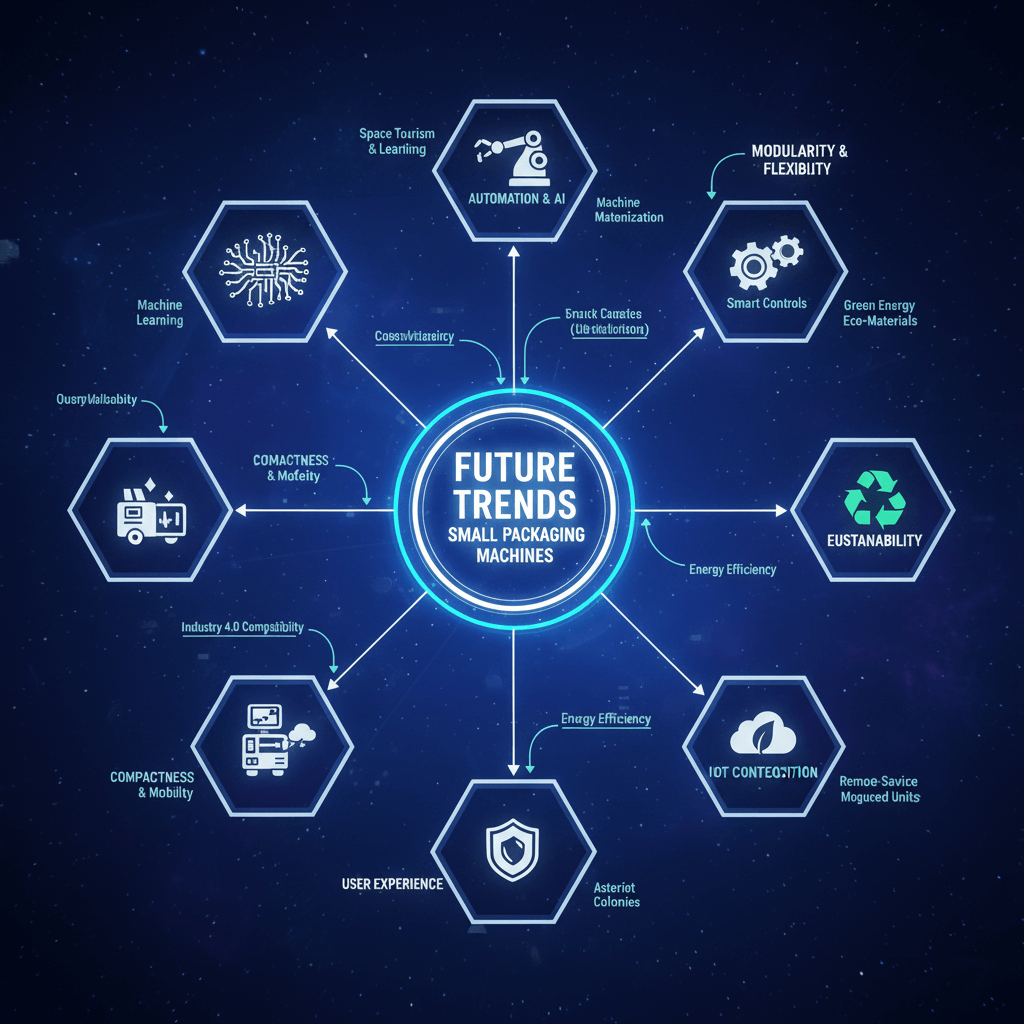

8. Future Trends

- IoT-enabled monitoring.

- Eco-friendly materials.

- Modular design.

- AI-assisted packaging.