Einführung

In the nutraceutical, pharmaceutical, and contract manufacturing sectors, fully automatic capsule filling machines have become the backbone of efficient, compliant capsule production. This guide explains what these machines are called, how they work, the typical price range, hourly output, training requirements, relevant regulations, and how to choose the right model. We also compare automatic, semi-automatic, and manual capsule fillers to help you plan your capsule filling line for current and future demand.

What Is a Capsule Filling Machine Called?

A capsule filling machine is commonly referred to as a “capsule filler,” “capsule filling machine,” or “encapsulation machine.” In industrial settings, “fully automatic capsule filling machine” typically means a system that automates capsule feeding, orientation, separation, powder or pellet dosing, tamping, closing, and ejection—often integrated with an automatic capsule loader.

How Does an Automatic Capsule Filling Machine Work?

Automatic capsule fillers streamline the entire encapsulation process through synchronized stations. While designs vary by manufacturer, a typical workflow includes:

– Capsule loading and orientation: Empty capsules are fed via an automatic capsule loader, oriented with caps and bodies facing the correct direction.

– Separation: The machine gently separates the cap from the body under vacuum or mechanical action.

– Dosing: The formulation—powder, granules, pellets, or micro-tablets—is metered into the capsule body using dosing discs, tamping pins, augers, or vacuum dosing systems for accurate fill weights.

– Compacting: Tamping pins compress powder layers to achieve target density and consistent mass.

– Optional features: Multi-station dosing for combination fills, pellet dosing, liquid filling (on specialized models), and in-line weight checking.

– Closing: The cap is rejoined with the body and locked.

– Ejection and rejection: Filled capsules are discharged; any off-spec units are auto-rejected for quality assurance.

How Many Capsules Can an Automatic Machine Fill per Hour?

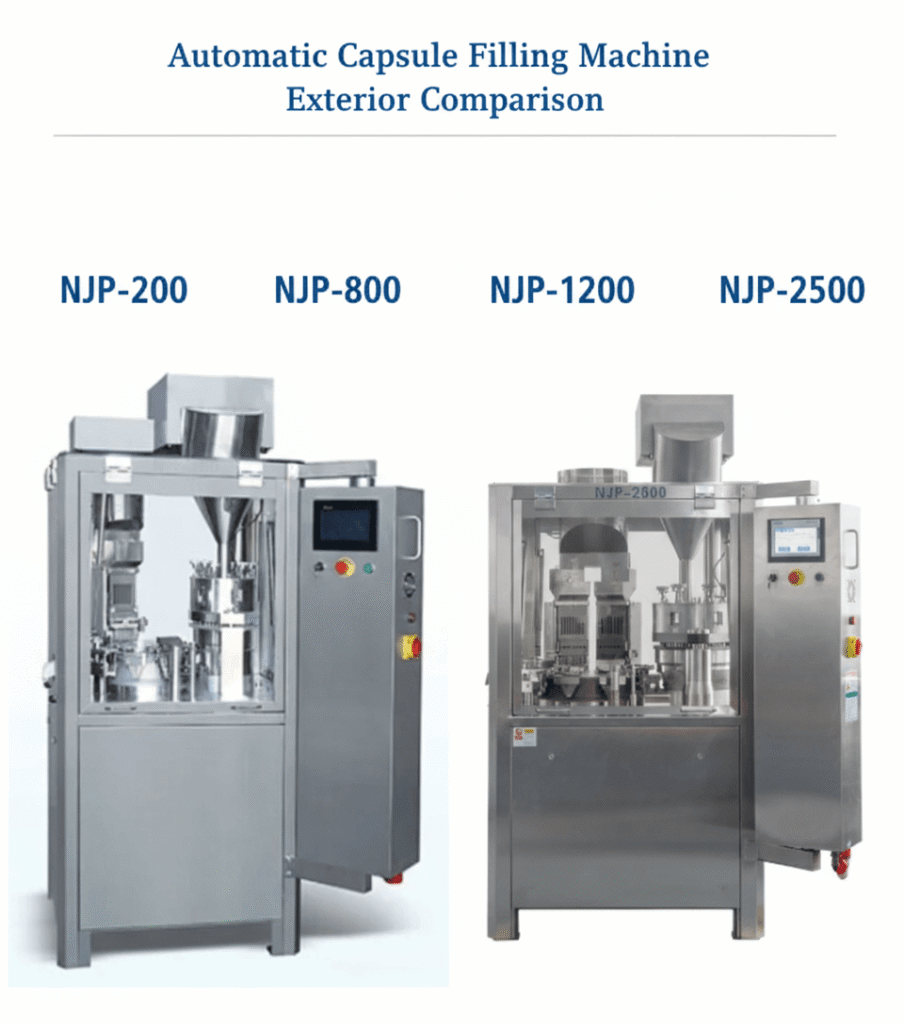

Capacity depends on model, number of holes/stations, and formulation characteristics. Typical ranges:

– Entry-level automatic: 30,000–60,000 capsules/hour

– Mid-range: 80,000–120,000 capsules/hour

– High-speed: 150,000–250,000+ capsules/hour

Note: Real throughput varies based on capsule size (e.g., 00, 0, 1–4), powder flowability, and quality control settings (e.g., weight checking and rejection rates).

How Much Does a Capsule Machine Cost?

Pricing varies by automation level, capacity, build quality, and compliance options:

– Manual capsule filler: USD 200–1,500 (small-batch, lab or artisan use)

– Semi-automatic capsule filler: USD 8,000–35,000 (good for SMEs ramping up)

– Fully automatic capsule filling machine: USD 45,000–250,000+ (industrial scale)

– Capsule filling line (loader + filler + polishing + metal detector + sorting): USD 80,000–450,000+, depending on speed and integration

For a precise automatic capsule filling machine price, consider whether you need an automatic capsule loader, in-line weight checking, dust extraction, pellet dosing, or 21 CFR Part 11 data logging.

How to Fill Capsules: Manual vs. Semi-Automatic vs. Fully Automatic

– Manual capsule filler: Operators place empty capsules, separate by hand, spread the powder, level/tamp manually, and lock the caps. Suitable for R&D or small batches; slow and labor-intensive.

– Semi-automatic capsule filler: Machines separate and fill capsules, but operators still perform certain steps like loading capsules and powders, and assisting with locking/ejection. Faster than manual yet requires active supervision.

– Fully automatic capsule filling machine: Continuous, hands-off operation with automated feeding, dosing, closing, and ejection. Ideal for consistent, high-speed production on a capsule filling line.

Do Capsule Fillers Require Special Training?

Yes, but it’s manageable. Operators should be trained on:

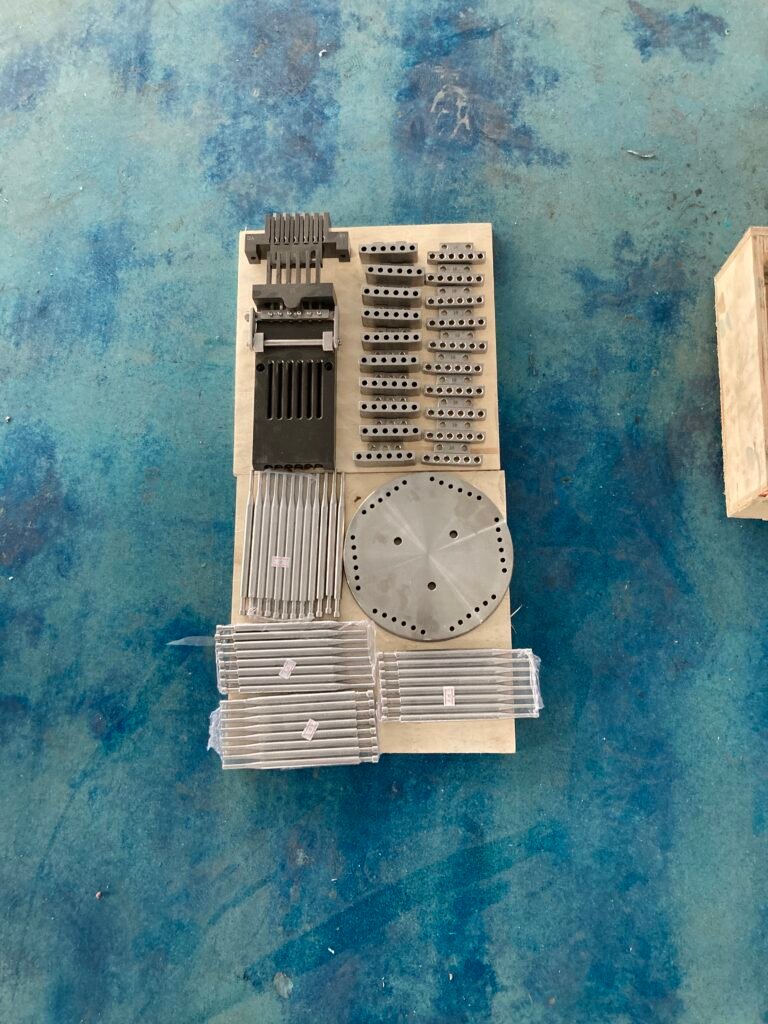

– Machine setup and changeover (e.g., switching capsule sizes)

– Dosing calibration and in-process weight control

– Cleaning and sanitation for cross-contamination prevention

– Troubleshooting powder flow, vacuum settings, and capsule quality

– Safety protocols (moving parts, electrical systems, PPE)

Many suppliers offer commissioning and training packages. A structured SOP and preventive maintenance plan help sustain yield and compliance.

Are Capsule Filling Machines Regulated?

Regulations focus on manufacturing environment, documentation, and product quality rather than the machine alone. Depending on your market:

– GMP: Good Manufacturing Practice (cGMP in the US, EU GMP) governs facility, equipment qualification (IQ/OQ/PQ), cleaning validation, and batch records.

– FDA 21 CFR Part 211: US regulations for finished pharmaceuticals; 21 CFR Part 11 covers electronic records.

– ISO 9001/13485: Quality management and medical device contexts.

– CE marking/UL: Equipment safety standards for certain markets.

For nutraceuticals and supplements, local rules vary; compliance with GMP and quality control (e.g., weight variation, disintegration if applicable) remains critical.

What Are the Disadvantages of Manual Capsule Filling Machines?

– Low throughput: Not viable for commercial scale.

– Inconsistent dosing: Greater risk of weight variation and quality issues.

– Labor-intensive: Higher operating costs per unit.

– Limited compliance: Harder to meet stringent GMP documentation and validation.

– Higher contamination risk: More manual touch points.

How Do I Choose the Right Machine?

Use these criteria to match your needs:

– Throughput requirement: Define hourly and monthly capacity targets; plan 20–30% buffer for growth.

– Formulation type: Powders vs. pellets; consider flowability, hygroscopicity, and required tamping density.

– Capsule sizes and materials: Gelatin vs. HPMC/plant-based; ensure compatibility with your sizes (00–4).

– Accuracy and QA: Look for in-line weight checking, metal detection, and auto-reject to minimize variability.

– Integration: Decide if you need an automatic capsule loader, polishing, sorting, and packaging connectivity.

– Compliance and data: 21 CFR Part 11-ready HMI, batch reporting, IQ/OQ/PQ support.

– Footprint and utilities: Space, power, compressed air, dust extraction.

– Service and spares: Local support, lead times for change parts, and training availability.

– Budget and ROI: Balance CAPEX vs. throughput, yield, and labor savings. Consider a semi automatic capsule filler if ramping up from manual production.

Automatic Capsule Filling Machine for Sale: What to Look For

– Construction quality: Stainless steel contact parts, GMP-compliant design, tool-less change parts.

– Dosing system versatility: Swappable modules for powders, pellets, or micro-tablets.

– Stability: Low vibration, precise indexing for consistent fill weights.

– Safety: Interlocks, emergency stops, and guarded enclosures.

– Documentation: Validation support, manuals, and spare parts catalog.

– Trials: Request sample runs for your formulation to verify fill accuracy and capsule integrity.

Building a Scalable Capsule Filling Line

For reliable scale-up, align upstream and downstream:

– Upstream: Automatic capsule loader, dehumidification for sensitive powders, consistent raw material flow.

– Core: Fully automatic capsule filling machine sized to your throughput.

– Downstream: Capsule polishing, sorting, metal detection, visual inspection, and packaging.

– Data and QA: In-line weight check and batch reporting for traceability.

Schlussfolgerung

Choosing the right capsule filling solution depends on your capacity, formulation, compliance, and ROI targets. For commercial-scale operations, a fully automatic capsule filling machine—paired with an automatic capsule loader and downstream QA—delivers the throughput, consistency, and regulatory readiness that modern markets demand. If you’re transitioning from manual to automated production, a semi automatic capsule filler can be a cost-effective bridge while you validate processes and scale volumes.

Need personalized recommendations or a quotation? Contact us to discuss your product, capacity goals, and compliance requirements. We’ll help you configure an optimal capsule filling line and provide sample runs to validate performance before purchase.