Architecture, Control Logic, and Engineering Advantages

In high‑speed automatic packaging machines, film position stability is a decisive factor affecting sealing accuracy, printed pattern registration, and overall packaging quality.

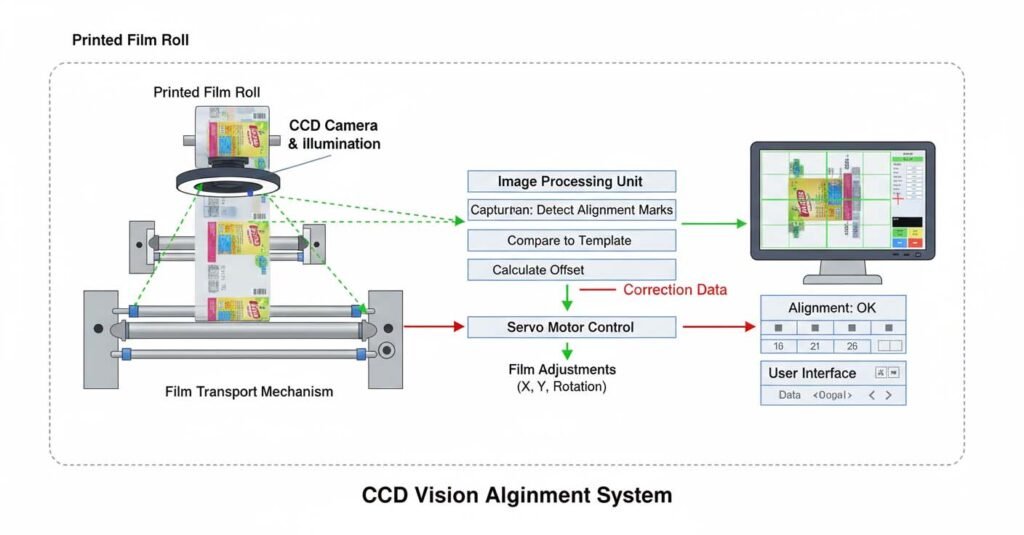

A CCD vision‑based film alignment system has become a standard solution in modern packaging equipment, replacing traditional mechanical deviation correction methods through real‑time image processing and closed‑loop servo control.

Dieser Artikel enthält eine technical deep dive into the system architecture, working principles, control logic, and engineering value of CCD vision film alignment systems.

1. Film Deviation Phenomenon in Continuous Packaging Processes

During continuous film feeding, deviation occurs when the film’s actual running position differs from its theoretical centerline.

Common sources of deviation include:

• uneven unwinding tension from film rolls

• asymmetric friction on guide rollers

• inconsistent film thickness or stiffness

• inertia effects during acceleration and deceleration

• long‑term cumulative drift in high‑speed operation

Even minimal deviation (1–2 mm) can result in significant sealing misalignment and printed pattern displacement.

2. Limitations of Traditional Mechanical Alignment Systems

Mechanical correction systems typically use edge sensors, guide rollers, or passive steering mechanisms.

Inherent limitations:

• open‑loop or semi‑closed control

• slow dynamic response

• limited resolution

• poor adaptability to printed film

As packaging speeds increase and pouch structures become more complex, mechanical systems fail to meet modern accuracy requirements.

3. System Architecture of a CCD Vision Film Alignment System

A CCD vision alignment system is composed of optical sensing, digital processing, and motion execution modules, forming a fully closed‑loop control architecture.

Core subsystems include:

- Optical image acquisition

- Image processing and deviation calculation

- Control algorithm and motion command generation

- Servo‑driven correction mechanism

Each subsystem operates continuously and synchronously with the packaging process.

4. Optical Image Acquisition and Detection Strategy

The CCD camera captures high‑resolution images of the moving film.

Detection methods typically include:

• registration mark recognition

• edge contour detection

• contrast‑based pattern tracking

A dedicated lighting system ensures consistent illumination regardless of film material, reflectivity, or printing color.

5. Image Processing and Deviation Calculation

Captured images are analyzed in real time using digital image processing algorithms.

Typical processing steps:

- Image preprocessing (noise filtering, contrast enhancement)

- Feature extraction (mark centroid or edge coordinates)

- Deviation measurement relative to reference position

- Signal output to motion controller

Deviation data is converted into quantified positional error for correction.

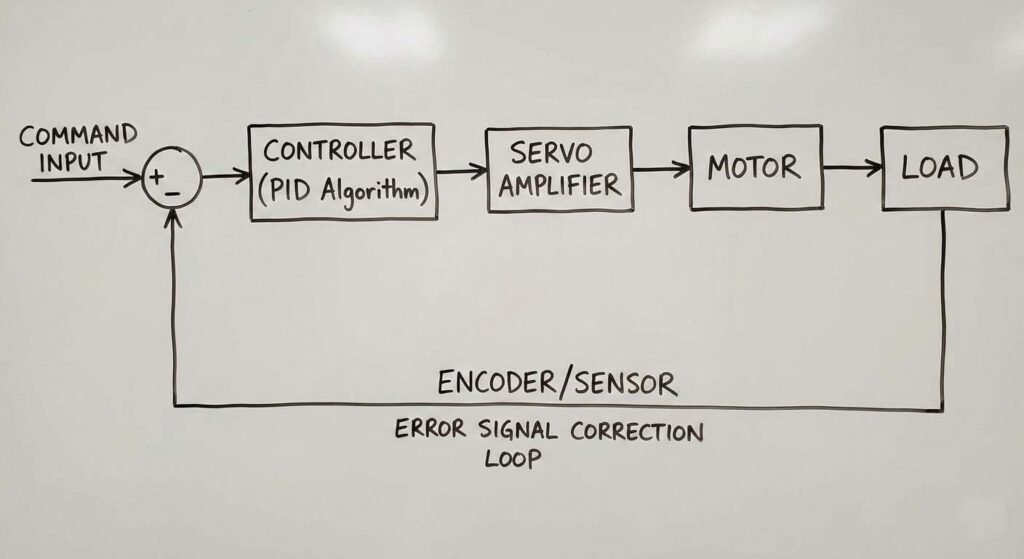

6. Closed‑Loop Servo Correction Logic

At the core of the system is closed‑loop servo control.

Control flow:

• deviation signal → control algorithm → servo command

• servo actuator adjusts film guide or correction roller

• new position is re‑measured by CCD camera

This continuous feedback loop enables dynamic, high‑precision correction.

Engineering benefits:

✅ high positional resolution

✅ rapid response to disturbance

✅ stable performance at variable speeds

7. Integration with Packaging Machine Motion System

The CCD vision alignment system operates in coordination with:

• film feeding servo

• sealing position servo

• cutting or punching modules

Synchronization ensures alignment correction does not introduce secondary disturbances in downstream processes.

8. Impact on Sealing Accuracy and Pouch Geometry

Accurate film alignment directly influences:

• top and side seal symmetry

• bottom forming consistency

• pouch dimensional stability

This is particularly critical for stand‑up pouches (doypack), where bottom geometry affects standing performance.

9. Influence on Printed Pattern Registration

For printed film, even minor misalignment can cause:

❌ off‑center logos

❌ inconsistent color blocks

❌ brand appearance degradation

CCD vision alignment ensures repeatable pattern positioning, meeting high‑end branding requirements.

10. Material Utilization and Waste Reduction

Uncontrolled deviation leads to frequent scrap during startup and production.

CCD vision systems significantly reduce: ✅ initial setup waste

✅ continuous running scrap

✅ manual intervention

This contributes to lower operating costs and improved production efficiency.

11. Reliability, Maintenance, and System Stability

Compared to mechanical systems, CCD vision alignment offers:

• fewer mechanical wear parts

• reduced recalibration frequency

• stable long‑term accuracy

Maintenance focuses on:

• lens cleanliness

• lighting calibration

• software parameter verification

12. Advanced Trends in Vision‑Based Alignment Systems

Future developments include:

• higher frame‑rate cameras

• AI‑based image recognition

• adaptive control algorithms

• deep IIoT integration

These trends further enhance self‑learning and predictive correction capabilities.

13. Engineering Value Summary

From an engineering perspective, CCD vision‑based film alignment systems provide:

✅ superior positional accuracy

✅ enhanced packaging quality

✅ reduced material waste

✅ improved automation level

They represent a critical enabling technology for high‑speed, high‑precision packaging machines.

Schlussfolgerung

The CCD vision‑based film alignment system is no longer an optional upgrade but a core subsystem in modern packaging machinery.

By integrating optical sensing, digital image processing, and servo motion control, it delivers the precision and stability required by today’s packaging industry.