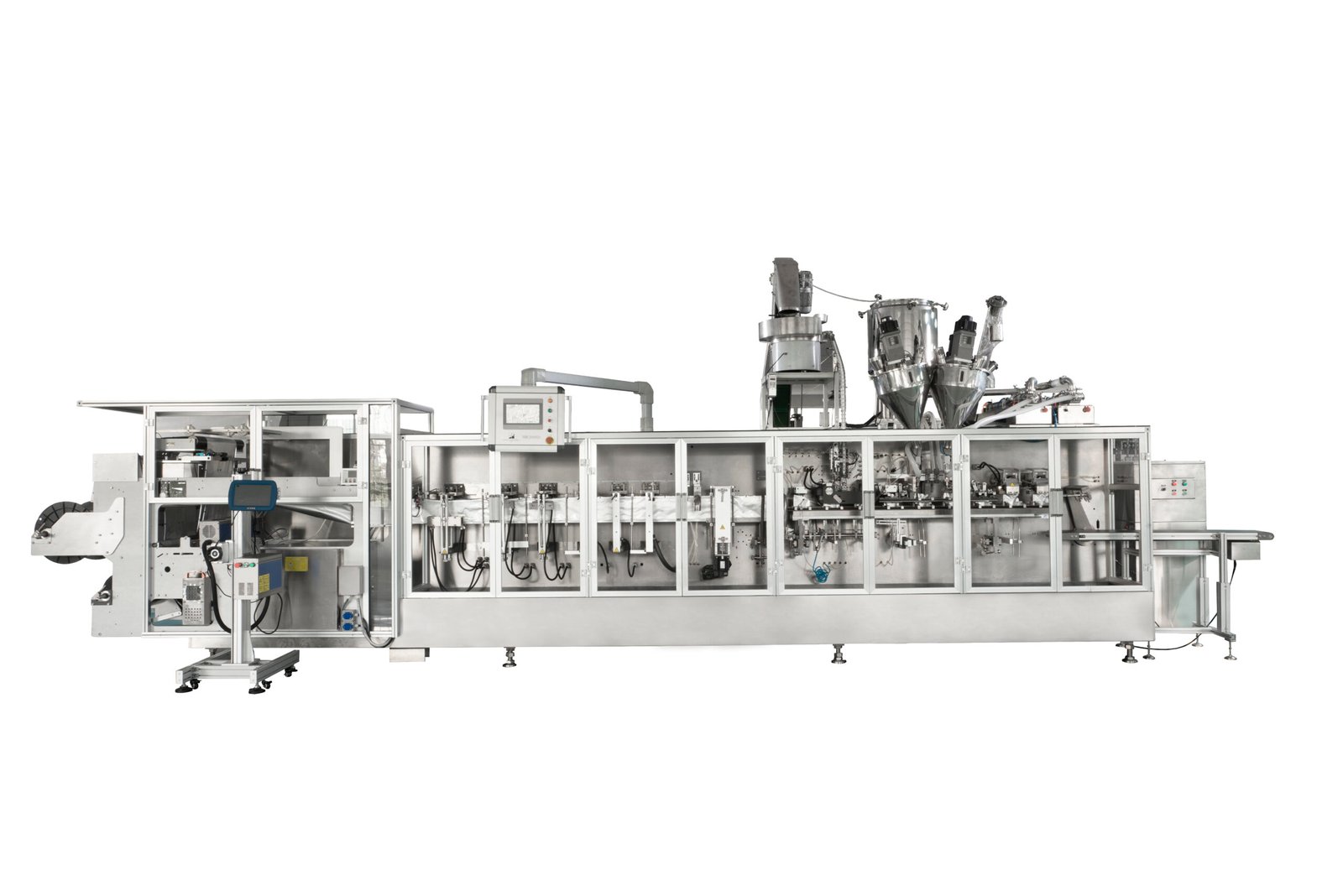

En HMK series doypack packaging machine is designed for high‑precision pouch forming, filling, and sealing, focusing on servo control, intelligent positioning, and production stability.

This article introduces the core technical features y model specifications of the HMK series from an engineering perspective.

Overview of HMK Series Packaging Machines

The HMK series is suitable for bolsas autoportantes (doypack) with various sizes and volumes.

It supports flexible production requirements while maintaining stable sealing quality and high operational efficiency.

The series covers multiple models, from compact machines for small pouches to high‑speed full‑servo systems for large‑scale production.

Key Technical Features of HMK Series

This section focuses on core mechanical and control technologies integrated into the HMK platform.

Automatic Bottom Punching Servo Positioning System for Doypack

The HMK series adopts a servo‑driven bottom punching positioning system, ensuring accurate and repeatable hole positioning for doypack forming.

✅ Improves bottom stability

✅ Enhances pouch appearance

✅ Reduces mechanical tolerance errors

CCD Vision Servo Film Deviation Correcting System

A CCD vision system combined with servo correction is used for automatic film alignment.

• Real‑time detection of film deviation

• Closed‑loop servo correction

• Reduced material waste

This system is especially important for printed film with registration marks.

Rapid Edge Sealing Specification Conversion Module

The HMK series includes a positioning module for fast conversion of edge sealing specifications.

✅ Shorter changeover time

✅ Reduced setup complexity

✅ Improved production flexibility

This is ideal for factories producing multiple pouch formats.

Servo Seal Position Adjustment (FE Model Optional)

For FE models, a servo seal position adjustment module allows precise control of bag length.

• No mechanical adjustment required

• High repeatability

• Suitable for frequent size changes

Servo Bag Width Adjustment Module (FE Model Optional)

Bag width adjustment in FE models is also servo‑controlled.

This design: ✅ Eliminates manual fine‑tuning

✅ Improves dimensional consistency

✅ Reduces operator dependency

Automatic Lubrication System

En automatic lubrication system is integrated to ensure smooth mechanical operation.

• Reduces wear of moving components

• Extends equipment service life

• Minimizes maintenance workload

Cooling Device for Strengthened Top Seal

A dedicated cooling device is used to stabilize the top sealing area.

This improves: ✅ Seal strength

✅ Pouch appearance

✅ Packaging reliability

Pouch Conveyor Module with Maglev Guideway

The pouch conveyor uses a maglev guideway structure, enabling:

• Smooth pouch transfer

• Reduced vibration

• Higher output stability at high speed

Production Management System (HMI) and IIoT Integration (Optional)

The HMK series can be equipped with a Production Management System (PMS) integrated with HMI and Industrial Internet of Things (IIoT).

Functions include: ✅ Online production monitoring

✅ Real‑time performance data

✅ Equipment status management

This option is suitable for smart factory environments.

Full Servo Configuration for FE Series

En FE series is available in a full servo version, providing:

• Higher precision

• Faster response

• Better synchronization

This configuration is recommended for high‑end packaging applications.

HMK Series Equipment Models and Technical Specifications

| Modelo | Mini Bag Size (mm) | Max Bag Size (mm) | Bag Volume | Speed (PPM) | Potencia |

|---|---|---|---|---|---|

| HMK160 | 70×120×20 | 180×250×45 | 1000 ml | 50 | 15 kW |

| HMK220 | 80×120×20 | 210×300×60 | 2000 ml | 50 | 15 kW |

| HMK260FE | 80×120×20 | 260×300×60 | 2500 ml | 40 | 28 kW |

| HMK320FE | 80×120×20 | 320×300×60 | 3000 ml | 40 | 28 kW |

| HMK420FED | 80×120×20 | 210×300×60 | 2000 ml | 100 | 30 kW |

| HMK420FEQ | 80×120×20 | 105×210×35 | 200 ml | 200 | 32 kW |

| HMK540Q | 135×150×30 | 135×300×45 | 750 ml | 200 | 35 kW |

Film size range:

Maximum film diameter 400 mm

Core diameter 76 mm or 152 mm

Typical Applications of HMK Series

HMK doypack machines are widely used in:

✅ food and snack packaging

✅ coffee and powder products

✅ liquid and paste filling

✅ daily chemical packaging

Stable forming and sealing quality make them suitable for export‑oriented packaging lines.

Engineering Advantages of HMK Series

From a technical standpoint, the HMK series offers:

• High positioning accuracy

• Reduced changeover time

• Stable high‑speed operation

• Modular and scalable configuration

These advantages help manufacturers maintain consistent output and long‑term operational reliability.

Conclusión

The HMK series doypack packaging machine integrates servo control, vision alignment, and intelligent production management into a single platform.

For factories seeking precision, flexibility, and scalability, HMK provides a technically mature solution for modern pouch packaging lines.