1. Introducción

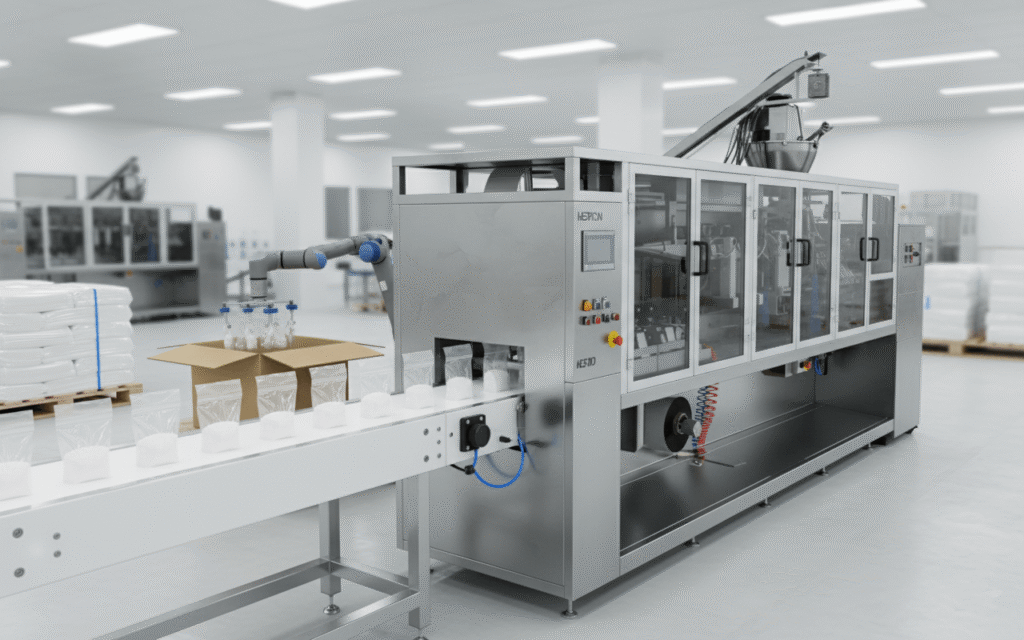

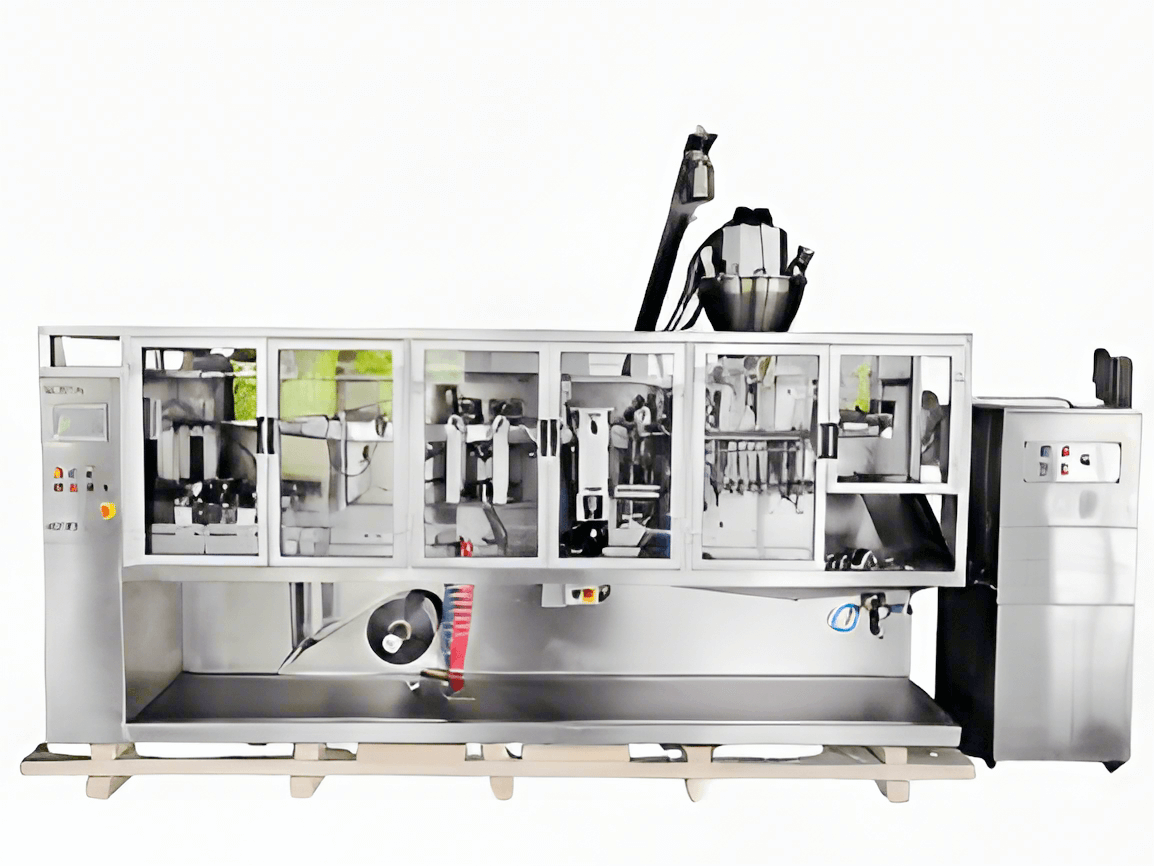

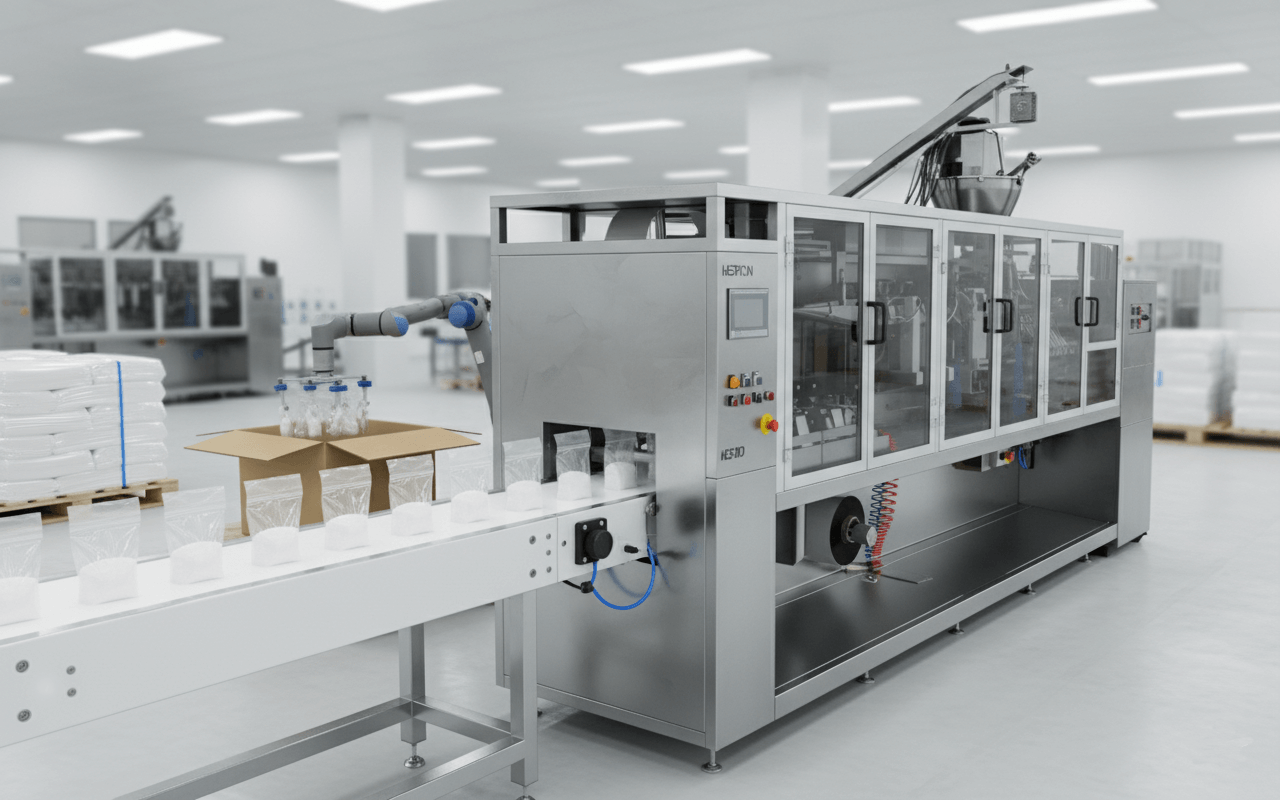

En HS-160D Packaging Machine is engineered for businesses seeking high-speed, precision packaging with professional quality. Its advanced automation and intelligent controls help reduce labor, improve efficiency, and deliver a consistent product every time.

2. How the HS-160D Works

The HS-160D operates through a streamlined flow:

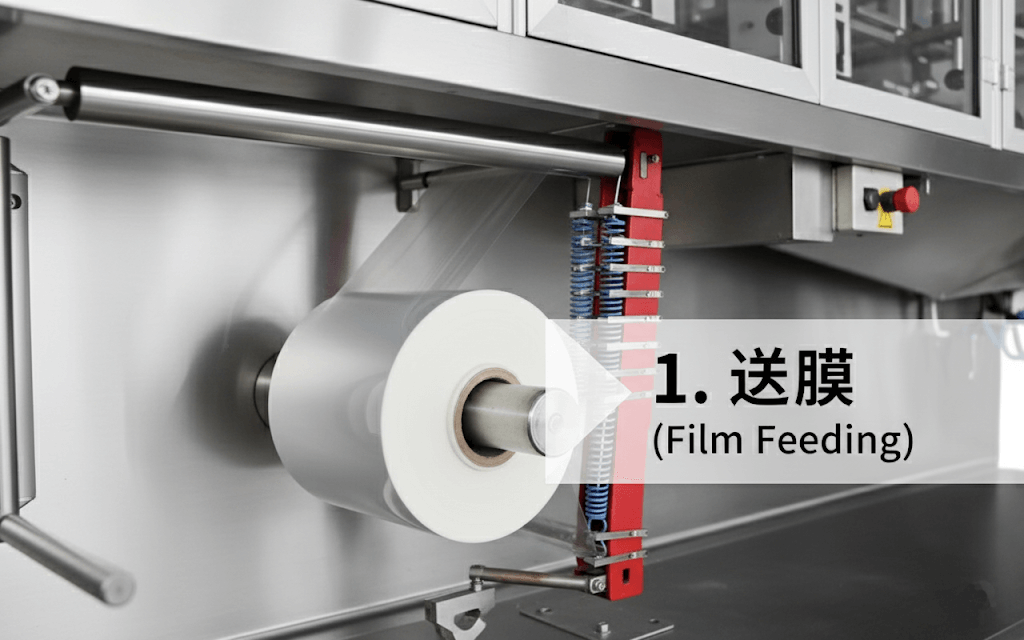

- Film Feeding – The machine automatically feeds the packaging film into position.

- Product Filling – Items are precisely loaded into the film.

- Sealing & Cutting – Heat sealing ensures strong seals, and cutting produces individual packages.

- Finished Product Output – Clean, professional packages are ready for distribution.

3. Key Features & Advantages

| Feature | Description |

|---|---|

| High-Speed Operation | Up to 160 packs per minute |

| Precision Sealing | Consistent quality to prevent leaks |

| Versatile Packaging Formats | Pillow packs, gusseted bags, and more |

| Touchscreen Control Panel | Easy setup and real-time monitoring |

| Compact Footprint | Saves valuable production space |

| Energy Efficiency | Optimized design lowers electricity costs |

Advantages

- Boosts productivity and reduces downtime

- Ensures product safety through strong seals

- Suitable for food, pharmaceuticals, and non-food goods

- Lower operational costs through automation

4. Technical Specifications

| Especificación | Valor |

|---|---|

| Velocidad de envasado | ≤160 packs/min |

| Film Width | 60–200 mm |

| Fuente de alimentación | AC 220V, 50/60 Hz |

| Dimensiones de la máquina | 2900 × 850 × 1450 mm |

| Peso | 500 kg |

5. Applications

The HS-160D Packaging Machine serves multiple industries:

- Snacks & confectionery

- Pharmaceuticals & medical supplies

- Frozen food packaging

- Household product wrapping

6. Why Choose HS-160D?

Choosing the HS-160D means investing in:

- Reliability – Built for continuous operation

- Flexibility – Adjustable settings for different products

- Future-Proof – Designed for modern automated production lines

7. Conclusión

En HS-160D Packaging Machine delivers speed, accuracy, and versatility. It’s ideal for businesses aiming to scale production without compromising on quality. By integrating this machine into your workflow, you can expect professional packaging results, reduced costs, and higher output.