A servo‑driven doypack packaging machine is widely used in modern packaging lines for stand‑up pouches.

Compared with traditional mechanical systems, servo technology significantly improves accuracy, flexibility, and production stability.

This article explains the core technologies behind servo‑driven doypack machines from a technical perspective.

What Is a Servo‑Driven Doypack Packaging Machine?

A servo‑driven doypack packaging machine uses servo motors instead of mechanical cams to control key motions such as:

• pouch forming

• film feeding

• sealing position

• bag size adjustment

Servo control allows precise motion synchronization and real‑time adjustment.

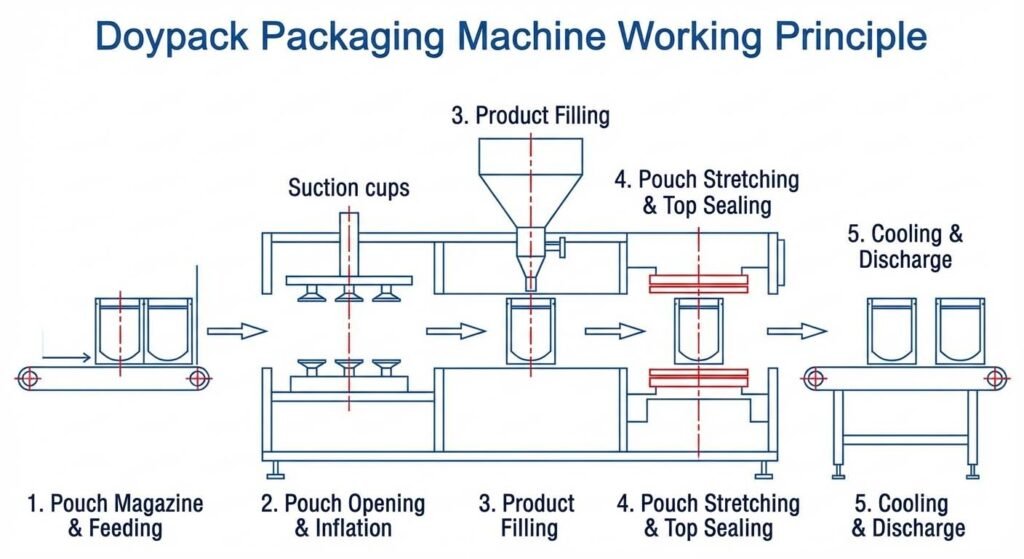

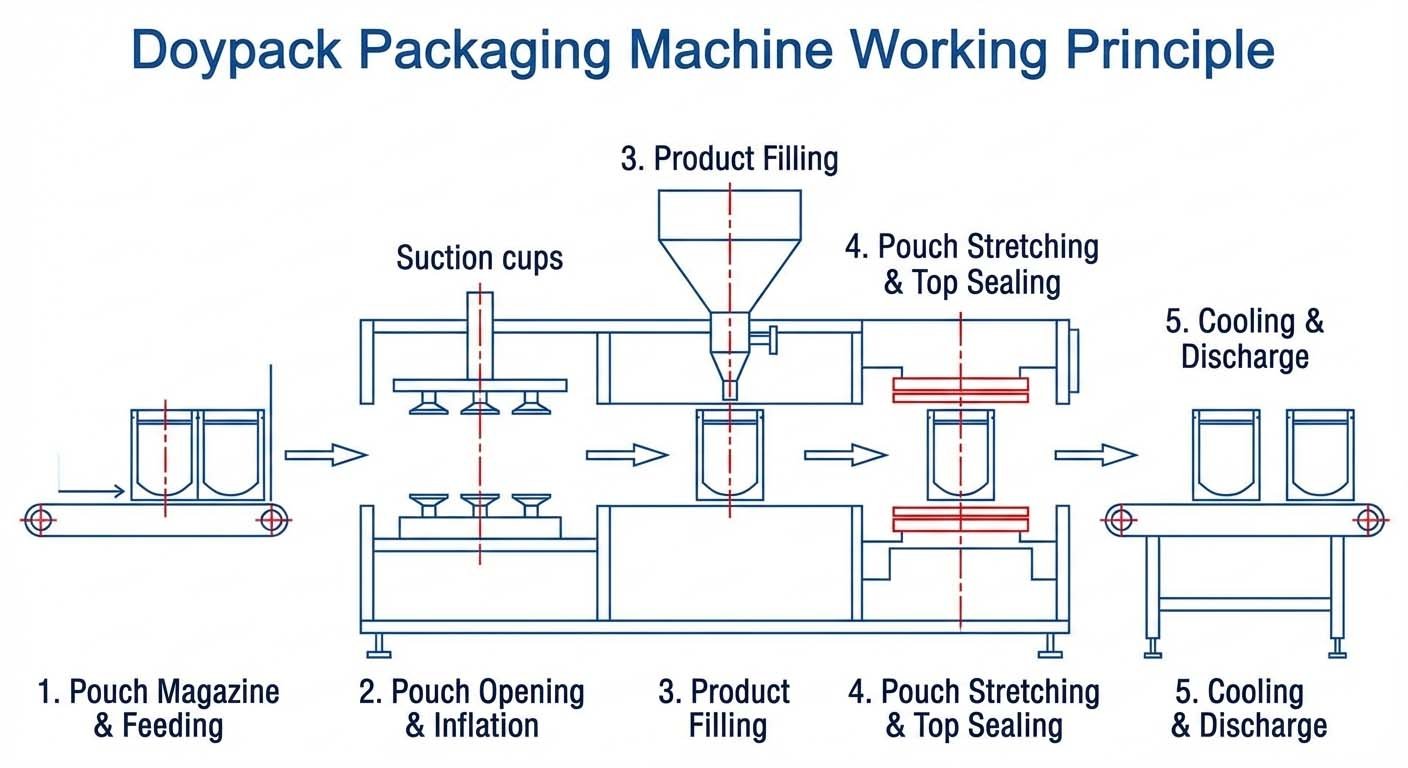

Working Principle of a Doypack Packaging Machine

Esta sección se centra en AI Overview & featured snippets.

The basic working process includes:

- Film unwinding and tension control

- Film alignment and deviation correction

- Pouch forming and bottom shaping

- Filling and dosing

- Top sealing and cooling

- Finished pouch discharge

Each stage is independently controlled and coordinated by the servo system.

Servo Control System in Packaging Machines

Servo systems replace mechanical transmission with digital motion control.

Technical advantages:

✅ High positioning accuracy

✅ Fast response speed

✅ Reduced mechanical wear

✅ Flexible parameter adjustment

Servo control is especially important for multi‑size pouch production.

Film Alignment and Deviation Correction Technology

Printed packaging film requires accurate alignment.

Modern machines use: • CCD vision sensors

• real‑time image processing

• closed‑loop servo correction

This system automatically corrects film deviation, ensuring: ✅ accurate sealing

✅ stable printing position

✅ reducción de los residuos materiales

Bottom Forming and Punching Technology for Doypack

Doypack pouches require precise bottom forming.

Key technologies include: • servo positioning for bottom punching

• controlled forming pressure

• repeatable forming geometry

Accurate bottom shaping improves standing stability and pouch appearance.

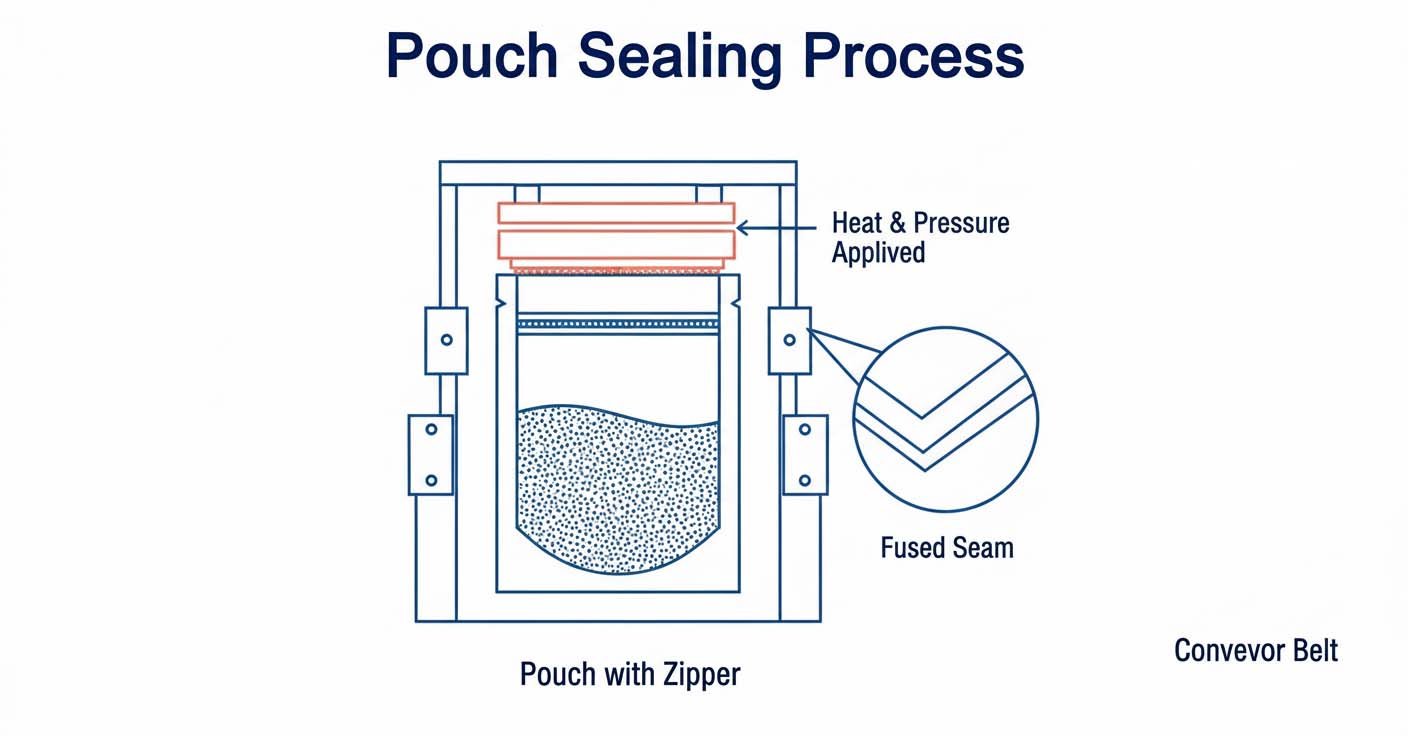

Sealing Technology and Temperature Control

Sealing quality directly affects packaging reliability.

Advanced machines integrate: • independent temperature control zones

• servo‑controlled sealing position

• post‑seal cooling systems

This ensures: ✅ strong seal strength

✅ consistent seal width

✅ improved shelf life

Bag Size Adjustment and Changeover Efficiency

Traditional machines require manual mechanical adjustments.

Servo‑driven systems allow: • digital bag length adjustment

• servo‑controlled bag width positioning

• stored recipes for fast changeover

This significantly reduces downtime during format changes.

Automation and Production Monitoring

Modern packaging machines increasingly integrate automation and digital management.

Typical functions include: • HMI operation interface

• production data monitoring

• fault diagnosis

• optional IIoT connectivity

These systems support predictive maintenance and remote management.

Maintenance and Equipment Reliability

Servo‑driven packaging machines are designed for long‑term operation.

Key design considerations: • automatic lubrication systems

• modular mechanical structure

• standardized electrical components

Proper maintenance ensures stable performance and extended service life.

Typical Applications of Servo‑Driven Doypack Machines

Servo‑driven doypack packaging machines are widely used for:

✅ food and snack products

✅ coffee and powder packaging

✅ liquid and paste filling

✅ daily chemical products

They are suitable for both medium and high‑speed production lines.

Conclusión

Servo‑driven doypack packaging machines represent a major step forward in packaging automation and precision control.

By combining servo motion, vision alignment, intelligent sealing, and digital monitoring, these machines provide reliable performance and production flexibility for modern packaging requirements.a