Intro

With over 20 years of engineering and manufacturing experience, we build high-performance blister packaging machines designed for pharmaceutical blister packaging, nutraceuticals, medical devices, and healthcare products. This guide explains what blister packaging is, how a blister pack machine works, the advantages and disadvantages, why some pharmacies are reassessing blister packs, and what drives the cost of a blister packaging machine so you can choose the right solution and maximize ROI.

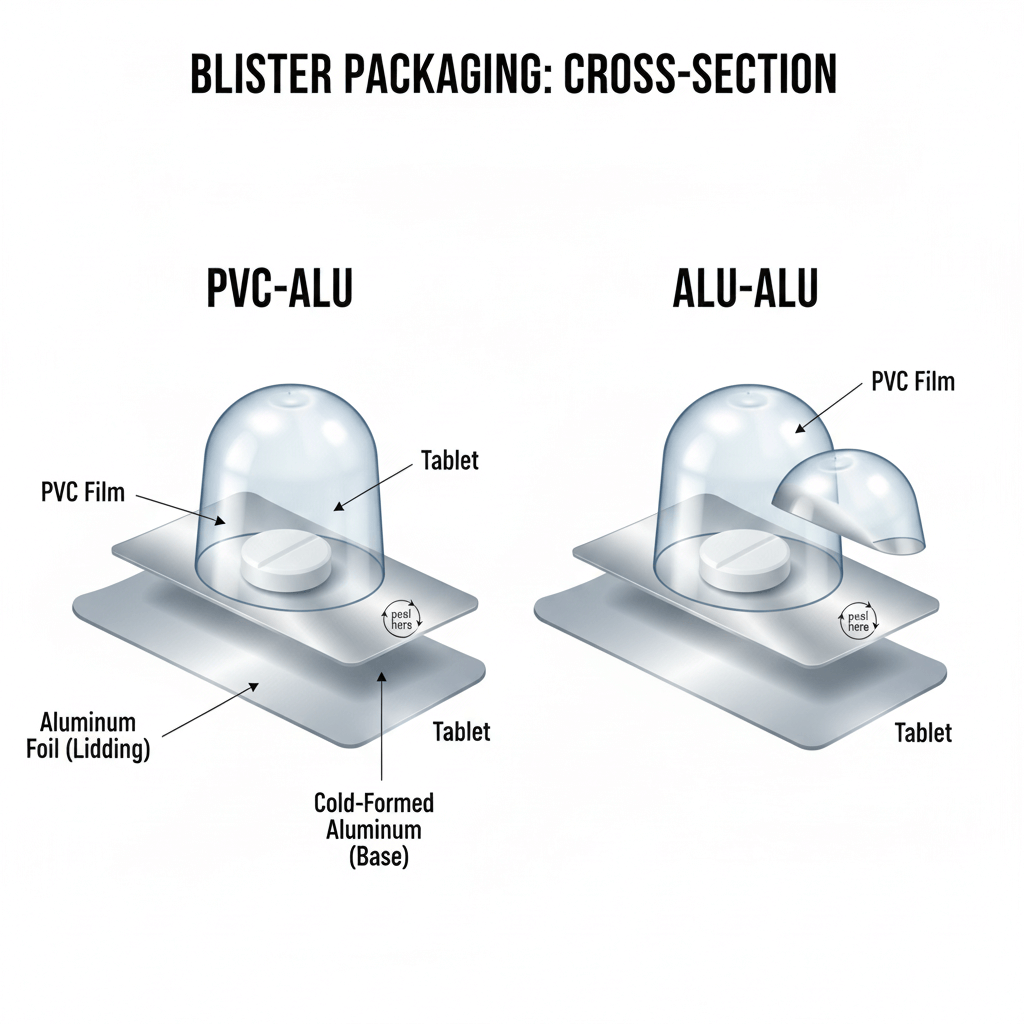

What is blister packaging? Blister packaging is a unit-dose pack formed by heating and shaping a clear or opaque thermoplastic film (such as PVC, PET, PP, or PVDC-coated films) into cavities, then sealing those cavities with a lidding material—commonly aluminum foil or paper-foil laminate. It protects tablets, capsules, ampoules, syringes, and small devices from moisture, oxygen, light, and mechanical damage while providing tamper evidence and clear product identification.

What is a blister packaging machine? A blister packaging machine (also called a blister packing machine or blister machine) automates the entire blister pack process:

- Forming: Thermoforming plastic (e.g., PVC/PVDC) or cold-forming aluminum to create cavities

- Feeding: Precisely loading tablets, capsules, or devices into cavities via dedicated feeders

- Inspection: Vision systems verify presence, shape, color, count, and reject nonconformities

- Printing and coding: Lot, expiry, 2D codes, and serialization as required

- Sealing: Heat or cold sealing with lidding materials to ensure barrier integrity

- Perforation and cutting: Creating easy-tear lines and cutting finished blister cards

- Stacking/cartoning: Collating blisters and feeding them into cartons for shipment

Where blister packs are used

- Pharmaceuticals: Solid oral dose (tablets/capsules), unit-dose hospital packs

- Nutraceuticals: Vitamins and supplements with premium presentation

- Medical devices: Lancets, test strips, small disposables

- Consumer goods: Batteries, small electronics and hardware

Key benefits for pharma and healthcare brands

- Product protection and shelf-life: Moisture and oxygen barriers; ALU-ALU for highly sensitive drugs

- Unit-dose accuracy and patient safety: Clear visibility, tamper evidence, and traceability

- Compliance and serialization: Support for 2D codes, aggregation, CFR 21 Part 11, GMP

- Brand presentation: High-quality graphics, matte/gloss finishes, custom cavity shapes

Why are some pharmacies stopping blister packs? In several markets, community pharmacies have reassessed multi-compartment compliance packs (MCPs)—the weekly pill trays prepared for individual patients. Reasons include clinical guidance questioning their universal benefit, potential stability concerns when medications are removed from original packaging, labor costs, and the need for patient-specific counseling. This trend does not typically affect manufacturer-produced unit-dose blister packs, which remain standard for solid oral dose drugs due to protection, traceability, and regulatory compliance. In short:

- Multi-compartment pharmacy-prepared packs: Some pharmacies limit use to specific cases based on clinical need.

- Manufacturer unit-dose blisters: Continue to be widely used and preferred for protection and safety.

Disadvantages of blister packaging (and how to mitigate them)

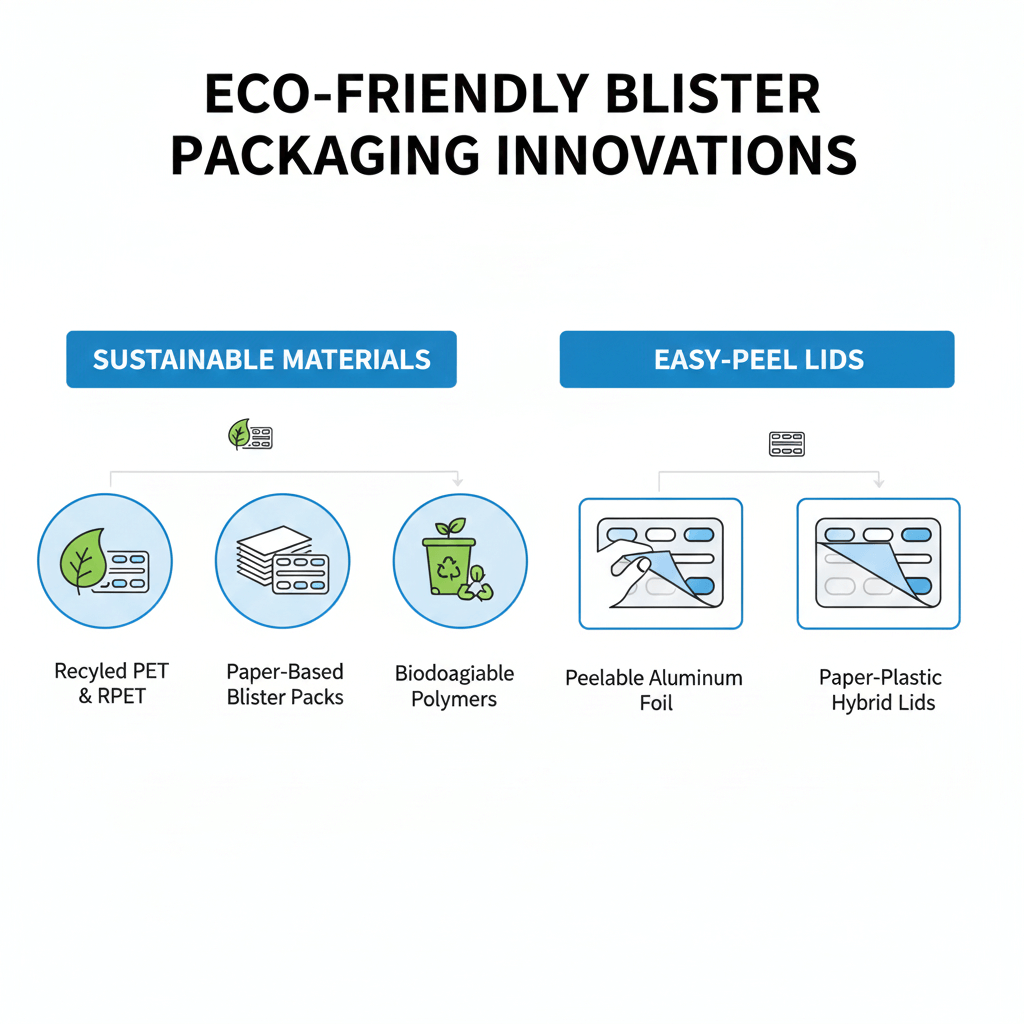

- Recycling challenges with mixed materials (PVC/ALU): Mitigate with monomaterial films (PET/PP) or recyclable lidding; offer take-back programs where available.

- Not ideal for liquids or highly irregular shapes: Use specialized blisters, sachets, or bottles for non-solid doses.

- Elderly or dexterity issues opening packs: Use senior-friendly, easy-peel lidding with clear opening cues.

- Tooling changeover time for frequent SKU switches: Choose quick-change tooling and modular feeders to reduce downtime.

- Material cost vs bottles for large counts: Use blisters for unit-dose accuracy, stability, and compliance-driven SKUs where value is higher.

How much does a blister packaging machine cost? Costs vary widely depending on speed, forming area, materials (PVC/PVDC vs ALU-ALU), automation, inspection, and serialization. Brands like Pharmaworks and Pam Pac offer different configurations, and final pricing depends on options and compliance packages. Typical market ranges:

- Entry-level/semi-automatic blister pack machine: Approx. USD 30,000–80,000

- Mid-range servo blister packaging machine (thermoform, 150–300 blisters/min): Approx. USD 120,000–250,000

- High-speed lines with integrated cartoning, vision, and serialization (300–800+ blisters/min): Approx. USD 400,000–1,000,000+

Price drivers

- Throughput and forming area

- Material compatibility (PVC/PVDC, ALU-ALU, child-resistant/senior-friendly)

- Automatic feeding systems and changeover design

- Vision inspection and reject handling

- Serialization, aggregation, CFR 21 Part 11 compliance

- Validation support (DQ/IQ/OQ), documentation, and after-sales service

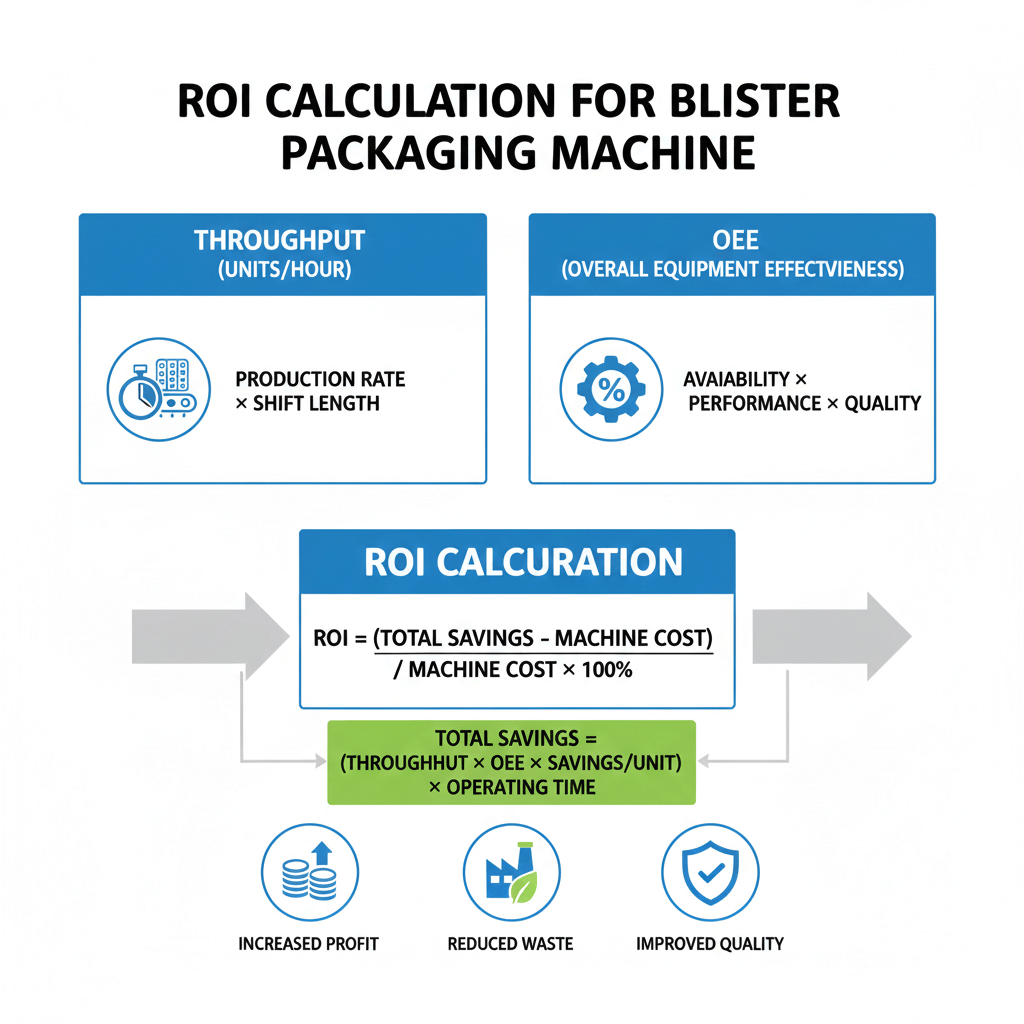

Quick ROI illustration If a mid-range line runs at 250 blisters/min, 2 shifts/day, 5 days/week, OEE 80%, that’s roughly 1.2–1.5 million blister cards/month. When combined with reduced rejects via vision inspection and faster changeovers, payback periods of 12–24 months are common for high-volume SKUs.

Our blister packaging solutions (examples)

- Compact Unit-Dose Line: For small/medium batches, fast changeovers, perfect for contract manufacturing and hospital packs

- Mid-Range Servo Line: 150–300 blisters/min, robust inspection, quick-change tooling, compatible with PVC/PVDC and ALU-ALU

- High-Speed Integrated Line: 300–800+ blisters/min with auto feeders, cartoning, serialization and aggregation ready

Core technical features

- Forming: Thermoforming (PVC/PVDC, PET, PP) and cold-form ALU-ALU support

- Sealing: Precise temperature/pressure profiles for consistent seal integrity

- Feeding: Tablet/capsule bowl feeders, brush box, vacuum pick-and-place, and device-specific solutions

- Inspection: Color/shape/position verification, missing product detection, foil defect detection

- Coding: TIJ/CIJ/laser, 2D codes, serialization, and Part 11-compliant data handling

- Changeover: Tool-less or low-tool change parts, recipe management, guided setup

Compliance and validation

- cGMP design with stainless-steel contact surfaces

- Documentation and support for DQ/IQ/OQ

- CFR 21 Part 11-ready controls for audit trails and electronic records

- CE-marking and safety interlocks

Service and support

- Turnkey installation and operator training

- Preventive maintenance programs and OEM spare parts

- Remote diagnostics and on-site support

- Global service coverage

FAQ

- What’s the difference between a blister packing machine and a blister packaging machine? They refer to the same type of equipment; “blister pack machine” and “blister machine” are also common terms.

- Can you run both PVC/PVDC and ALU-ALU on the same line? Yes, with the right forming station and tooling. Some lines are thermoform-only; cold-form requires dedicated capability.

- How long does tooling changeover take? With quick-change design, 15–45 minutes is typical depending on format and feeders.

- Do you support serialization? Yes—integrated coding, cameras, and data management with aggregation to cases and pallets.

- Lead time? Typically 10–20 weeks depending on configuration, validation requirements, and current capacity.

Call to action Ready to improve uptime, reduce rejects, and elevate your brand’s pharmaceutical blister packaging? Contact us for a tailored proposal, sample runs, and a detailed ROI calculator based on your SKUs, materials, and throughput targets.