Hero Introduction

Automatic tablet press machines—also known as tableting presses—are critical equipment for pharmaceutical, nutraceutical, candy, and specialty chemical manufacturers. These machines compress granulated or powdered materials into consistent tablets at scale, ensuring dose uniformity, structural integrity, and compliance with GMP standards. Whether you need high-speed rotary tablet presses for mass production or single-punch presses for R&D and small batches, understanding the technology, compliance, service, and cost landscape will help you select the right solution.

What Is a Tablet Press?

A tablet press machine uses mechanical pressure to compress powder into solid tablets. The key components typically include:

Hopper and feed frame for powder flow

Dies and punches (single punch or rotary multi-station)

Compression rollers applying precompression and main compression forces

Ejection mechanism and chute for finished tablets

Electronic controls for speed, pressure, and weight adjustment

Industries and Applications:

Pharma: prescription tablets, OTC, and generics (GMP-compliant configurations)

Nutraceuticals: vitamins, minerals, herbal tablets

Confectionery: candy tablets and breath mints

Specialty chemicals: catalytic tablets, detergents, desiccants

Types of Tablet Press Machines

Single Punch Tablet Press (manual or semi-automatic): Ideal for R&D labs, small pilot runs, and custom formulations. Examples: tablet press machine single punch for powder; tablet press electronic machine single punch.

Rotary Tablet Press (automatic): Multi-station tableting press delivering high throughput for pharma and nutraceuticals. Examples: tabletting press machine automatic pharma, tabletting press machine automatic rotary.

Typical Specifications

Tooling: Compatible with standard B/D tooling; custom shapes possible

Diameter range: From small (e.g., 5.5 mm) to larger formats (e.g., up to 45 mm) depending on model

Output: From a few thousand tablets/hour (single punch) to hundreds of thousands/hour (rotary)

Control Features: Tablet weight, thickness, hardness control; real-time monitoring and data logging for compliance

Is It Legal to Own a Tablet Press?

In many countries, owning a tablet press for legitimate industrial, pharmaceutical, nutraceutical, or confectionery purposes is legal. However, laws vary by jurisdiction. Some regions require registration, documentation of intended use, or inspections, especially to prevent illicit manufacturing. Businesses should:

Purchase from reputable suppliers with clear documentation

Maintain compliance records, SOPs, and traceability

Consult local regulatory authorities and legal counsel before purchase

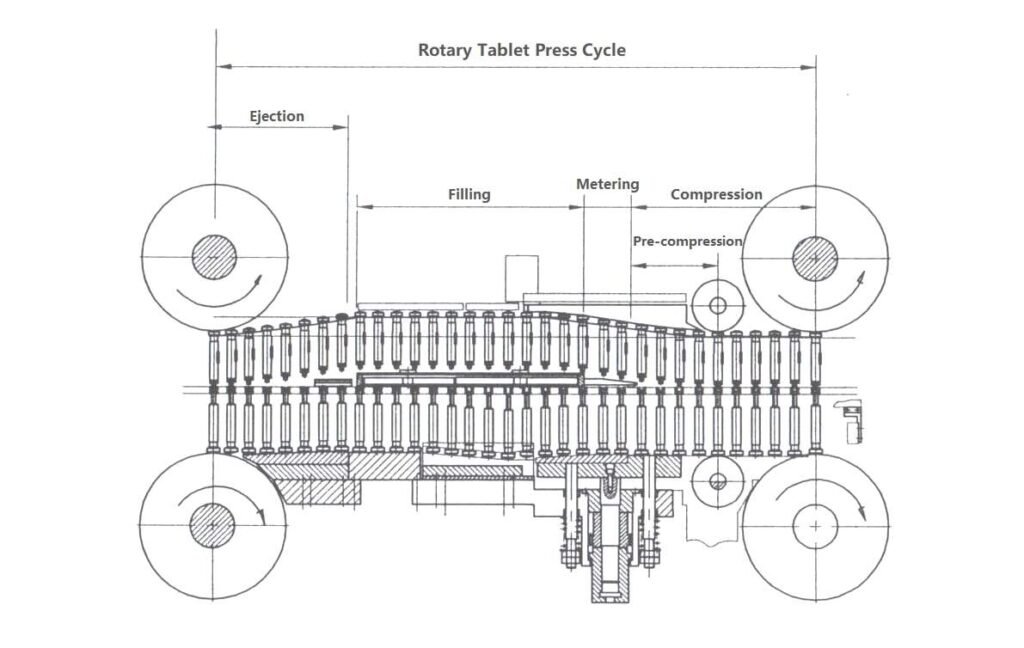

How a Tablet Press Works: From Powder to Tablet

1.Powder feeding and de-aeration

2.Die fill and level control

3.Precompression removes air and stabilizes the fill

4.Main compression sets final hardness and thickness

5.Ejection and dedusting

6.Quality checks: weight variation, hardness, friability

Automatic Tablet Press vs. Manual/Semi-Automatic

Automatic rotary presses: Highest output, consistent quality, integrated safeguards, electronic controls, 21 CFR Part 11-ready data logging (model dependent).

Manual/semi-automatic: Lower throughput, higher operator involvement, suited for prototyping and limited runs.

Are There Alternatives to a Tablet Press?

Capsule filling: For powders better suited to encapsulation or where tablet hardness is challenging

Sachet or stick pack filling: For granular products intended for dissolution

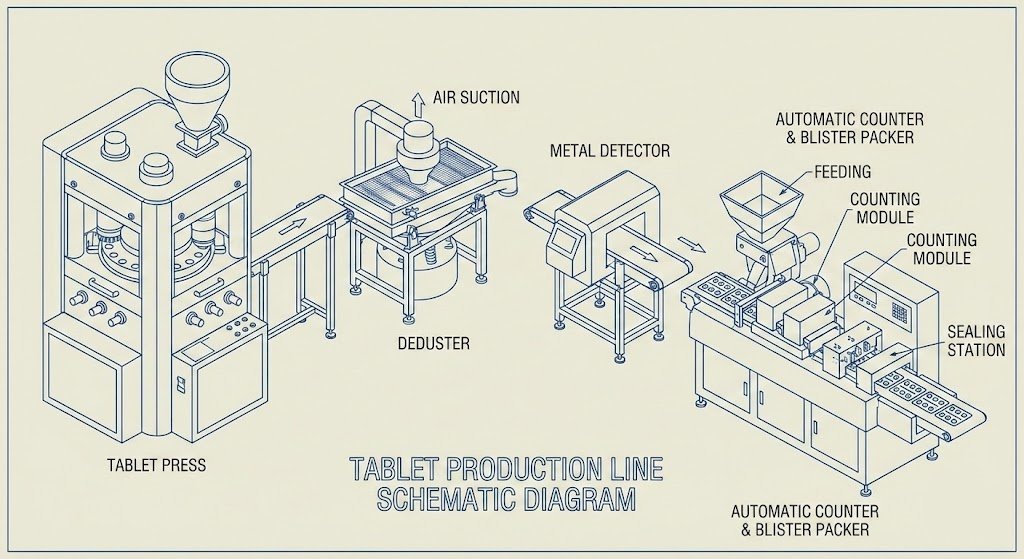

Agglomeration/granulation formats (e.g., pellets) used with alternative delivery Downstream related equipment includes automatic tablets counting machines and automatic tablet sealing solutions for packaging.

Do I Need Training to Operate a Pill/Tablet Press?

Yes. Operators should be trained in:

Machine setup and changeover

GMP hygiene and cross-contamination prevention

In-process controls: weight, hardness, thickness checks

Safety: guarding, emergency stops, lock-out/tag-out

Cleaning validation and documentation Most suppliers provide commissioning and training packages.

How Often Should a Tablet Press Be Serviced?

Service intervals depend on usage, materials, and environment. Typical guidance:

Daily: Clean down, visual inspection, lubrication checks (per SOP)

Weekly: Inspect dies/punches, seals, feed frame, compression rollers

Monthly/Quarterly: Calibration of sensors and controls; check bearings and drives

Annually: Full preventive maintenance, wear part replacement, validation A planned preventive maintenance schedule reduces downtime and ensures compliance.

Disadvantages of Tablet Punching Machines (and Mitigations)

Tooling wear: Requires routine inspection and replacement; choose hardened tool steel and proper lubrication.

Powder flow issues: Some blends segregate; improve granulation, use baffles or optimized feed frames.

Dust and cross-contamination risk: Implement dedusting, dust extraction, and strict cleaning SOPs.

Setup complexity: Rotary presses need careful alignment; invest in operator training and documented procedures.

Upfront cost: High-quality automatic tablet presses are capital-intensive; mitigate with lifecycle ROI and throughput gains.

How Much Is a Tablet Press?

Indicative ranges (vary widely by brand, compliance features, and capacity):

Single punch tablet press: Lower five figures USD for lab-grade units

Automatic rotary tablet press: Mid-five to six figures USD and above for GMP-compliant models with electronic controls, data integrity, and high throughput Accessories that impact budget:

Tooling sets (custom shapes/sizes)

In-line deduster and metal detector

Automatic tablets counting machines and sealing/packaging lines

Validation and documentation packages

Key Buying Considerations

Compliance: GMP design, documentation, and validation support

Throughput and tablet size range: e.g., 5.5 mm to 45 mm depending on product portfolio

Materials: Corrosion-resistant, cleanroom-ready surfaces

Controls and data: Electronic monitoring, audit trails, recipe management

Safety: Guarding, interlocks, overload protection

Support: Installation, training, spare parts, and preventive maintenance plans

Call to Action

Ready to scale compliant tablet production? Contactez nous for a specification review, sample runs with your formulation, and a tailored quote for an automatic rotary tablet press or single-punch solution.