Section 1: What is Horizontal Form Fill Seal (HFFS)?

Horizontal Form Fill Seal (HFFS) is an automated packaging process where a machine forms, fills, and seals flexible pouches in a horizontal orientation. The machine unwinds rollstock film, forms the pouch (including gussets and spout areas if required), doses product via multi-head weighers or flow meters, and seals the pouch with precise heat and pressure. HFFS systems are ideal for doypack pouches, standing pouches, and spouted pouches used for sauces, beverages, gels, powders, granules, and snacks.

Key advantages of HFFS:

– Premium pouch formats: doypack pouch, stand up pouch, spout pouch

– High speed with excellent repeatability and seal integrity

– Lower packaging material waste, consistent pouch dimensions

– Integration with CIP-rated liquid fillers and multi-head weighers

– Superior brand presentation with zipper, spout, and laser scoring options

Section 2: Types of Form Fill Seal Machines Form fill seal machines come in several configurations to match product characteristics and throughput targets:

- Horizontal Form Fill Seal (HFFS):

- Best for premium stand up pouches and doypack pouch formats

- Supports spout pouch packaging machine modules for liquids

- Excellent for products needing wide seal areas and complex features (zippers, spouts, reclose)

- Vertical Form Fill Seal (VFFS):

- Film is formed into a vertical tube; ideal for pillow bags, sachets, and some gusseted bags

- Often used for powders, granules, snacks

- Typically higher speed for simple bag styles, lower material utilization for premium pouches

- Automatic Rotary Filling Standing Pouch Machine:

- Indexing rotary stations for premade standing pouch packaging machine applications

- Great for lower to medium speeds using premade pouches with high flexibility

- Fast changeovers and excellent format variety

- Doypack Automatic Packing Machine:

- Specialized for doypack pouch styles; can be rollstock (HFFS) or premade (rotary)

- Automates opening, filling, sealing, code printing, and inspection

Section 3: HFFS vs VFFS – What’s the Difference? While both are FFS technologies, HFFS and VFFS serve distinct needs:

- Orientation and format:

- HFFS: Horizontal web handling; excels at doypack pouch and stand up pouch packing machine applications

- VFFS: Vertical web forming; best for pillow bags, simple gusset bags

- Product suitability:

- HFFS: Liquids, viscous products, powders and granules needing premium shelf display; integrates spout pouch packaging machine modules

- VFFS: Free-flowing powders, snacks, rice, sugar—high speeds for basic formats

- Features and aesthetics:

- HFFS: Zippers, spouts, laser-tear, shaped pouches, reinforced corners; superior print registration and seal symmetry

- VFFS: Simpler configurations, limited advanced features compared to HFFS

- Throughput and cost:

- VFFS often delivers higher speeds for basic bags with lower initial machine cost

- HFFS delivers premium pouch quality and brand differentiation with higher machine investment but better retail impact and consumer convenience

Section 4: Stand Up Pouch and Doypack Solutions To meet modern retail demands, brands are shifting from rigid containers to flexible pouches. HFFS systems enable:

- Standup pouch filling machine capabilities for powders, granules, and liquids

- Doypack packing machine automatic operation from rollstock with reduced labor

- Integration with spout insertion for spout pouch packaging machine lines

- Quality control modules: inline leak detection, vision inspection, weight checking

- Quick changeover between formats and sizes to support SKU variety

Section 5: Cost Insights – Bosch Packing Machine and Market Ranges The cost of “Bosch packing machine” (now branded Syntegon following Bosch Packaging Technology’s transition) varies by model and configuration. In general:

- VFFS entry-level systems: typically lower cost for simple pillow bags

- HFFS systems for doypack/stand up pouches: higher investment due to advanced forming, sealing, and special features (zippers, spouts, shape forming)

- Automatic rotary filling standing pouch machine (premade pouch): mid-range to high, depending on stations, automation, and integrations

Indicative market ranges (for reference only; actual pricing depends on options, speed, and region):

- VFFS basic: tens of thousands USD+

- HFFS doypack from rollstock: mid-five to low-six figures USD+

- Rotary premade standup pouch lines: mid-five to six figures USD+

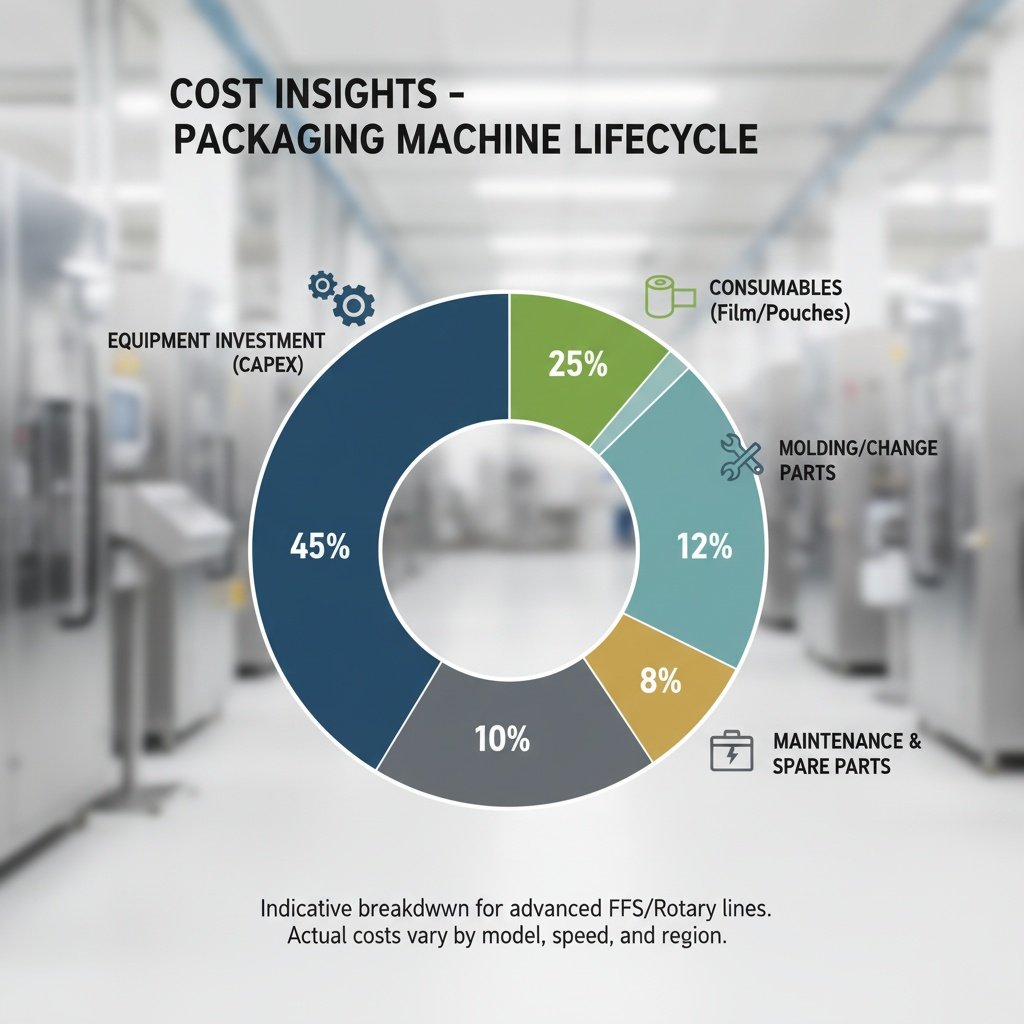

When comparing costs, consider:

- Throughput (pouches/min)

- Changeover time and format flexibility

- Film vs premade pouch cost per unit

- Integration with spout insertion, zipper applicators, and product dosing

- After-sales support, spare parts availability, and energy consumption

Section 6: How to Choose the Right HFFS Machine

- Define pouch format: doypack pouch, stand up pouch, spout pouch

- Specify product: liquid vs powder, viscosity, fill accuracy requirements

- Target speed: balance output with product handling and quality controls

- Film and sustainability: recyclable mono-materials, thinner gauges, easy-open features

- Line integration: upstream mixers/weighers, downstream case packing, coding and inspection

- Service and training: remote diagnostics, local service network, spare parts logistics