Introduction

As a professional engineer with over 20 years of experience in the tablet press industry, I’ve encountered nearly every operational issue that can affect rotary tablet presses. The GZPK-51 Rotary Tablet Press, designed and manufactured by HIJ Machinery, is one of the most advanced and reliable high-speed tablet compression machines used in pharmaceutical, health supplement, and chemical production lines worldwide.

However, even with a precise design and robust structure, consistent performance depends on proper troubleshooting, regular maintenance, and operator skill. This detailed guide will help you identify, diagnose, and solve common problems associated with the GZPK-51 rotary tablet press, ensuring stable production and optimum product quality.

Understanding the GZPK-51 Rotary Tablet Press

The GZPK-51 is a high-speed, double-sided rotary tablet press featuring 51 stations that offer exceptional productivity and precision. Designed for continuous large-scale production, it can achieve excellent weight uniformity, high hardness consistency, and smooth tablet surfaces.

Main Technical Highlights

- Stations: 51

- Maximum Output: Up to 420,000 tablets/hour

- Max Pressure: 100 kN

- Tablet Diameter: Up to 25 mm

- Operation Control: PLC with touch-screen interface

- Compliance: GMP & CE certified

Its intelligent lubrication, stable turret structure, and advanced dustproof sealing system make the GZPK-51 one of the most durable tablet presses for demanding production environments.

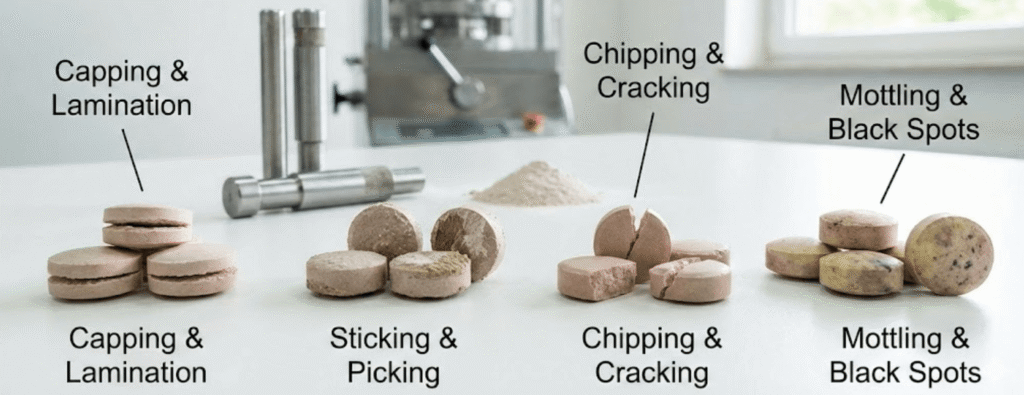

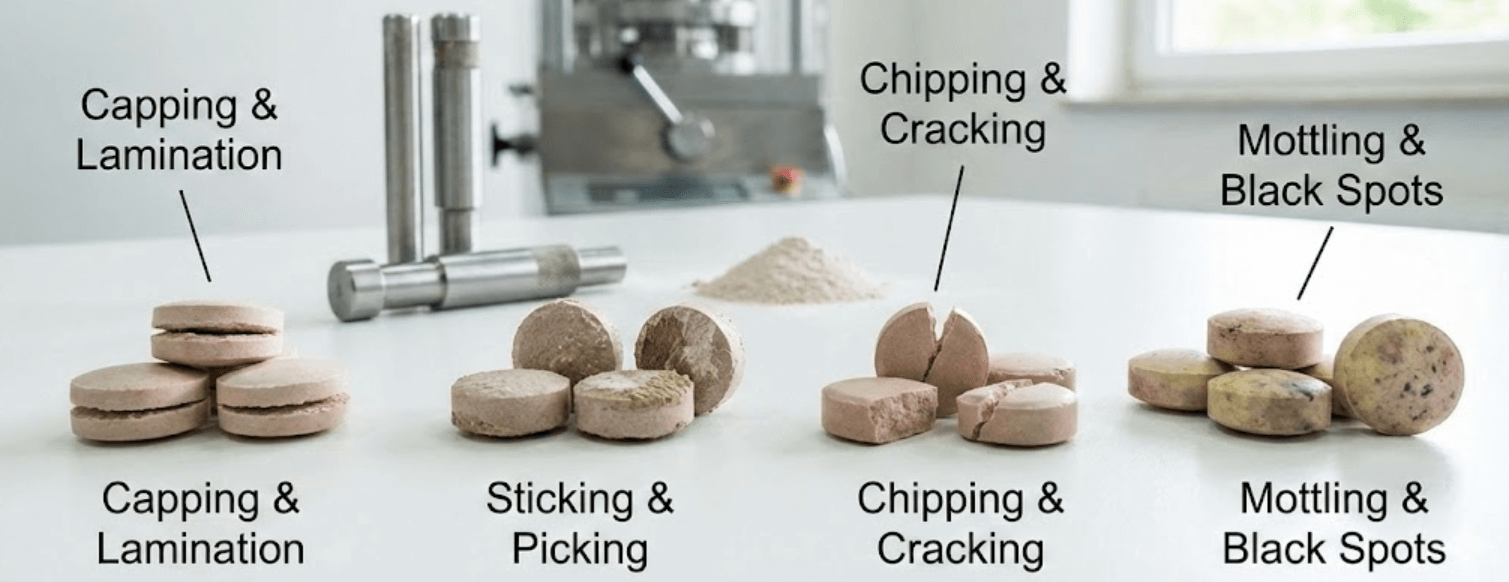

Common Problems and Symptoms

Even high-quality machines may encounter minor issues during continuous operation. Understanding early symptoms can prevent production interruptions or costly repairs.

| Problem | Common Symptoms |

|---|---|

| Tablet Weight Variation | Inconsistent tablet weight, powder overflow |

| Low Tablet Hardness | Tablets breaking easily or crumbling |

| Uneven Tablet Surface | Visible surface defects or thickness variation |

| Excessive Vibration or Noise | Unusual mechanical noise, shaking |

| Powder Leakage | Visible powder dust around turret |

| Low Output | Reduced tablet per hour count |

| Punch and Die Wear | Scratches, sticking, pressure inconsistency |

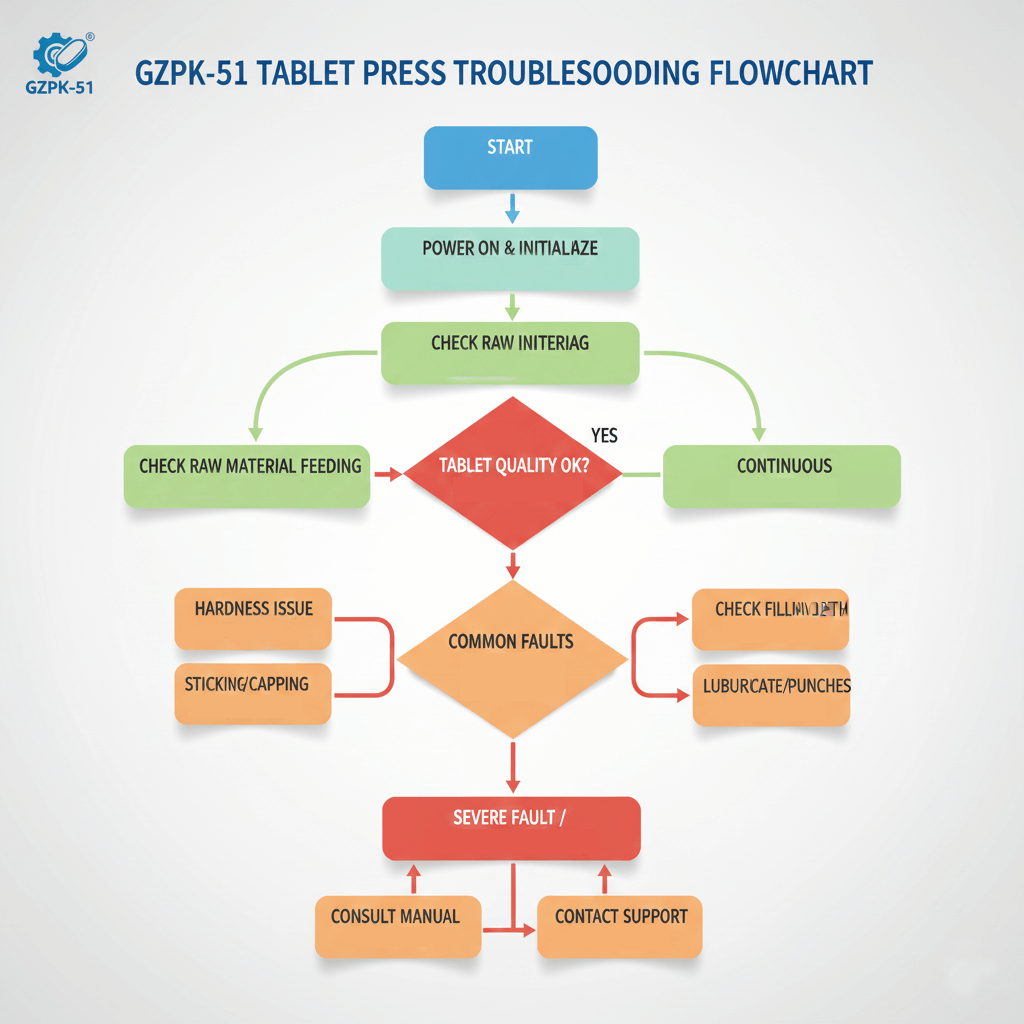

Step-by-Step Troubleshooting Guide

The following procedures are based on my two decades of hands-on experience in diagnosing and maintaining rotary tablet presses like the GZPK-51.

1. Tablet Weight Variation

Possible Causes:

- Inconsistent powder flow

- Uneven feeder speed

- Worn punches or dies

Solutions:

- Calibrate the feeder speed and agitation rate.

- Clean the feed frame and ensure continuous material flow.

- Replace worn tooling and inspect tablet weight sensors.

2. Low Tablet Hardness

Possible Causes:

- Insufficient compression force

- Moisture imbalance in granules

Solutions:

- Adjust the pre-compression and main compression values.

- Test granule moisture (ideal 3%–5%).

- Verify correct powder formulation to maintain cohesion.

3. Uneven Tablet Surface

Possible Causes:

- Die misalignment

- Incorrect scrapper or fill cam setting

Solutions:

- Inspect die seating positions and alignment.

- Adjust scrapper blade clearance.

- Perform a slow rotation test after adjustments.

4. Excessive Vibration or Noise

Possible Causes:

- Turret imbalance

- Worn main bearings or cam rollers

- Poor lubrication

Solutions:

- Conduct turret balancing procedures.

- Replace bearings and lubricate all critical shafts.

- Ensure proper leveling of the machine base.

5. Powder Leakage

Possible Causes:

- Damaged seals or worn feeder cover

- Excessive feeder rotation speed

Solutions:

- Replace sealing rings and clean feeding channels.

- Reduce feeder speed to 30–40 rpm range.

- Check dust collection system efficiency.

6. Low Output

Possible Causes:

- Improper fill depth

- Tablet adhesion or sticking on punches

Solutions:

- Increase fill depth setting within acceptable limits.

- Polish tooling surfaces and use food-grade anti-sticking agents.

- Regularly clean lower punches and dies to prevent residue buildup.

7. Punch and Die Excessive Wear

Possible Causes:

- Abrasive formulation materials

- Poor cleaning habits or contaminated lubricants

Solutions:

- Choose hard chrome or carbide-coated tooling.

- Implement a detailed cleaning protocol after each batch.

- Store punches in moisture-controlled cabinets.

Preventive Maintenance Tips

Preventive maintenance is key to maximizing the lifespan of the GZPK-51 and ensuring peak performance.

Daily Checks

- Remove powder residue after every production run.

- Lubricate punch guides and turret tracks.

- Visually check for oil or powder leaks.

Weekly Maintenance

- Inspect die table surface polishing and flatness.

- Verify press pressure calibration and feeder consistency.

- Tighten turret and housing bolts if necessary.

Monthly Maintenance

- Recalibrate compression sensors and weight check systems.

- Replace worn out seals, O-rings, and feeder brushes.

- Test emergency stop buttons and safety interlocks.

Maintaining a clear logbook for all activities ensures traceability and compliance with GMP or ISO quality systems.

Optimization Recommendations

1. Balancing Speed and Pressure

For high-speed tablet production, balance turret rotation speed with compression force to maintain uniform hardness and avoid punch overload.

2. Advanced Control System

Use HIJ Machinery’s optional intelligent control system to monitor compression force, ejection pressure, vibration, and temperature data in real-time for predictive maintenance.

3. Operator Training

A well-trained operator dramatically reduces breakdowns. HIJ Machinery provides free technical training with every GZPK-51 purchase.

4. Customized Compression Profiles

Different formulations require unique compression dwell times. Fine-tune the pre- and main-pressure ratio to improve product yield and reduce sticking.

5. Use Genuine Spare Parts

Always source replacement parts directly from HIJ Machinery to ensure compatibility and extended lifespan.

Why Choose HIJ Machinery

With decades of engineering excellence, HIJ Machinery has become a trusted name in the manufacture of high-performance tablet presses across more than 30 countries. Our equipment, including the GZPK-51, meets stringent GMP and CE standards, providing pharmaceutical and nutraceutical manufacturers with reliability, precision, and value.

Advantages of Choosing HIJ Machinery:

- 20+ years of specialized engineering experience

- Full service from installation to training and maintenance

- Global partnerships and prompt spare parts delivery

- Customized tablet press solutions for diverse formulations

We don’t just sell machines—we deliver performance, longevity, and confidence.

Conclusion

The GZPK-51 Rotary Tablet Press is a technologically advanced machine designed for consistent, high-speed tablet production. When properly maintained, it delivers exceptional stability, precision, and minimal downtime.

By following this troubleshooting and maintenance guide, you can quickly diagnose typical problems, restore optimal performance, and extend equipment life.

For further assistance, professional maintenance, or spare parts supply, contact HIJ Machinery’s engineering team.

Our 20-year expert engineers are ready to provide customized on-site support and ensure your GZPK-51 operates flawlessly.

📩 Contact us today at HIJ Machinery to schedule a technical consultation or request original GZPK-51 spare parts.