1. Pendahuluan

The Manufacturing Reality in 2025

In 2025, manufacturers across the globe are facing a perfect storm: persistent labor shortages dan rising material costs. Finding and retaining skilled operators has become increasingly difficult, while packaging materials continue to rise in price due to sustainability regulations and supply chain volatility.

For factory owners and production managers, this means one thing: traditional manual packaging is no longer sustainable.

Packaging Machines Are No Longer Just Machines

Modern packaging machinery is no longer a simple production tool.

It has evolved into a fully automated profit engine—capable of reducing labor dependency, minimizing material waste, and delivering predictable output day after day.

Automation today is not about replacing people; it’s about protecting margins.

Industry Data That Matters

According to PMMI’s 2025 State of the Industry Report, the U.S. packaging machinery market alone is projected to exceed $11.5 billion, driven almost entirely by manufacturers investing in automation to combat labor shortages and rising operating costs.

What You’ll Learn in This Guide

In this ultimate 2025 guide, you’ll discover:

- The latest packaging machinery trends for 2025–2026

- A clear VFFS vs. HFFS comparison for smart machine selection

- How to calculate real ROI, not just machine price

- What AI, robotics, and smart factories mean for packaging’s future

2. 2025–2026 Packaging Machinery Market Trends

Trend 1: Sustainability & Material Thinnability

Sustainability is no longer optional—it’s enforced by regulation.

New packaging machines must reliably handle:

- Thinner gauge films

- Biodegradable and recyclable materials

- Compostable laminates with inconsistent tensile strength

This shift is driven largely by European and North American regulations such as PPWR (Packaging and Packaging Waste Regulation).

✅ What it means for buyers:

Machines with advanced tension control, servo-driven sealing, and adaptive film tracking are now essential.

Trend 2: Smart Packaging & IIoT (Industrial Internet of Things)

The biggest leap forward is predictive maintenance.

Instead of reacting to breakdowns, modern machines:

- Monitor bearing wear

- Track temperature and vibration

- Alert operators before failures occur

This reduces unplanned downtime and maintenance costs dramatically.

✅ Real benefit:

Less downtime = more production hours = faster ROI.

Trend 3: Compact & Modular Machine Design

As factory rent increases worldwide, manufacturers demand:

- Small footprint machines

- Quick changeover between bag styles

- Modular designs that scale with growth

One machine, multiple SKUs, minimal downtime.

3. VFFS vs. HFFS: Which One Fits Your Production Line?

This is one of the most searched comparisons by B2B buyers—and for good reason.

VFFS vs. HFFS Comparison Table

| Feature | VFFS (Vertical Form Fill Seal) | HFFS (Horizontal Form Fill Seal) |

|---|---|---|

| Best For | Granules, liquids, powders, snacks | Solid, single, fragile products |

| Kecepatan | High (50–100+ bags/min) | Medium to high |

| Floor Space | Compact (vertical footprint) | Larger footprint |

| Changeover | Fast (modular formers) | Slower |

| Cost | Lower entry cost | Higher initial investment |

✅ Pro Tip from Packaging Engineers

- Choose VFFS if you pack coffee powder, nuts, frozen vegetables, or rice.

- Choose HFFS if you pack biscuits, chocolate bars, medical devices, or premium zipper pouches.

4. The Financials: Calculating Your Packaging Machine ROI

Why Price Alone Is Misleading

Many buyers focus only on machine price, ignoring Total Cost of Ownership (TCO).

The real question is:

How fast does the machine pay for itself?

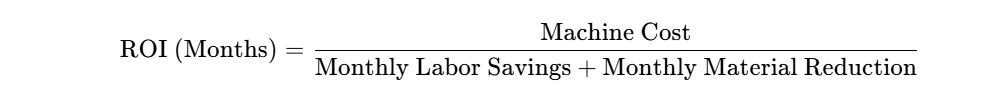

ROI Calculation Formula

Case Study: Realistic ROI Scenario

Scenario:

A mid-sized food manufacturer replaces manual packing with a fully automatic VFFS machine.

Data:

- Labor reduction: 3 workers × 3,000=∗∗3,000 = **9,000/month**

- Material waste reduction: $500/month

- Machine cost: $50,000

Result:

✅ ROI = 5.2 months

After that, the machine becomes pure profit.

5. 5 Questions to Ask Before Buying a Packaging Machine

1. What is the real throughput speed?

Ask for cruising speed, not maximum speed.

2. Can it handle multiple bag styles?

Pillow bag, gusseted, quad seal—flexibility matters.

3. Are spare parts proprietary?

Generic components = lower lifetime cost.

4. Is the HMI intuitive?

A new operator should learn it in under 2 hours.

5. Does it meet 2025 safety standards?

Look for CE, UL, OSHA compliance.

6. Future Outlook: AI and Robotics in Packaging

Vision Systems

AI-powered cameras now:

- Detect seal defects

- Reject underweight packages

- Eliminate manual inspection

Cobots (Collaborative Robots)

Cobots handle:

- Case packing

- Palletizing

- End-of-line automation

They work safely alongside humans, reducing labor fatigue.

7. Conclusion & Call to Action

Key Takeaway

In 2025, the cheapest machine is rarely the best machine.

Smart buyers focus on:

- ROI

- Reliability

- After-sales support

Automation is no longer a cost—it’s a competitive advantage.

✅ CTA

Ready to calculate your automation ROI?

👉 Contact our engineering team today for a free production line assessment.

✅ Google Hot FAQs

Q: How much does an automatic packaging machine cost in 2025?

A: Entry-level semi-auto machines range from 5,000–5,000–15,000; high-speed VFFS machines cost 25,000–25,000–60,000+; custom HFFS lines can exceed $100,000.

Q: What is the difference between VFFS and HFFS?

A: VFFS forms bags vertically for loose products, while HFFS forms bags horizontally for solid items.

Q: How long does a packaging machine last?

A: With proper preventive maintenance, 10–15 years.

Q: Is automated packaging cheaper than manual labor?

A: Yes. For outputs above 10–15 bags/minute, automation usually achieves ROI within 12–18 months.