Pendahuluan

In the fast-paced world of manufacturing and logistics, efficiency is everything. For over 20 years, we have seen how the right mesin pengemasan can transform a business from a manual operation into a high-speed production powerhouse. But for many business owners and procurement managers, navigating the vast market of packaging machines can be overwhelming.

What is a packaging machine? Simply put, it is a device designed to automate the process of enclosing and protecting products for distribution, storage, sale, and use. From simple sealing devices to complex, fully automated lines, these machines ensure your products reach customers safely and professionally.

Whether you are looking for a specialized flour packaging labeling machine or a versatile packing machine for various goods, this guide will answer your most pressing questions: Which machine is used for packaging? What equipment do you need? And how can it boost your production line?

Which Machine is Used for Packaging? Exploring the Types

There is no “one-size-fits-all” solution. The answer to “Which machine is used for packaging?” depends entirely on your product type, viscosity, and packaging material. Here are the most common categories of mesin pengemasan available in the market:

1. Filling and Bottling Machines

For liquids, pastes, and powders, filling machines are essential. They ensure precise dosage, reducing product waste.

- Best for: Beverages, oils, cosmetics, and chemicals.

2. Vertical Form Fill Seal (VFFS) Machines

This is a popular type of packing machine for granular and solid products. It forms a bag from a roll of film, fills it with the product, and seals it vertically.

- Best for: Snacks, coffee beans, grains, and hardware parts.

3. Flour Packaging and Labeling Machines

Specific industries require specialized equipment. A flour packaging labeling machine is designed to handle fine powders without creating dust clouds, while simultaneously applying accurate labels for nutrition and branding. High-quality packaging machines in this niche often feature dust extraction systems and high-precision auger fillers to ensure weight accuracy.

What Equipment is Needed for Packaging? Building a Complete Line

A standalone packing machine is often just one part of the puzzle. To build a fully automated system, you need to consider the entire workflow. What equipment is needed for packaging? A complete line typically includes:

- Feeding Systems: Conveyors or screw elevators that transport raw materials into the mesin pengemasan.

- Weighing Systems: Multi-head weighers or auger fillers that ensure every package contains the exact amount of product.

- Labeling Machines: Often integrated into the line to apply barcodes, expiration dates, and brand logos.

- End-of-Line Equipment: Case packers and palletizers that prepare finished goods for shipment.

Investing in compatible packaging equipment ensures your line runs smoothly without bottlenecks.

What Does a Packing Machine Operator Do?

Many buyers worry about the complexity of new technology. They often ask, “What does a packing machine operator do?”

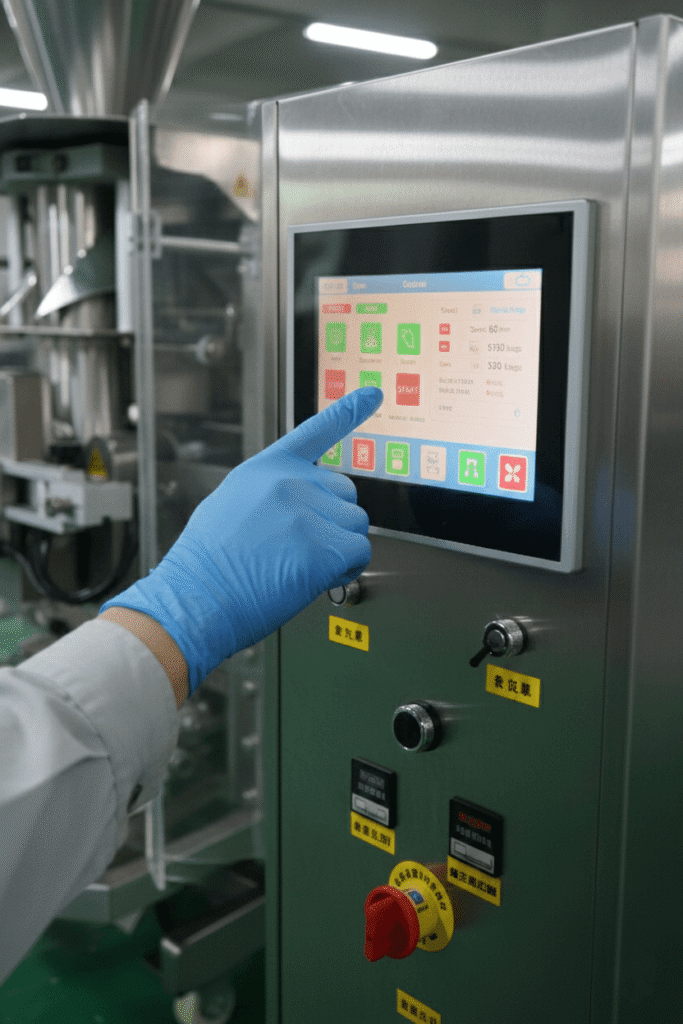

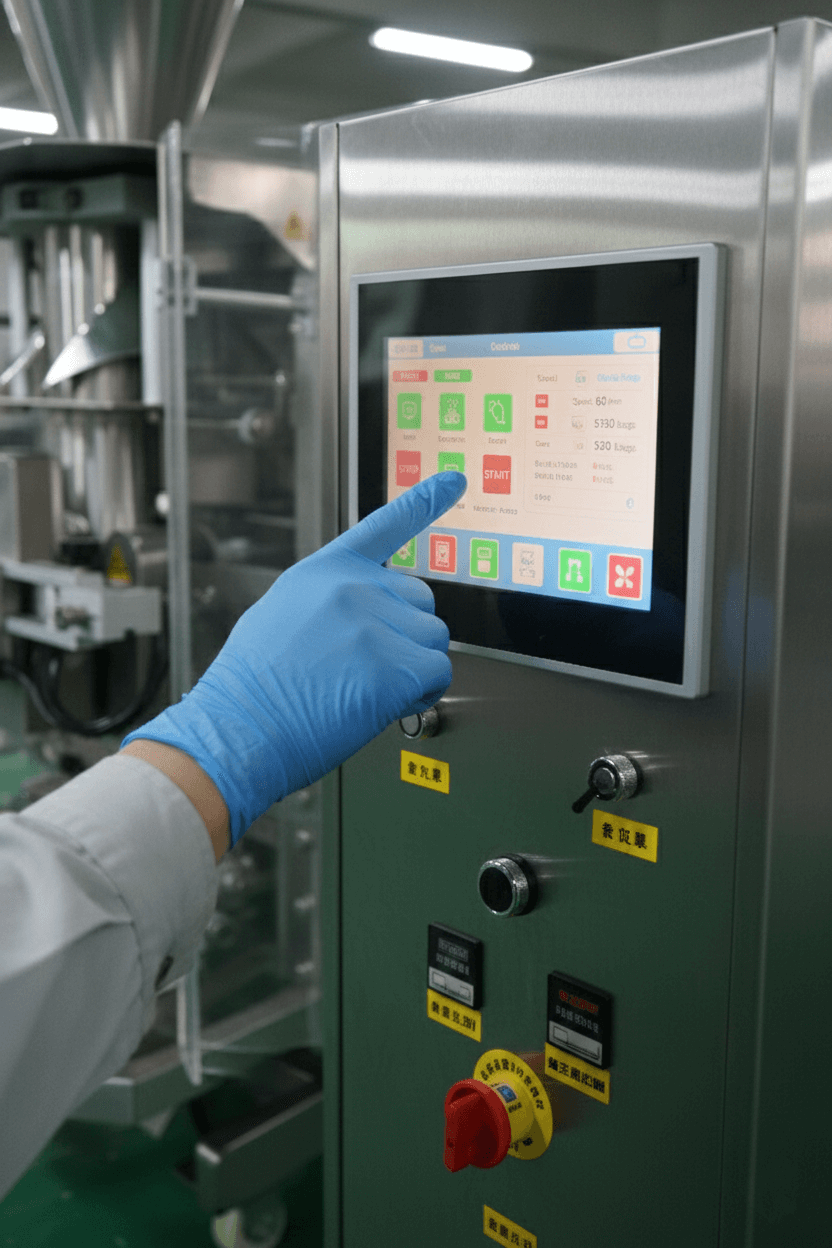

Modern packaging machines are designed with user-friendliness in mind. Today, an operator’s role is less about manual labor and more about supervision and quality control. Their key responsibilities include:

- Setting Parameters: Using a touchscreen (HMI) to input bag length, speed, and temperature settings.

- Material Loading: Replenishing film rolls, labels, or raw materials.

- Monitoring: Watching the packing machine for smooth operation and performing basic troubleshooting.

At our company, we design our mesin pengemasan to be intuitive, requiring minimal training so your operators can become proficient quickly.

Why Your Business Needs High-Quality Packaging Machines

In the competitive global market, the quality of your packaging is often associated with the quality of your product. Upgrading to professional packaging machines offers immediate ROI (Return on Investment):

- Consistency: A packing machine packaging your product ensures every bag looks identical, enhancing brand image.

- Speed: Automated machines can do the work of 10+ manual laborers, significantly increasing output.

- Cost Reduction: reduce material waste and labor costs over time.

How to Choose the Right Manufacturer

With over two decades of experience, we know that buying a mesin pengemasan is a significant investment. When selecting a supplier, look for:

- Experience: A factory with a long history ensures stability and spare parts availability.

- Customization: Can they tailor the flour packaging labeling machine to your specific bag size?

- After-Sales Support: Do they offer video technical support or engineer installation services?

Kesimpulan

Whether you are packaging flour, snacks, or hardware, the right mesin pengemasan is the engine of your business growth. Don’t settle for inefficiency.

Ready to upgrade your production line? Contact us today to discuss your specific needs. Our expert team is ready to help you find the perfect packing machine solution that fits your budget and goals.