Product Description

This machine is a kind of plastic bottle thermoforming filling & sealing equipment,it’s suitable for batch filling in pharmacy,pesticide, cosmetic, food & beverage and nutrition etc. Field for liquid & Cream material, it’s widely used for filling oral liquid,liquid pesticide & fertilizer,E-Liquid, liquid&Cream cosmetic,edible oil,beverage and liquid health care product etc.

Machine Parameters

| Max. forming depth | 12mm |

| Punch frequency | 1-25times |

| Packing material | PVC/PE,PET/PE(0.2-0.4)260×mm |

| Filling volume | 0.1-200ml |

| Toal power supply power | 7KW |

| Tensione | 380V/50Hz |

| Peso della macchina | 1000Kg |

| Overall dimension (L*W*H) | 3380×950×1800(mm) |

| Separate size (L*W*H) | 2500×950×1800(mm) |

The GGS- 118 series machines are suitable for bottle without flat bottom , and bottle with random printing or no printing. If each bottle with logo or printing image on same position, then GGS-240 series machines should be adpoted.

Caratteristiche

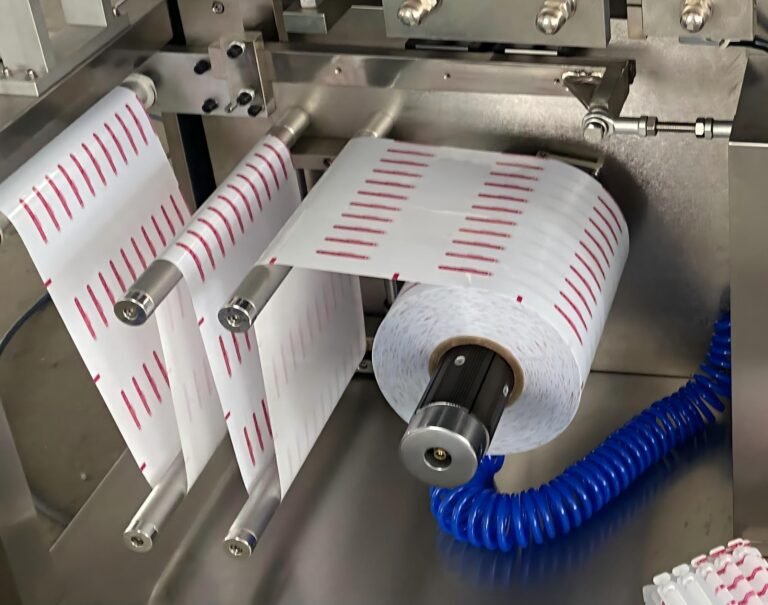

1.High capacity, high speed, high precision, and advanced motion controller. Stepless frequency conversion speed regulation control. Servo motor controls film traction device.

2.Human-machine interface, easy to operate.

3.Automatic unwinding, roll film cutting. It has positive and negative pattern alignment function with photoelectric device. The product is exquisite and beautiful, which meets high standard of packing requirements.

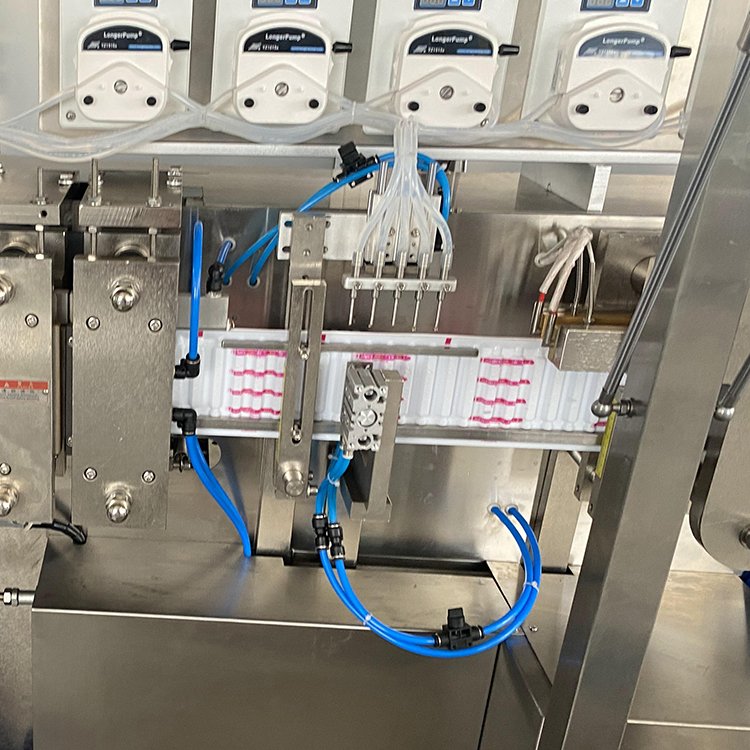

4.It adopts electronic peristaltic pump device and mechanical piston pump

control, which hasconvenient adjustment.

5.High filling accuracy with suction back function without any dripping.

6.The parts contacting with the medicine adopt high quality stainless steel 316L, and the outercover of the machine is made of SUS304 stainless steel, which meets with GMP standard.

7.As the bottom of the bottle is flat, so it can stand.

8.The cutter is individually controlled by dual servo motors, and you can cut at will if you need several pieces per board.

Our factory