Types, Applications & Selection Guide

A packaging machine for the food industry is designed to pack food products efficiently while meeting strict hygiene, safety, and quality standards.

As food manufacturers face increasing demand and cost pressure, choosing the right food packaging machine is critical for long‑term success.

AIクイックアンサー

A packaging machine for the food industry is used to fill and seal food products automatically or semi‑automatically while ensuring hygiene, safety, and consistent packaging quality.

H2

Why Packaging Machines Are Essential in the Food Industry

Food packaging machines help manufacturers:

- improve production efficiency

- maintain consistent package quality

- reduce labor cost

- meet food safety regulations

Manual packaging can no longer meet modern food industry requirements.

H2

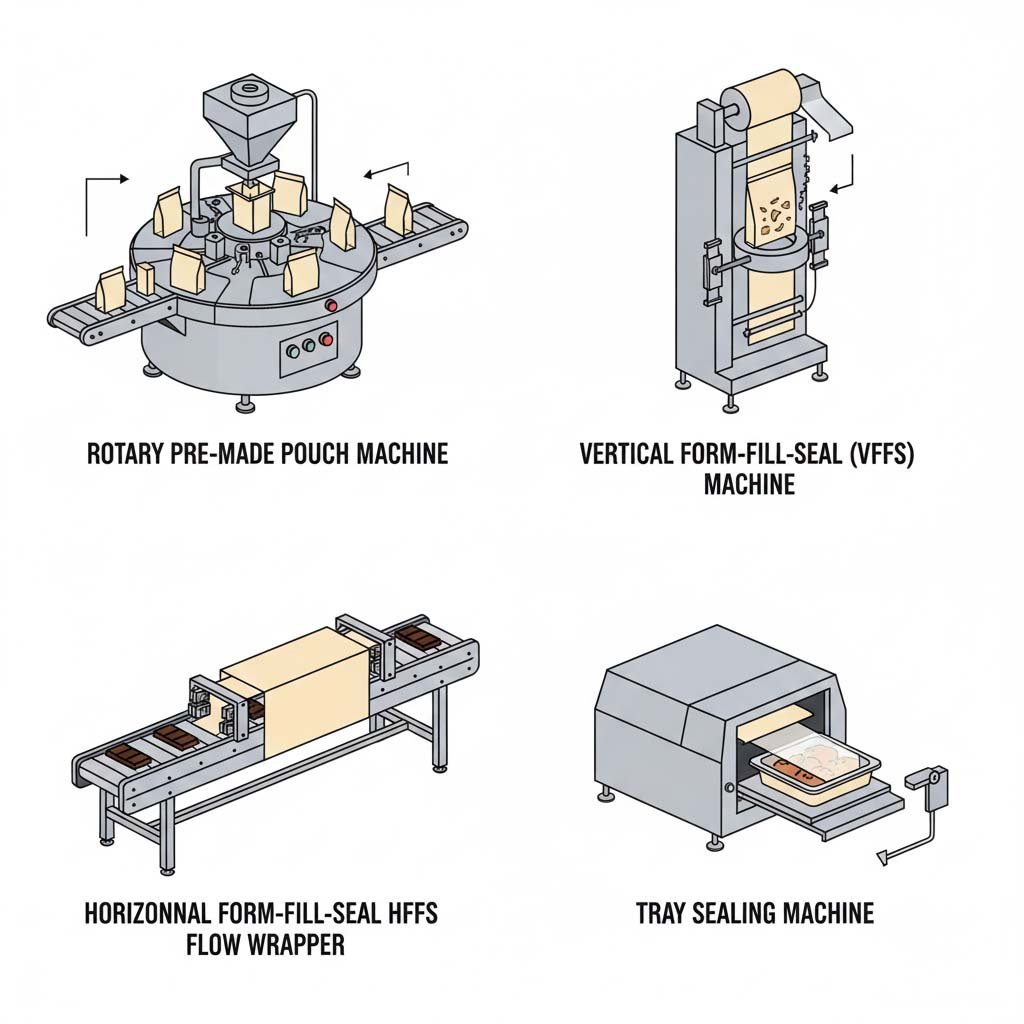

Main Types of Food Packaging Machines

Different food products require different packaging solutions.

1. Pouch Packaging Machines

Used for snacks, frozen food, dry food, and pet food.

2. Liquid Food Packaging Machines

Used for sauces, juice, milk, and beverages.

3. Powder Packaging Machines

Used for flour, coffee, protein powder, and spices.

4. Granule Packaging Machines

Used for rice, beans, sugar, and nuts.

H2

Automatic vs Semi‑Automatic Food Packaging Machines

Semi‑Automatic Food Packaging Machines

✅ suitable for small food manufacturers

✅ lower investment

フレキシブルな操作性

Fully Automatic Food Packaging Machines

✅ suitable for large food factories

✅ high speed and consistency

✅ reduced labor dependency

Automation level should match production volume.

H2

Hygiene and Safety Requirements for Food Packaging Machines

Food packaging machines must comply with:

- food‑grade materials

- easy‑to‑clean structure

- 安定したシール品質

- contamination prevention

Hygiene design directly affects food safety and shelf life.

H2

How to Choose a Packaging Machine for Food Industry

When selecting a food packaging machine, consider:

1. Food Type

Liquid, powder, granule, or solid.

2. Packaging Format

Bag, pouch, bottle, or carton.

3. Production Capacity

Daily and hourly output requirement.

4.自動化レベル

Semi‑automatic or fully automatic.

5.将来の拡張

Machines with modular design allow upgrades.

H2

Food Packaging Machine for Small vs Large Manufacturers

| ファクター | Small Manufacturer | Large Manufacturer |

|---|---|---|

| 出力 | 低~中 | 高い |

| オートメーション | セミオートマチック | 全自動 |

| 投資 | より低い | より高い |

| 柔軟性 | 高い | ミディアム |

H2

Common Mistakes in Choosing Food Packaging Machines

❌ ignoring hygiene standards

過度の自動化を選択する ❌ ❌ 過度の自動化を選択する

❌ underestimating future growth

❌ focusing only on initial price

Avoiding these mistakes improves long‑term efficiency.

H2

よくある質問

Q1: What is the most common food packaging machine?

Pouch and vertical packaging machines are widely used.

Q2: Are food packaging machines customizable?

Yes, many machines can be customized based on product and packaging needs.

Q3: How important is hygiene design?

Hygiene design is critical for food safety and regulatory compliance.

H2

結論

Packaging machines are essential for the food industry.

Choosing the right food packaging machine improves efficiency, safety, and product quality, ensuring long‑term success for food manufacturers.