1. What is a Packaging Machine?

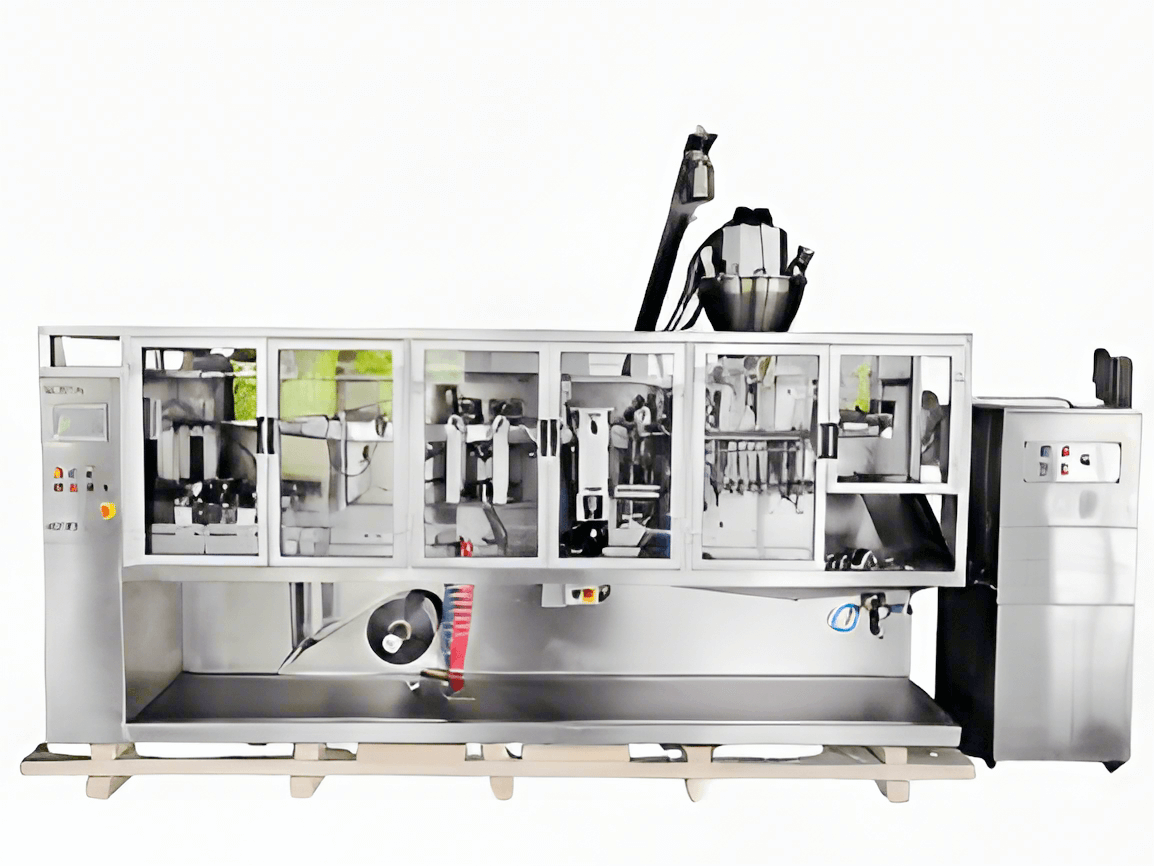

A 包装機 is an essential piece of equipment in modern manufacturing, designed to automate product packaging processes for industries such as food, pharmaceuticals, cosmetics, hardware, and electronics.

Depending on configuration, a packaging machine can perform tasks like filling, wrapping, sealing, labeling, cartoning, そして palletizing, ensuring consistent quality and higher productivity.

High-ranking keywords to consider:

- 包装機

- Automatic Packaging Solution

- Food Packaging Equipment

- Industrial Packing Machine

- Packaging Machinery for small business / large-scale production

2. Main Types of Packaging Machines

2.1 Vertical Form Fill Seal (VFFS) Machine

Ideal for packaging granular, powdered, or small solid products such as sugar, rice, coffee powder, and spices.

Pros: Compact footprint, cost-effective, versatile across different product types.

2.2 Horizontal Flow Wrapper

Used for bread, biscuits, chocolates, hardware parts, and other single-piece or grouped packaging.

Pros: High speed, perfect for continuous production lines.

2.3 Vacuum Packaging Machine

Suitable for meat products, seafood, and ready-to-eat meals requiring extended shelf life.

Pros: Excellent preservation, prevents oxidation and bacterial growth.

2.4 Shrink Wrapping Machine

Commonly used for beverage bottles, cartons, and multi-pack products.

Pros: Clean appearance, dust-proof, moisture-resistant.

2.5 Automatic Labeling Machine

Applies labels to bottles, cartons, or bags automatically, optimizing presentation and branding.

3. How to Choose the Right Packaging Machine?

When you search Google for “Buying Guide for Packaging Machine,” many high-ranking articles break the decision into categories. Based on industry experience, here are the key factors:

3.1 Product Characteristics

The machine choice depends on whether you are packaging パウダー, liquids, granules, あるいは solids.

3.2 Production Capacity

Decide how many packs per minute are required, and match machine speed to production goals.

3.3 Packaging Material Compatibility

Popular materials include plastic film, aluminum foil, そして composite film. Ensure your machine supports the chosen film type.

3.4 Level of Automation

Choose between semi-automatic そして fully-automatic solutions based on labor availability, cost, and efficiency requirements.

3.5 After-sales Service & Maintenance

Stable after-sales support and ease of maintenance are critical for long-term production stability.

4. Industry Trends in 2024

4.1 Smart Packaging Machines

Integration with IoT そして AI enables production monitoring, automatic fault diagnosis, and predictive maintenance.

4.2 Eco-friendly Packaging Solutions

Use biodegradable films or paper-based materials to comply with environmental regulations and appeal to eco-conscious consumers.

4.3 Flexible Manufacturing

Modular designs make it easy to switch between different product specifications, ideal for personalized and small-batch orders.

4.4 Growth in Cross-border E-commerce Packaging

The rise of e-commerce increases the demand for small item packaging machines, especially for international shipping.

5. Conclusion

Whether your business is in food processing, pharmaceuticals, daily chemicals, or hardware manufacturing, choosing the right 包装機 can directly impact your efficiency, product quality, and market competitiveness.

By following this 2024 packaging machine buying guide and keeping an eye on industry trends, you can make smarter investments and achieve sustainable growth.