はじめに

In industries such as cosmetics, pharmaceuticals, and food production, tube filling and sealing machines are essential for efficient, consistent, and hygienic packaging. Selecting the right equipment affects production speed, product quality, and overall return on investment (ROI).

This guide covers how these machines work, how to choose the right model, the impact of sealing methods on results, そして key maintenance practices—so you can make an informed purchase that supports your long-term production goals.

1. How Tube Filling and Sealing Machines Work

A tube filling and sealing machine automates the process of packaging products into soft tubes (plastic, laminated, aluminum-plastic composite, etc.).

Basic process overview:

- Tube feeding – Empty tubes are loaded into the machine’s tube holders.

- Tube orientation – The machine detects and aligns orientation marks to ensure correct print position.

- Filling process – Pre-measured volumes of material (e.g., cream, ointment, paste) are dispensed into the tube.

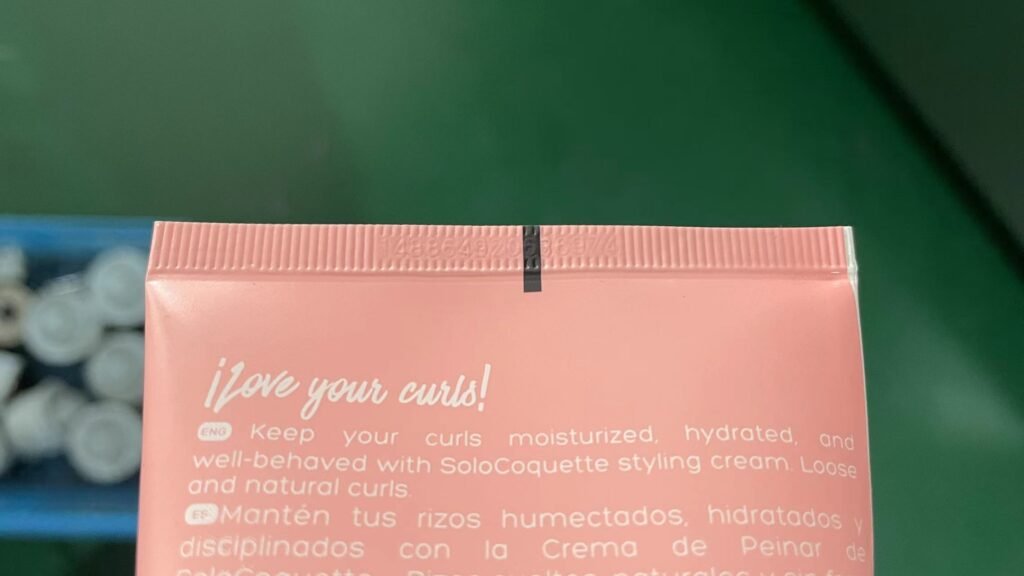

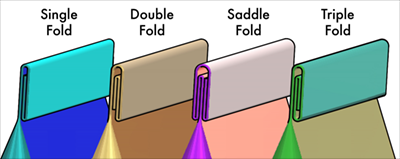

- シーリング – The open tube ends are sealed using heat, hot air, or ultrasonic methods.

- Trimming and coding – Excess material is trimmed, and the batch/date codes are applied.

- 出力 – Finished tubes are discharged to the conveyor for packing.

主なメリット

- Consistency – Uniform filling quantity and airtight sealing.

- 効率性 – Reduced labor costs, faster output.

- 衛生 – Controlled environment minimizes contamination.

2. How to Choose the Right Machine for Your Product

When selecting a tube filling and sealing machine, consider the following:

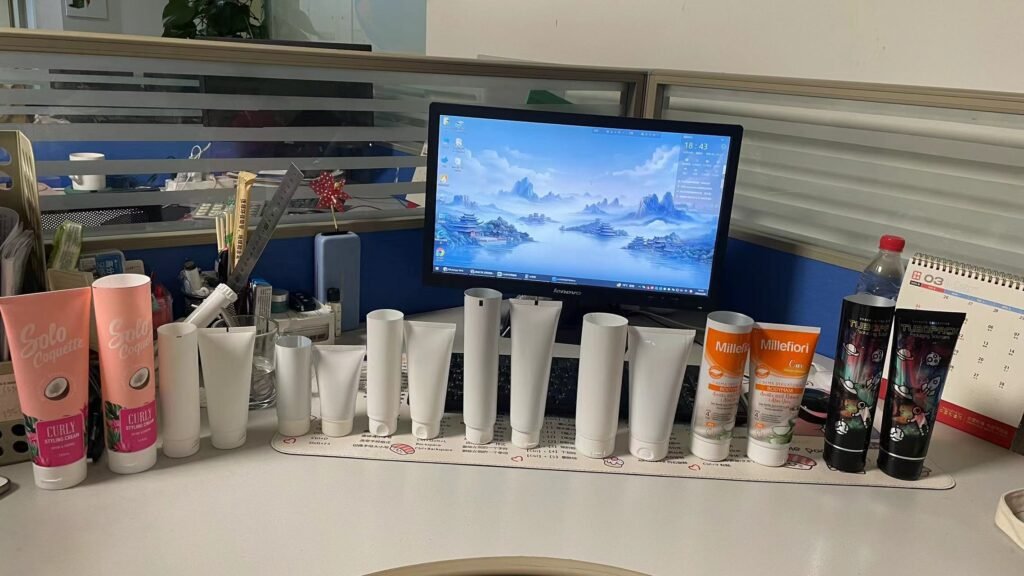

a) Tube Material Compatibility

- Plastic / Laminated Tubes – Common in cosmetics; require hot air sealing for neat and durable results.

- Aluminum Tubes – Often used for pharmaceuticals; require metal crimping methods.

b) Product Viscosity

- Low viscosity (serums, gels) → requires precision filling systems to avoid leakage.

- High viscosity (toothpaste, ointment) → needs strong piston pumps or rotary valves.

c) Production Volume

- セミオートマチック: Suitable for small batches; lower cost but slower speed.

- Automatic: Ideal for high production lines; higher initial investment but better ROI.

d) Tube Size Range

Choose machines that can handle your required diameter and length, or opt for customizable change parts.

3. Sealing Methods and Their Impact

The sealing technique directly affects the tube’s durability, shelf life, and appearance.

Hot Air Sealing

- Best for plastic & laminated tubes.

- メリット: Strong, neat seam, high aesthetics.

- Limitations: Requires well-controlled heat to avoid damage.

Ultrasonic Sealing

- Best for heat-sensitive products or materials.

- メリット: Fast sealing without preheating, minimal thermal impact.

- Limitations: Higher equipment cost, specialized parts.

Metal Crimping

- Best for aluminum tubes.

- メリット: Airtight, tamper-proof seal.

- Limitations: Only suitable for metal tubes.

4. Daily Maintenance & Troubleshooting

Regular maintenance keeps machines running smoothly and prevents downtime.

Daily Maintenance Tips:

- Wipe and clean filling nozzles after each batch.

- Check heat sealing components for residue buildup.

- Lubricate moving parts as per manufacturer guidelines.

- Inspect sensors for correct alignment.

Common Troubleshooting:

- Inconsistent fill weight: Check pump calibration, clean valves.

- Poor sealing: Verify temperature/ultrasonic settings and sealing jaws alignment.

- Tube misalignment: Adjust orientation sensors or mechanical stops.

- Material leakage: Inspect nozzle seals and replace worn gaskets.

5. Conclusion & Call to Action

正しい選択 tube filling and sealing machine requires analyzing your product characteristics, production needs, and packaging goals.

Proper sealing not only ensures product integrity but also enhances brand image. Once installed, regular maintenance is the key to long-term efficiency and minimal downtime.

Looking to optimize your packaging line?

お問い合わせ for a free consultation and equipment recommendation tailored to your production requirements.