Section 1: What is Horizontal Form Fill Seal (HFFS)?

Horizontal Form Fill Seal (HFFS) is an automated packaging process where a machine forms, fills, and seals flexible pouches in a horizontal orientation. The machine unwinds rollstock film, forms the pouch (including gussets and spout areas if required), doses product via multi-head weighers or flow meters, and seals the pouch with precise heat and pressure. HFFS systems are ideal for doypack pouches, standing pouches, and spouted pouches used for sauces, beverages, gels, powders, granules, and snacks.

Key advantages of HFFS:

– Premium pouch formats: doypack pouch, stand up pouch, spout pouch

– High speed with excellent repeatability and seal integrity

– Lower packaging material waste, consistent pouch dimensions

– Integration with CIP-rated liquid fillers and multi-head weighers

– Superior brand presentation with zipper, spout, and laser scoring options

Section 2: Types of Form Fill Seal Machines Form fill seal machines come in several configurations to match product characteristics and throughput targets:

- Horizontal Form Fill Seal (HFFS):

- Best for premium stand up pouches and doypack pouch formats

- Supports spout pouch packaging machine modules for liquids

- Excellent for products needing wide seal areas and complex features (zippers, spouts, reclose)

- Vertical Form Fill Seal (VFFS):

- Film is formed into a vertical tube; ideal for pillow bags, sachets, and some gusseted bags

- Often used for powders, granules, snacks

- Typically higher speed for simple bag styles, lower material utilization for premium pouches

- Automatic Rotary Filling Standing Pouch Machine:

- Indexing rotary stations for premade standing pouch packaging machine applications

- Great for lower to medium speeds using premade pouches with high flexibility

- Fast changeovers and excellent format variety

- Doypack Automatic Packing Machine:

- Specialized for doypack pouch styles; can be rollstock (HFFS) or premade (rotary)

- Automates opening, filling, sealing, code printing, and inspection

Section 3: HFFS vs VFFS – What’s the Difference? While both are FFS technologies, HFFS and VFFS serve distinct needs:

- Orientation and format:

- HFFS: Horizontal web handling; excels at doypack pouch and stand up pouch packing machine applications

- VFFS: Vertical web forming; best for pillow bags, simple gusset bags

- Product suitability:

- HFFS: Liquids, viscous products, powders and granules needing premium shelf display; integrates spout pouch packaging machine modules

- VFFS: Free-flowing powders, snacks, rice, sugar—high speeds for basic formats

- Features and aesthetics:

- HFFS: Zippers, spouts, laser-tear, shaped pouches, reinforced corners; superior print registration and seal symmetry

- VFFS: Simpler configurations, limited advanced features compared to HFFS

- Throughput and cost:

- VFFS often delivers higher speeds for basic bags with lower initial machine cost

- HFFS delivers premium pouch quality and brand differentiation with higher machine investment but better retail impact and consumer convenience

Section 4: Stand Up Pouch and Doypack Solutions To meet modern retail demands, brands are shifting from rigid containers to flexible pouches. HFFS systems enable:

- Standup pouch filling machine capabilities for powders, granules, and liquids

- Doypack packing machine automatic operation from rollstock with reduced labor

- Integration with spout insertion for spout pouch packaging machine lines

- Quality control modules: inline leak detection, vision inspection, weight checking

- Quick changeover between formats and sizes to support SKU variety

Section 5: Cost Insights – Bosch Packing Machine and Market Ranges The cost of “Bosch packing machine” (now branded Syntegon following Bosch Packaging Technology’s transition) varies by model and configuration. In general:

- VFFS entry-level systems: typically lower cost for simple pillow bags

- HFFS systems for doypack/stand up pouches: higher investment due to advanced forming, sealing, and special features (zippers, spouts, shape forming)

- Automatic rotary filling standing pouch machine (premade pouch): mid-range to high, depending on stations, automation, and integrations

Indicative market ranges (for reference only; actual pricing depends on options, speed, and region):

- VFFS basic: tens of thousands USD+

- 롤스택의 HFFS 도이팩: 5달러 중반에서 6달러 후반대 이상

- 로터리 프리메이드 스탠드업 파우치 라인: 5~6만 달러 중반 이상

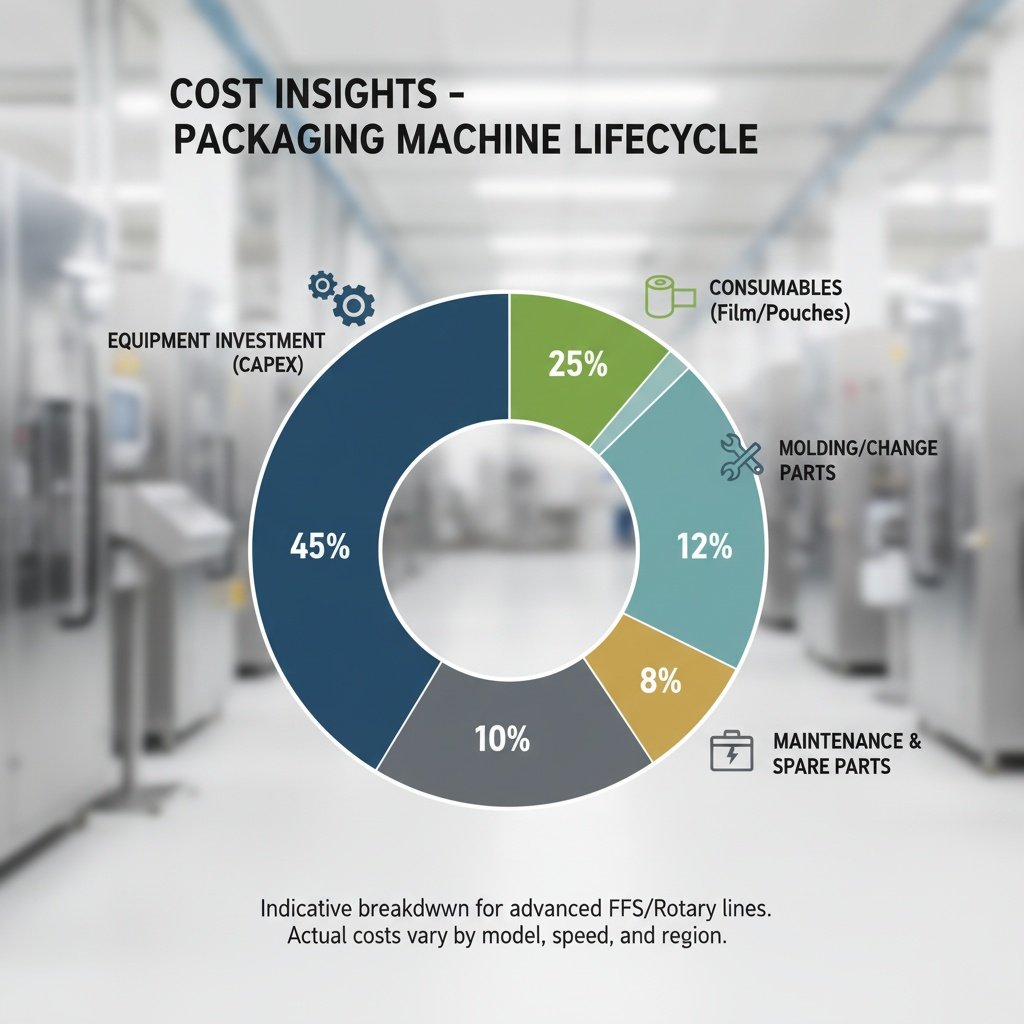

비용을 비교할 때는 다음 사항을 고려하세요:

- 처리량(파우치/분)

- 전환 시간 및 형식 유연성

- 필름 대 사전 제작 파우치 단위당 비용

- 스파우트 삽입, 지퍼 어플리케이터 및 제품 도징과 통합

- 판매 후 지원, 예비 부품 가용성 및 에너지 소비량

섹션 6: 올바른 HFFS 머신을 선택하는 방법

- 파우치 형식 정의: 도이팩 파우치, 스탠드업 파우치, 스파우트 파우치

- 제품 지정: 액체 대 분말, 점도, 충전 정확도 요구 사항

- 목표 속도: 생산량과 제품 취급 및 품질 관리의 균형 유지

- 필름 및 지속 가능성: 재활용 가능한 단일 소재, 더 얇은 게이지, 간편한 개봉 기능

- 라인 통합: 업스트림 믹서/계량기, 다운스트림 케이스 포장, 코딩 및 검사

- 서비스 및 교육: 원격 진단, 현지 서비스 네트워크, 예비 부품 물류