In modern packaging lines, the automatic cartoning machine plays a vital role in improving efficiency, consistency, and product presentation. Whether in the pharmaceutical, cosmetic, food, or daily chemical industries, cartoning solutions have become essential equipment for manufacturers aiming to scale production while maintaining high quality standards.

This article provides a comprehensive overview of auto cartoning machines, covering working principles, technical parameters, selection guidance, industry applications, and maintenance tips. It is designed to help buyers, engineers, and procurement managers make informed decisions while improving search visibility for key cartoning machine-related terms.

1.What Is a Cartoning Machine Used For?

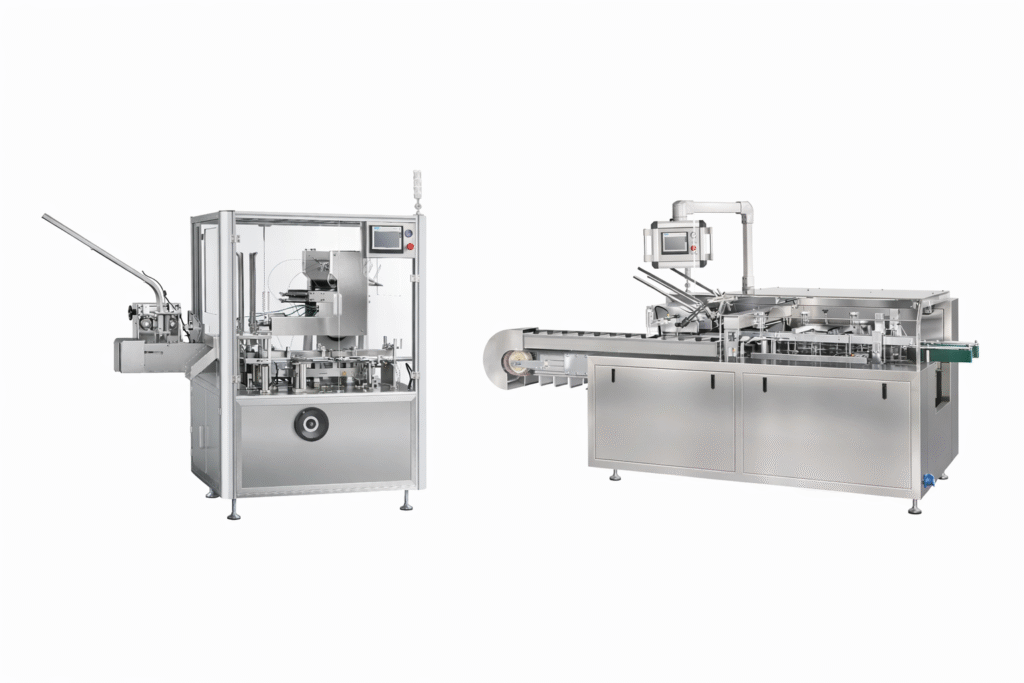

A cartoning machine is an automated packaging system used to erect cartons, insert products, and close boxes in a continuous process. It is widely applied to package items such as blister packs, bottles, tubes, sachets, inner packs, and finger sticks into pre-folded cartons.

A cartoning machine fully automatic typically integrates carton feeding, product insertion, leaflet insertion, carton closing, and output conveying into one streamlined system. Compared with manual or semi-automatic solutions, it significantly reduces labor costs and improves packaging consistency.

Common Functions of a Cartoner

Automatic carton erection

Product and leaflet insertion

Carton closing (tuck-in or glue sealing)

Quality inspection and rejection

A semi-automatic cartoning machine is often used for lower-speed lines or limited budgets, requiring partial manual loading while still improving efficiency over fully manual packing.

2.What Does a Cartoner Do in Different Industries?

Cartoners are highly versatile and can be customized for specific industries:

Cartoning Machine in the Pharmaceutical Industry

A cartoning machine pharmaceutical industry solution must meet GMP standards and ensure precise handling of sensitive products. Typical applications include:

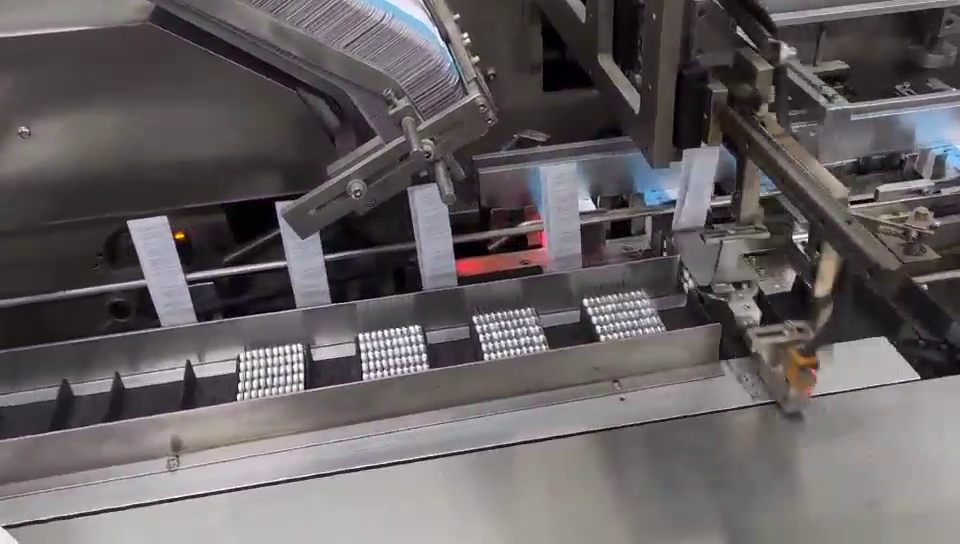

Automatic blister cartoning machine for tablets and capsules

Cartoning machine for bottle packaging of syrups and liquids

Cartoning machine for inner pack with leaflets

High accuracy, dust protection, and easy cleaning are critical requirements in this sector.

Cartoning Machine for Cosmetics

A cartoning machine cosmetics application focuses on appearance and gentle handling. It is commonly used for:

Cream tubes

Skincare bottles

Perfume packaging

Customization options such as hot-melt glue sealing and decorative carton handling are often required.

Food and Specialty Applications

Food packaging also benefits from automated cartoning, such as:

Carton machines pizza for frozen or takeaway pizza boxes

Cartoning machine for finger stick products like honey sticks or energy gels

3.How Does a Fully Automatic Cartoning Machine Work?

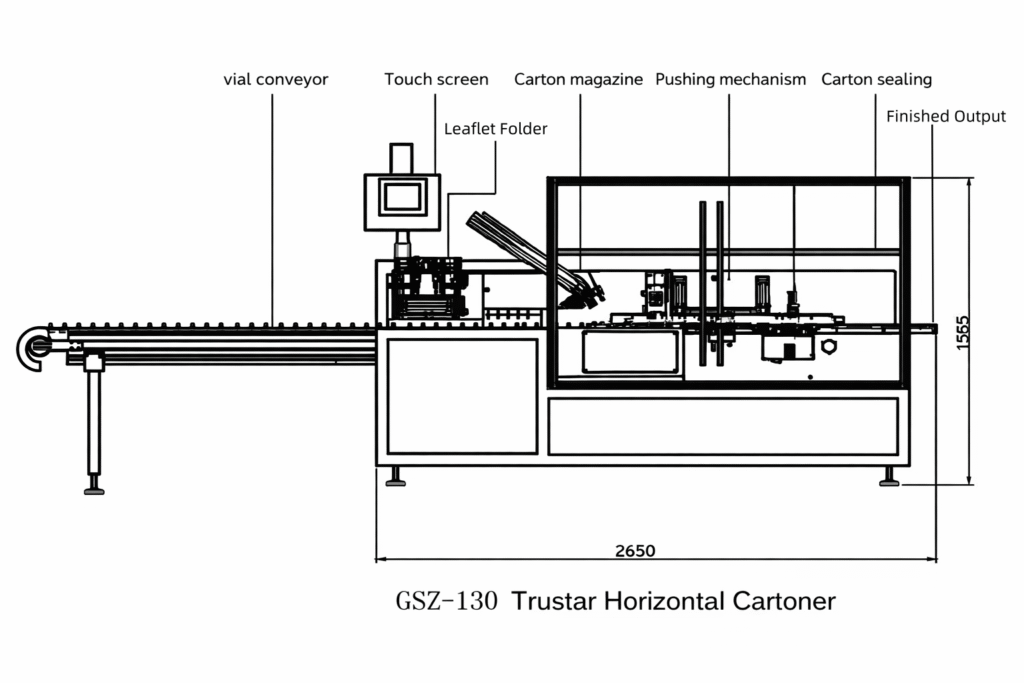

Understanding the cartoning machine working principle is essential for technical buyers and engineers.

A typical auto cartoning machine operates in the following steps:

Carton Feeding – Flat cartons are automatically picked and erected

Product Feeding – Products such as blisters, bottles, or inner packs are synchronized

Insertion Process – Products and leaflets are inserted using pushers or robotic arms

Carton Closing – Cartons are sealed via tuck flaps or glue

Output & Inspection – Finished cartons are conveyed out and inspected

Some systems integrate a carton erector machine upstream, especially in high-speed lines, to ensure smooth carton supply.

A cam cartoner uses mechanical cam-driven systems, offering high stability and precise timing, making it ideal for pharmaceutical and high-speed applications.

4.Key Technical Parameters of a Cartoning Machine

When evaluating equipment, buyers should focus on cartoning machine technical parameters, including:

Production speed: cartons per minute

Carton size range: length, width, height

Product compatibility: blister, bottle, inner pack, finger stick

Control system: PLC + HMI interface

Power supply & air consumption

Machine dimensions & weight

High-end systems also support data tracking and can be integrated with upstream and downstream equipment.

5.How to Choose the Right Cartoning Machine?

What Factors Affect the Price of a Cartoning Machine?

The price of an automatic cartoning machine depends on:

Level of automation (semi-automatic vs fully automatic)

Production speed requirements

Product complexity

Customization level

Brand and component selection

For startups or small factories, a semi-automatic cartoning machine may be a cost-effective entry solution. Large-scale manufacturers often invest in fully automatic systems for long-term ROI.

Selection Tips for Buyers

Define product type clearly (bottle, blister, inner pack)

Estimate future capacity expansion

Check availability of carton machine spare parts

Request a cartoning machine video to verify real performance

6.How to Maintain a Cartoning Machine for Long-Term Use?

Proper cartoning machine maintenance ensures long service life and stable operation.

Daily Maintenance

Clean dust and carton debris

Check sensors and safety guards

Periodic Maintenance

Lubricate cams and moving parts

Inspect belts, chains, and pushers

Replace worn carton machine spare parts promptly

Scheduled maintenance reduces downtime and protects production efficiency, especially in pharmaceutical and cosmetic applications.

7.Factory Strength and Extended Solutions

As an experienced manufacturer and exporter of cartoning equipment, we provide:

Customized cartoning machine for bottle, blister, and inner pack

Integration with carton erector machine and end-of-line systems

Technical support, spare parts supply, and remote troubleshooting

Our machines are designed for global markets, with CE-compliant standards and flexible configurations for different industries.

Conclusie

From understanding what a cartoner does to selecting the right cartoning machine fully automatic solution, investing in the correct equipment can dramatically improve packaging efficiency and product quality. Whether you are in pharmaceuticals, cosmetics, or food packaging, a reliable automatic blister cartoning machine or customized auto cartoning system is a key asset for scalable production.

If you are looking for a professional and cost-effective cartoning solution, feel free to contact us for technical consultation and tailored recommendations.