Inleiding

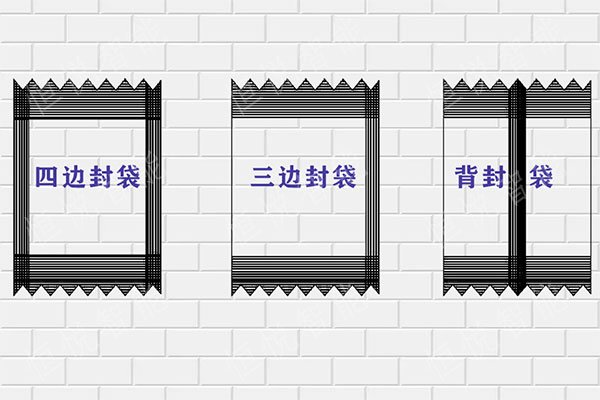

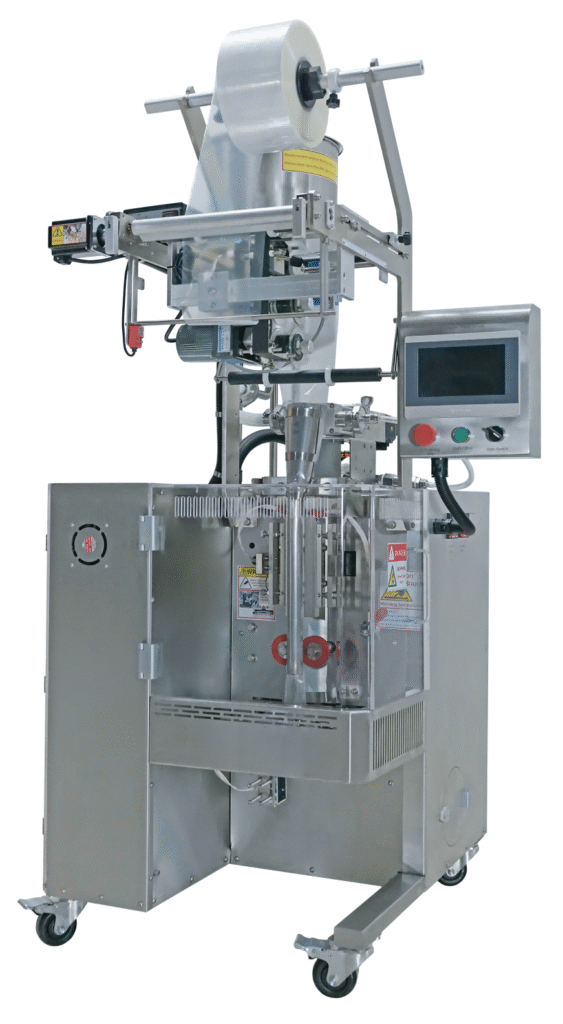

In today’s fast-paced packaging industry, efficiency, flexibility, and hygiene in operations are essential. Vertical Form Fill Seal (VFFS) machines — also called vertical pouch packaging machines — have become a popular choice for businesses packing powders, granules, and liquids. Whether you require four-side sealing, three-side sealing, of back sealing, the versatility of VFFS allows adaptation to various product types and packaging styles, making it a reliable solution for different industries.

What is the Working Principle of a Vertical Form Fill Seal Machine?

A vertical form fill seal packaging machine operates in a continuous, fully automated process, which typically includes:

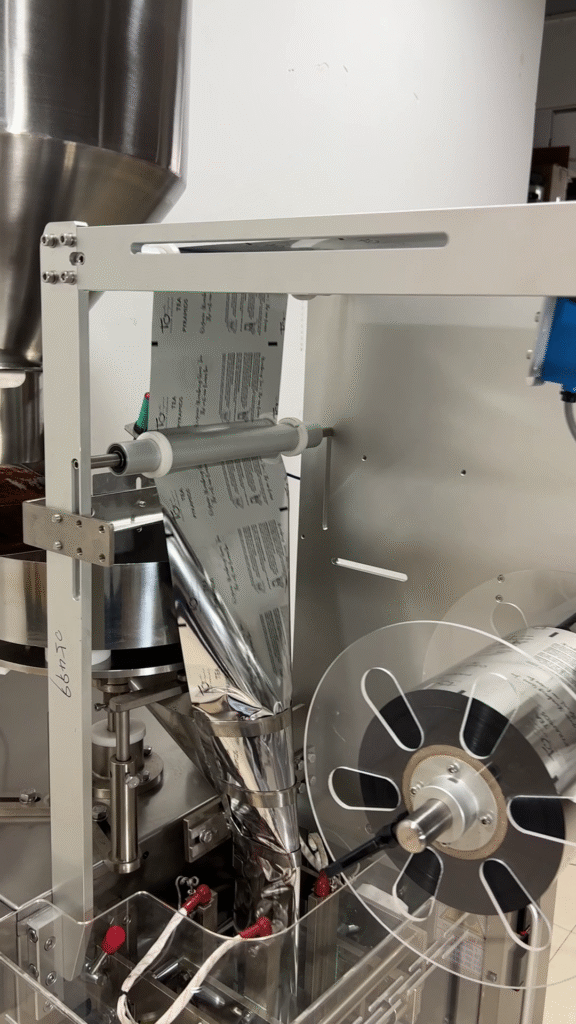

- Film Unwinding– Packaging film rolls are pulled into the machine.

- Bag Forming– Film is shaped into a vertical tube using a forming collar.

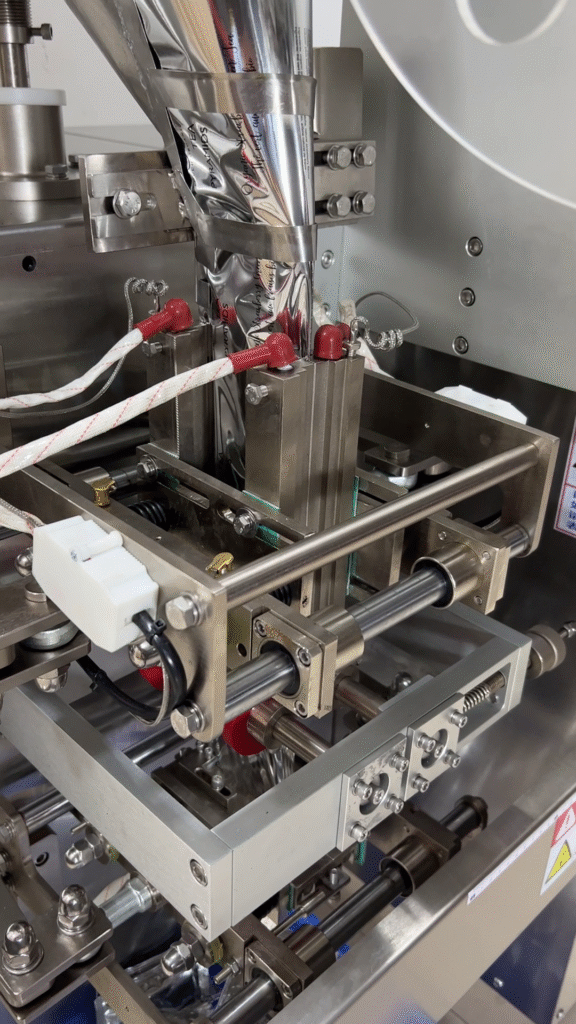

- Afdichting– The machine seals the film vertically to create the pouch.

- Vullen– Depending on the product type, filling systems can include:

- Screw Auger Filler – Ideal for powders such as flour, coffee, or spice mixes.

- Cup Filler – Best for granules such as nuts, beans, or candy.

- Pump Filler – Suitable for liquids and pastes like sauces, oils, or creams.

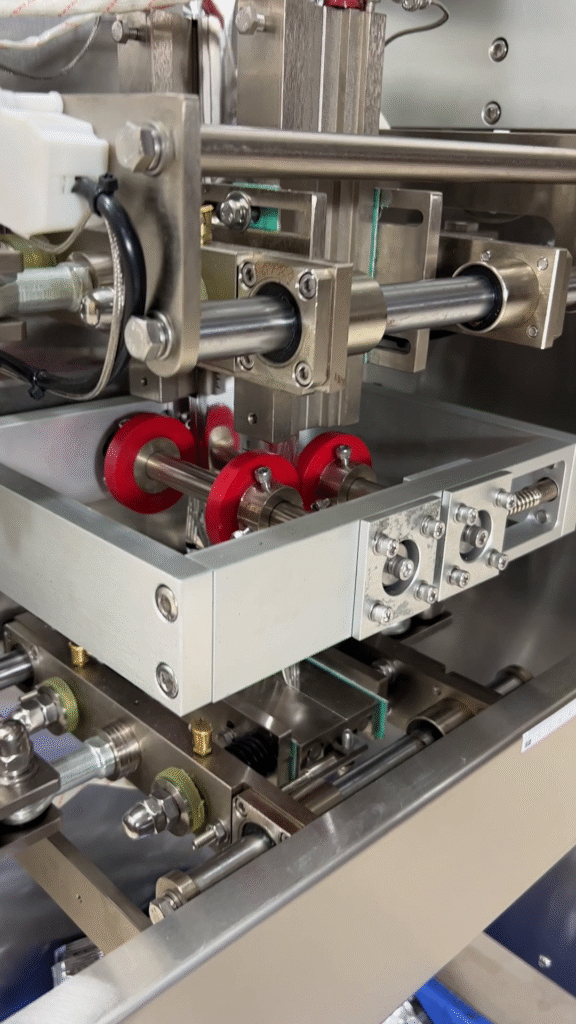

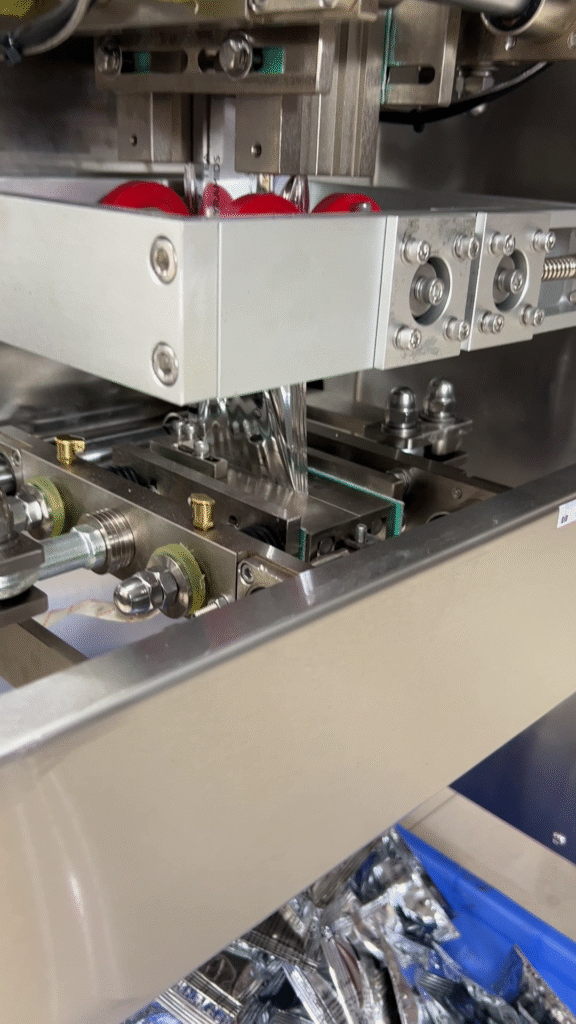

- Horizontal Sealing and Cutting– Top and bottom seals are made, and pouches are cut to size.

This continuous process ensures consistent pouch quality and high-speed production.

Different Types of Form Fill Seal Machines

Form fill seal machines are categorized mainly into two types:

1.Vertical Form Fill Seal Machines (VFFS)

- Work vertically with the film moving downwards.

- Ideal for free-flowing products and space-saving factory layouts.

- Commonly used for food, pharmaceuticals, and chemicals.

2. Horizontal Form Fill Seal Machines (HFFS)

- Operate horizontally.

- Better for products that require careful handling or for larger packages.

Difference between HFFS and VFFS:

- HFFSpouches are formed and filled along a horizontal axis, providing more control for fragile products.

- VFFSis more compact and faster for high-volume small to medium pouch production.

Applications of VFFS Packaging Machines

De form fill seal packaging machine suits various industries:

- Food industry– Coffee powder, snacks, frozen goods, sauces.

- Pharmaceutical industry– Medical powder, tablets, liquids.

- Chemical industry– Industrial granules, fertilizers, detergents.

Its adaptability comes from the ability to choose different sealing options — four-side seal, three-side seal, of back seal — and customized filling mechanisms for powder, granule, and liquid products.

Advantages of Vertical Pouch Filling and Sealing Machines

- High efficiencyand speed suitable for mass production.

- Flexible packaging stylesfor various market needs.

- Space-saving designcompared to horizontal systems.

- Easy integrationwith weighing, labeling, and coding systems.

- Consistent sealing qualityensuring product freshness and safety.

Conclusie

De vertical form fill seal machine is a versatile and efficient solution for modern packaging needs. By choosing the right filling system and sealing format, businesses can achieve optimal production speed, packaging quality, and customer satisfaction. Whether you are packing powders with a powder filling form fill and seal pouch machine, or liquids with a form fill seal machine pouch liquid, investing in a reliable VFFS machine can transform your packaging process.