In the world of manufacturing, few pieces of equipment are as critical and versatile as the pill press. Whether you are in the pharmaceutical industry, producing dietary supplements, or manufacturing industrial chemicals, turning powder into uniform, solid shapes is a fundamental process.

As a manufacturer with over 20 years of experience in this field, we have witnessed the evolution of the pill press machine. Today, we are diving deep into what these machines are actually for, how they work, and why choosing the right tablet press is crucial for your business success.

What is a Pill Press Machine?

At its core, a pill pressing machine (also technically known as a tablet press) is a mechanical device that compresses powder into tablets of uniform size and weight.

The principle sounds simple: fill a die with granules or powder and compress it using punches. However, modern pill presser machines are marvels of engineering. They ensure that every single tablet contains the exact amount of active ingredients, is hard enough to withstand packaging, yet dissolves perfectly when consumed.

What Are Pill Presses Used For? 4 Key Industries

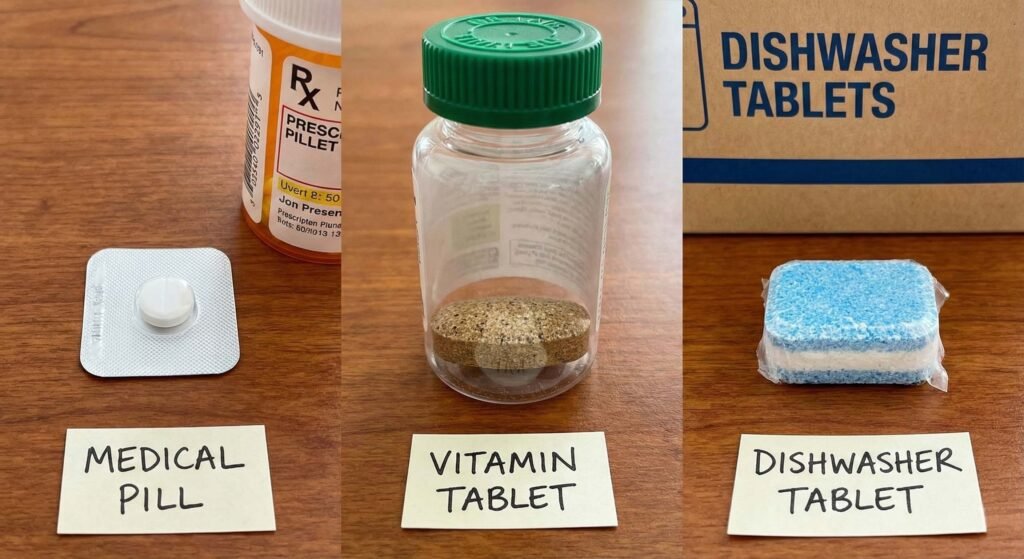

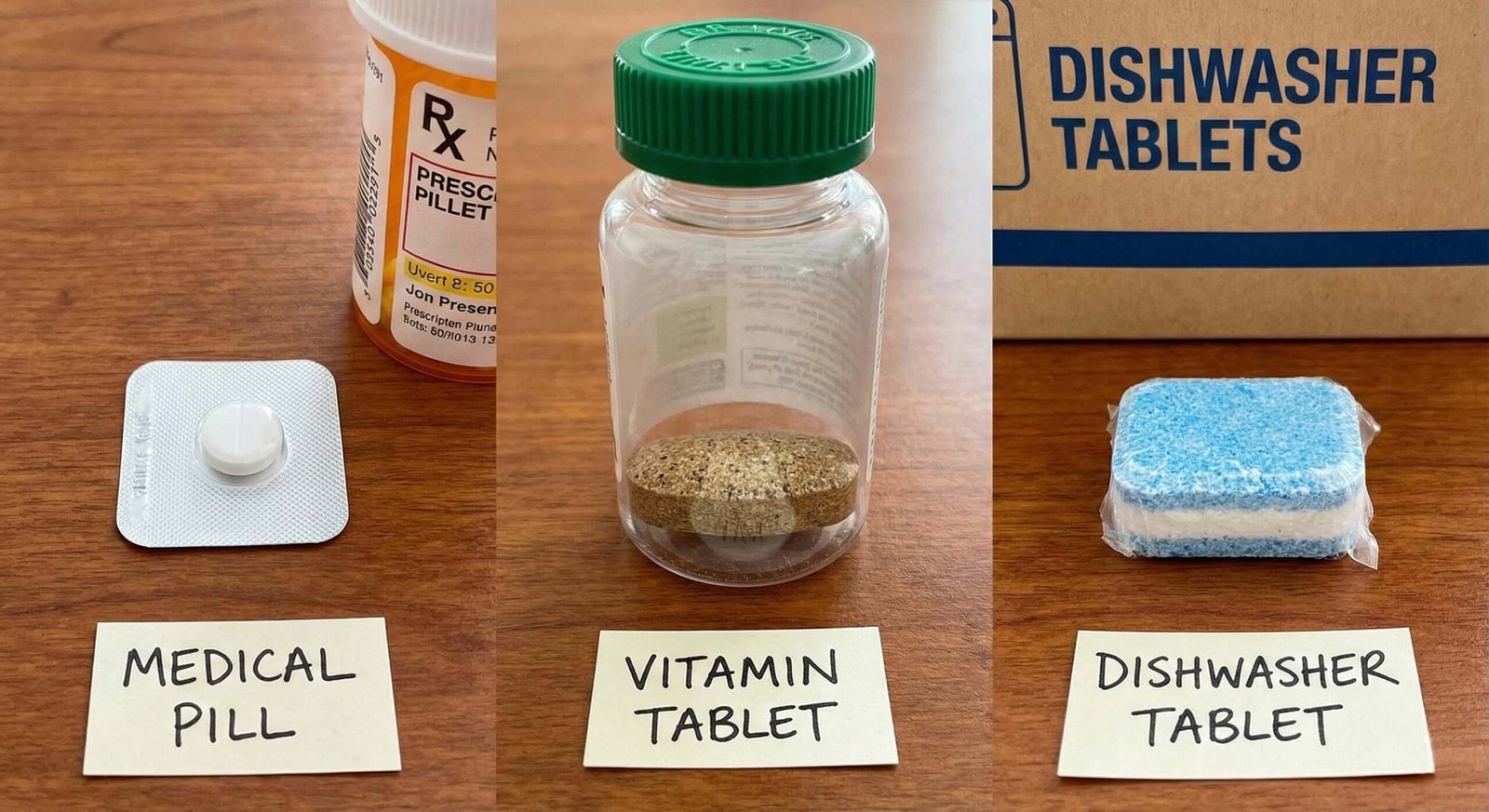

When people ask “What are pill presses for?”, they often assume it’s strictly for medicine. While that is a huge part of it, the applications of a pill presser extend far beyond the pharmacy.

1. Pharmaceutical Manufacturing

This is the most obvious use. In this sector, precision is not just a luxury; it’s a legal requirement. A pill tablet press in the pharma industry must adhere to strict GMP (Good Manufacturing Practice) standards. They are used to create:

- Immediate-release tablets

- Chewable medications

- Controlled-release pills

2. Nutraceuticals and Dietary Supplements

The vitamin and supplement market is booming. From multivitamins to herbal extracts, a pill press machine allows manufacturers to create custom shapes and sizes that appeal to health-conscious consumers. Efficiency is key here to keep up with high market demand.

3. Confectionery and Candy

Did you know that breath mints and pressed candies are made using the same technology? A pill press can be outfitted with custom tooling to stamp logos or fun shapes onto candy, making it a vital tool for the food industry.

4. Chemical and Industrial Applications

Beyond consumption, pill presser machines are used to create:

- Dishwasher detergent tabs

- Water purification tablets

- Catalyst pellets for chemical reactions

- Fertilizer tablets

Types of Machines: Single Punch vs. Rotary

To understand what these machines do, you must understand the two main categories.

Single Punch Tablet Press

Often called an eccentric press, this is the simplest form of a pill presser. It uses a single set of station tooling (die and punches).

- Geschikt voor: R&D, small batches, laboratory testing, and compounding pharmacies.

- Pros: Easy to operate, small footprint, and cost-effective.

Rotary Tablet Press

For mass production, the rotary tablet press is the industry standard. It involves multiple tooling stations rotating on a turret.

- Geschikt voor: Large-scale manufacturing (thousands to millions of tablets per hour).

- Pros: High speed, high output, and superior weight control.

[Insert Image Here] Image Description: An infographic or a split photo showing a Single Punch Press on the left and a large Rotary Press on the right. Alt Text: Comparison between single punch pill presser and rotary tablet press.

Why Quality Matters in a Pill Pressing Machine

Not all machines are created equal. Since we have been manufacturing pill press machines for over two decades, we know that the difference between a profitable production line and a failed one often lies in the equipment.

Een hoge kwaliteit tablet press ensures:

- Consistentie: Every pill has the exact same weight and density.

- Durability: The machine can run for long hours without breaking down.

- Safety: Modern sensors and enclosed designs protect operators.

- Versatility: The ability to switch molds for different shapes and sizes easily.

If you are looking for a reliable pill press, avoid cheap, generic options that lack support. Your production line deserves equipment backed by engineering expertise.

Conclusie

So, what are pill presses for? They are the heartbeat of mass production for industries ranging from life-saving medicines to everyday household items. Whether you need a compact pill presser for a lab or a high-speed rotary pill press machine for a factory, the technology is essential for efficiency.

Klaar om je productielijn te upgraden? With 20+ years of manufacturing excellence, we provide tablet press solutions that combine precision, durability, and value.

[Contact Us Today] to discuss which machine fits your production needs.