If your rotary tablet press can’t hit the advertised speed, it’s rarely a single fault. Nameplate speed assumes ideal granules, small tablets, ample dwell time, perfect tooling, and a clean, well‑tuned line. In real production, small deviations compound into a speed ceiling. Below is a practical, engineering-led breakdown of the root causes, how to diagnose them quickly, and how GZPK-51 addresses them.

What the Nameplate Speed Assumes

- Free‑flowing granules (low cohesion, minimal fines, stable bulk density)

- Fast and consistent die fill at high RPM

- Adequate dwell time to achieve target hardness without overpressure

- Tight tooling tolerances with minimal wear and perfect alignment

- Smooth upstream feeding and minimal downstream back‑pressure

- Stable environment (humidity, temperature) and clean, non‑sticky formulation

Twelve Engineering Reasons Your Press Runs Below Spec

- Granule flowability is marginal

- Poor flow, high fines, or humidity cause slow/uneven die fill at high RPM, forcing you to reduce speed to control weight variation.

- Die fill time is insufficient

- Larger fill depths, low density powders, or high paddle restrictions require more residence time under the feeder; speed must drop.

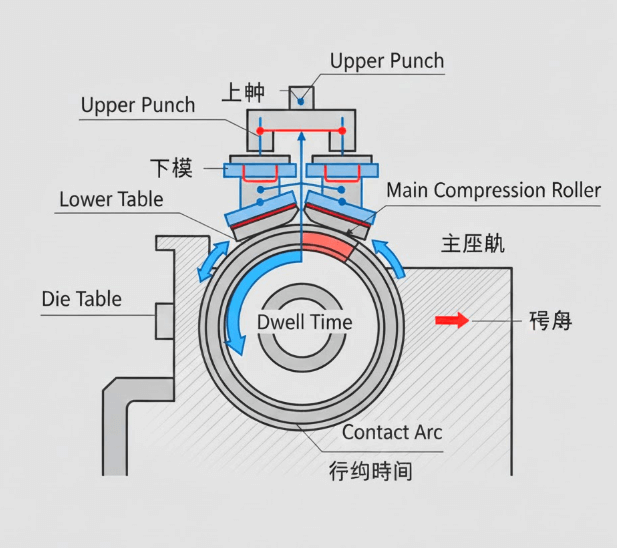

- Dwell time vs. hardness conflict

- Hardness targets for difficult actives or high-load formulas demand longer dwell; you keep pressure below limits, so you slow the turret.

- Precompression and main compression imbalance

- Poor precompression transitions cause capping or lamination at high RPM; operators slow down to stay within rejection limits.

- Weight-control feedback lag

- Aggressive speed with slow feedback filtering causes weight oscillation; the control loop stabilizes only at lower RPM.

- Tooling wear or tolerance drift

- Worn punches/dies (or out-of-spec bores) increase friction, heat, and sticking risk; speed reductions prevent damage and scrap.

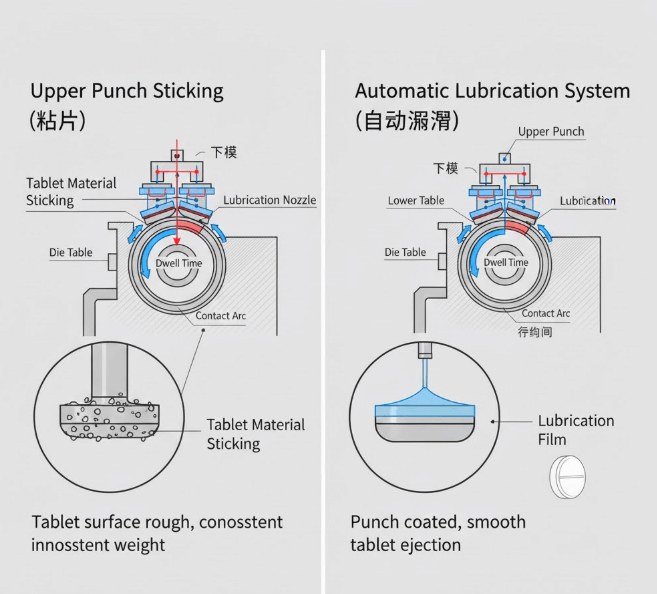

- Sticking, picking, and inadequate lubrication

- Adhesive actives or low-lube blends stick at high rates; without optimized lubrication, you must run slower to avoid shutdowns.

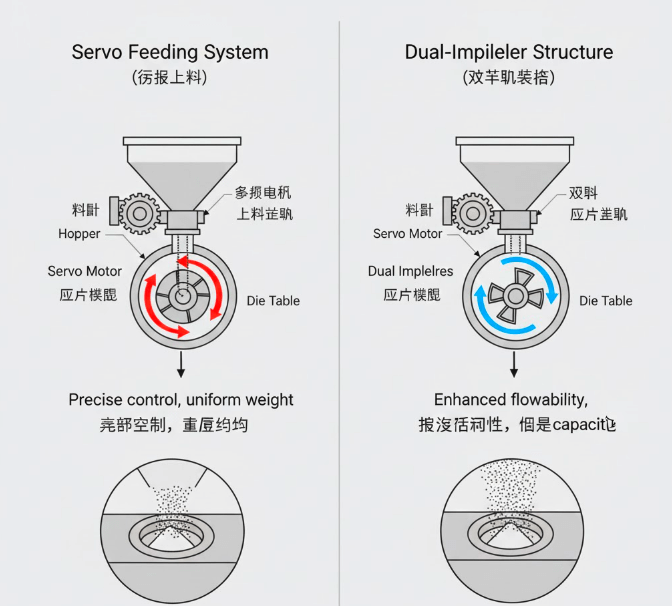

- Feeder tuning and hopper starvation

- Incorrect servo feeder speed/paddle angle or segregating blends lead to episodic underfill; speed drops to keep weight CV in spec.

- Turret balance and mechanical condition

- Misalignment of compression rollers, worn bearings, or vibration triggers alarms and variability; slowing masks the mechanical issue.

- Line integration back‑pressure

- Deduster, metal detector, or vacuum extraction impose resistance; tablet discharge chokes at high speed, forcing RPM cuts.

- OPC/PLC safety and quality limits

- Remote monitoring thresholds or torque/pressure caps prevent overshoot; when limits are hit, the system throttles speed.

- Environmental variability

- Moisture spikes, temperature drift, or electrostatic charge change flow/compaction; speed must follow the worst condition.

Quick Diagnostic Checklist (Run This Before Blaming the Press)

- Flowability: Measure angle of repose, Carr index, and funnel flow rate; screen fines and control humidity.

- Bulk density and fill depth: Confirm target fill at speed; adjust feeder paddle angle and clearance.

- Dwell pressure map: Record hardness vs. RPM vs. main/precompression settings to find the real dwell constraint.

- Tooling audit: Check punch head and tip wear, die bore roundness, alignment; replace out-of-tolerance sets.

- Lubrication: Verify lube level, distribution, and auto-lube cycle; consider punch tip coatings for sticky APIs.

- Feedback tuning: Optimize weight control filters and sampling windows to stabilize at higher RPM.

- Mechanical health: Inspect rollers, bearings, turret runout, vibration; correct before speed trials.

- Line choke points: Validate deduster/metal detector capacity at target throughput; adjust vacuum and discharge angles.

- OPC limits: Review alarm thresholds, torque/pressure caps, and speed ceilings in the control system.

How GZPK-51 Tackles These Constraints

- Dual compression rollers: More available dwell at higher RPM, achieving hardness without exceeding pressure caps.

- Servo feeding: Precisely tunes paddle speed and angle for consistent die fill and lower weight CV at speed.

- High tooling precision: Better concentricity reduces friction and heat, enabling stable high-speed compression.

- Automated lubrication: Consistent film on punches/dies reduces sticking/picking and thermal rise at high throughput.

- Anti-sticking design: Surface finishes and airflow management lessen adhesion, cutting unplanned stops.

- OPC remote monitoring: Real-time torque/pressure/weight dashboards let you trim settings before variability escalates.

- Integration performance: Designed to match high-capacity dedusters and detectors to avoid discharge bottlenecks.

Will Speed and Pressure Both Be Met?

- Yes—within a defined product window. We qualify speed with target hardness, thickness, and weight CV using your granules. The dual-roller design and servo feeding let you keep hardness while maintaining die-fill quality at higher RPM.

Can You Pass FAT/SAT?

- We run FAT with your specified formulation or a validated surrogate, with acceptance limits on speed, weight CV, hardness, and reject rate. SAT repeats the protocol on site with your utilities and line equipment to confirm throughput at scale.

Tooling Life and Compatibility

- With proper lubrication, alignment, and hardness targeting, tooling life meets industry norms. We provide recommended coatings for sticky APIs and tolerance maps to protect punch tips at high speed.

Will It Work With Your Granules?

- We assess flow, density, compressibility index, and moisture. If granules are marginal, we advise spheronization, dry‑granulation tweaks, fines reduction, or lubrication strategy changes to unlock speed without sacrificing GMP limits.

Market Reality: Speed Isn’t Everything

- Under rising GMP scrutiny, stability and consistency matter more than raw RPM. Data tracking via OPC, weight CV control, and automated lubrication reduce downtime and batch risk—often delivering higher net throughput than chasing nameplate speed alone.

Action Plan to Close the Speed Gap

- Run the diagnostic checklist and capture data at incremental RPM steps.

- Tune servo feeder and pre/main compression balance; update OPC limits.

- Replace worn tooling and verify lubrication cycles.

- Align downstream capacity (deduster, detector, vacuum) with target throughput.

- If granule flow is borderline, adjust formulation or granulation to improve fill and compaction behavior.