In the global food and beverage market, the demand for quick, efficient, and hygienic packaging solutions is growing rapidly. Whether you run a specialty coffee brand, a cocoa powder manufacturing plant, or a health supplement company, packaging plays a vital role in product preservation, branding, and customer satisfaction.

The Automatic Powder Cocoa Coffee Food Packaging Machine is an advanced piece of equipment specifically designed for accurately measuring, filling, and sealing powdered products into high-quality packages. This article will give you a complete understanding of its functions, benefits, applications, and tips for choosing the right machine for your business.

What is an Automatic Powder Packaging Machine?

An automatic powder packaging machine is a device that integrates weighing, filling, sealing, and cutting into one automated process. It is suitable for a wide range of powders, including:

- Coffee powder / ground coffee

- Cocoa powder

- Milk powder

- Protein powder

- Spices and seasonings

- Flour, sugar, and other food-grade powders

Its technology ensures that every package is consistent in weight and sealing quality, preventing contamination and enhancing shelf life.

Why Automation is the Future of Powder Packaging

Manual packaging is time-consuming, inconsistent, and prone to contamination. Automation solves these problems by:

- Boosting Productivity – Pack more units in less time.

- Ensuring Accuracy – Avoid human error in measuring powders.

- Improving Hygiene – Reduce direct human contact with food products.

- Saving Labor Costs – Fewer workers needed for the same output.

In competitive industries like coffee and cocoa production, packaging automation can be the difference between profit and loss.

Key Features of an Automatic Powder Cocoa Coffee Food Packaging Machine

1. High Efficiency

Most machines can produce 30–60 packs per minute, with some industrial models reaching over 100 packs/min depending on the product and packaging size.

2. Intelligent Control Systems

Touchscreen PLC controls allow operators to adjust package size, weight, and sealing temperature easily.

3. Precision Filling Technology

The auger filler system guarantees accurate doses with minimal error margin (<1g in many cases).

4. Hygiene and Safety Standards

Food-grade stainless steel materials and easy-to-clean parts reduce contamination risks.

5. Flexible Packaging Options

Supports pillow bags, stick packs, stand-up pouches, zipper bags, and cans.

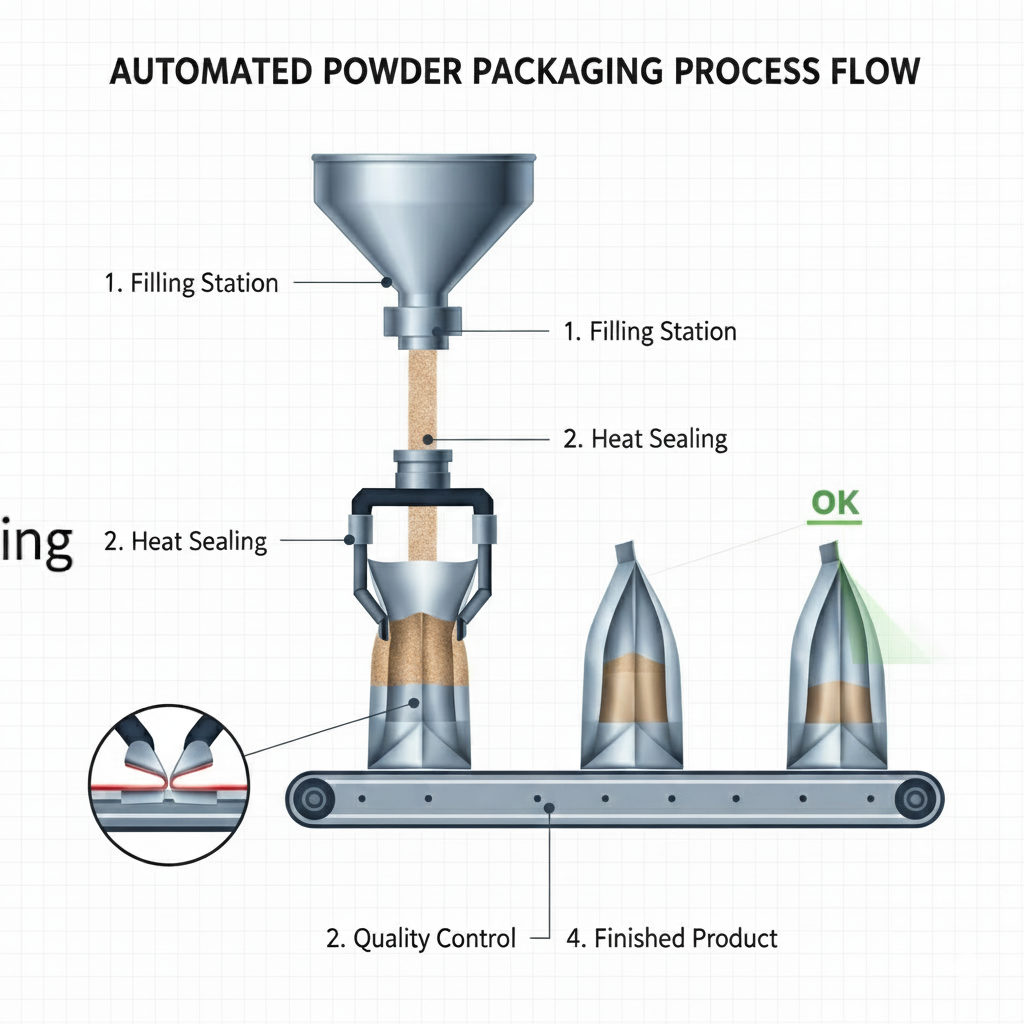

How the Machine Works – Step-by-Step Process

- Powder Loading

Powder is fed into the hopper manually or via conveyor from a storage silo. - Weighing & Dosing

A precisely controlled auger measures the correct weight according to pre-set parameters. - Filling

Powder is dispensed into the open packaging material. - Sealing

Heat sealing or ultrasonic sealing ensures the package is airtight. - Cutting & Discharge

Packages are cut from the film and discharged to the conveyor belt for collection.

Applications in Different Industries

- Coffee Industry – Instant coffee powder, ground coffee, espresso blends.

- Cocoa & Chocolate Industry – Pure cocoa powder, drinking chocolate mixes.

- Nutritional Products – Protein powder, whey powder, meal replacements.

- Baking & Cooking – Flour, sugar, yeast powder, baking soda.

- Spices & Seasonings – Pepper, curry powder, chili powder.

- Non-Food Powders – Detergent powder, chemical powders (non-toxic).

Technical Specifications (Example)

Buying Guide – How to Choose the Right Machine

When selecting an automatic powder coffee packaging machine, consider:

- Production Output Needs – Small shops vs. large factories.

- Powder Flow Characteristics – Some powders are free-flowing, others are sticky and need special handling.

- Packaging Material – Laminated film, kraft paper, aluminum foil, etc.

- Budget & ROI – Calculate your return on investment based on expected efficiency gains.

- After-Sales Support – Ensure the supplier offers training, spare parts, and maintenance.

Maintenance Tips for Longer Lifespan

- Regular Cleaning – Remove powder residues after each shift.

- Lubrication – Keep moving parts lubricated to reduce wear.

- Calibration – Periodically check weighing accuracy.

- Replace Worn Parts – Timely replacement prevents bigger breakdowns.

The Future of Powder Packaging Machines

Advances in automation will bring:

- AI integration for predictive maintenance.

- Energy-saving designs to reduce operational costs.

- More eco-friendly packaging materials.

- Faster speeds without compromising quality.

Conclusion

The Automatic Powder Cocoa Coffee Food Packaging Machine is a powerful investment for any business dealing with powdered products. It boosts production efficiency, guarantees consistent quality, and meets strict hygiene standards, making your product line more competitive in today’s market.

Whether you’re packaging coffee powder, cocoa powder, or nutritional supplements, automated packaging is the way forward for faster output, cost savings, and long-term growth.