Introduction

In modern pharmaceutical manufacturing, efficiency, accuracy, and compliance are non‑negotiable. The NJP‑800 capsule filling machine from HIJ Machinery is engineered to meet these standards, delivering consistent output for medium‑scale production facilities. This fully automatic machine streamlines the capsule‑filling process, saving labor, reducing waste, and ensuring every batch meets strict GMP requirements. It is ideal for pharmaceutical factory owners, production managers, and equipment procurement specialists seeking a reliable mid‑capacity solution.

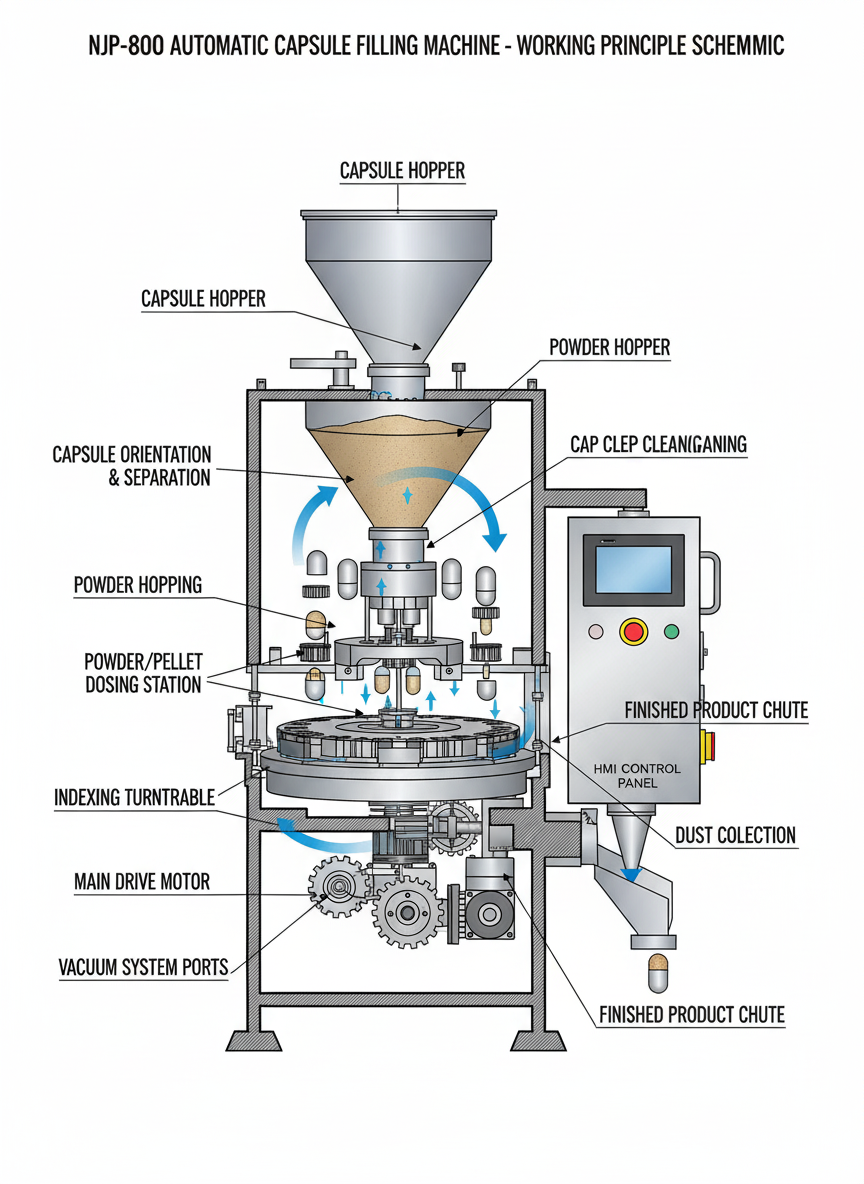

Working Principle of the NJP-800 Capsule Filling Machine

The NJP‑800 operates on a continuous rotary motion principle, enabling smooth, high‑speed capsule filling. The process involves:

- Capsule Feeding & Orientation

Empty capsules are loaded into the feed hopper, then automatically oriented and separated into caps and bodies using a vacuum separation system. - Dosing and Filling

The dosing system measures an exact quantity of powdered, granular, or pelletized material according to pre‑set parameters. Each capsule body is filled with the measured material. - Capsule Closing

Filled bodies are re‑joined with their caps, securely locked to prevent leakage or contamination. - Output and Quality Control

Completed capsules exit via an automatic chute. Optional rejection mechanisms remove defective capsules.

This automated sequence minimizes human handling, reducing the risk of contamination and ensuring production speed and accuracy.

Key Specifications

| Specification | NJP‑800 Details |

|---|---|

| Output Capacity | ~48,000 capsules per hour |

| Suitable Capsule Sizes | #00, #0, #1, #2, #3, #4 (adjustable) |

| Filling Materials | Powder, pellets, granules |

| Power Requirement | 3‑phase, 380V/50Hz (customizable) |

| Installed Power | Approx. 4 kW |

| Dimensions (L × W × H) | 980 × 980 × 1,980 mm |

| Net Weight | ~900 kg |

| Noise Level | ≤ 75 dB |

| Compliance | GMP standards, stainless steel contact parts |

These technical parameters make the NJP‑800 a versatile capsule filling machine capable of meeting mid‑range production targets while maintaining strict quality control.

Main Features and Advantages

1. Precision Dosing

Advanced metering systems ensure each capsule contains an accurate amount of product, reducing weight variation and minimizing wastage.

2. Robust Construction

Manufactured with high‑grade stainless steel, the NJP‑800 offers durability, easy cleaning, and full compliance with GMP requirements.

3. Stable Continuous Operation

Its rotary design supports uninterrupted production, resulting in consistent throughput across long runs.

4. User‑Friendly Interface

Touch‑screen controls and digital displays simplify parameter setting, real‑time monitoring, and troubleshooting.

5. Adaptable Capsule Size Changeover

Quick‑change tooling makes switching between different capsule sizes fast and efficient, limiting downtime.

6. Cost‑Effective Performance

As a mid‑range model, the NJP‑800 provides excellent output without the higher operating costs of large‑capacity machines.

Applications and Suitability

The NJP‑800 capsule filling machine is ideal for:

- Pharmaceutical companies producing medium volumes of prescription medications or nutraceuticals.

- Nutritional supplement producers requiring precise filling of herbal powders, vitamins, or plant extracts.

- Contract manufacturing organizations (CMOs) offering capsule packaging services.

- Facilities with frequent product changeovers yet requiring stable output.

It supports a wide range of capsule types and formulations, making it a versatile addition to any GMP‑compliant manufacturing line.

Maintenance and Operation Tips

To ensure maximum performance and equipment longevity:

- Regular Cleaning

Clean all contact parts after each production run to prevent material build‑up and cross‑contamination. - Scheduled Lubrication

Follow the manufacturer’s recommended lubrication schedule for moving parts to avoid wear and tear. - Operator Training

Train staff on machine settings, troubleshooting, and safety procedures to prevent mishandling. - Material Preparation

Ensure powders and granules meet flowability and moisture specifications for accurate dosing. - Preventive Maintenance

Conduct periodic inspections, replace worn parts promptly, and update calibrations as needed.

Adhering to these practices ensures the NJP‑800’s stability, accuracy, and production efficiency over the long term.

Conclusion – Why Choose HIJ Machinery’s NJP-800 Capsule Filling Machine

The NJP‑800 capsule filling machine from HIJ Machinery strikes the perfect balance between output, precision, and cost efficiency. With its automatic operation, GMP‑compliant design, and adaptability for various capsule sizes, it is an excellent choice for medium‑scale pharmaceutical and nutraceutical production.

Whether you’re expanding capacity, upgrading from semi‑automatic equipment, or starting a new production line, the NJP‑800 provides a proven, reliable solution.

Call to Action:

Contact HIJ Machinery today to discuss your production needs and request a detailed quotation. Our technical team is ready to assist with machine selection, installation, and operator training.