Description:

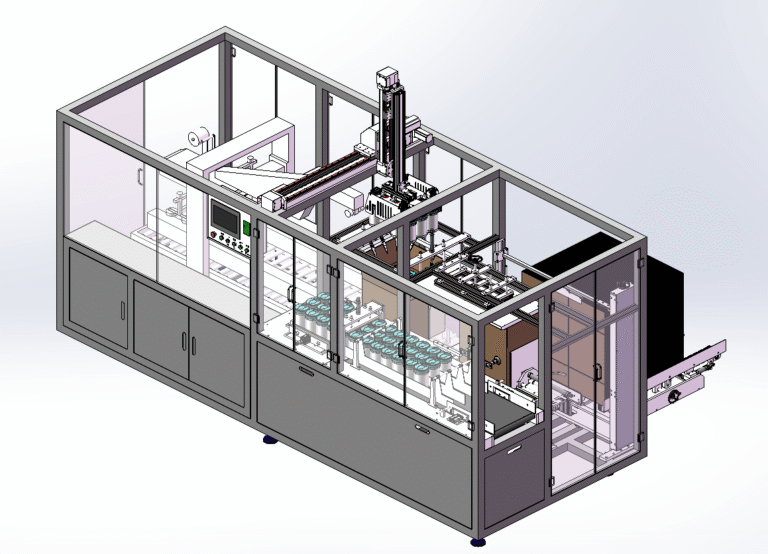

This case packing line performs case erector, case packer, and case sealer, making it suitable for large-scale production of pharmaceutical and daily chemical products. The equipment boasts a stable production efficiency of 1-5 cartons per minute. Each station features features such as missing carton detection, incoming product detection, overload protection, and carton position detection, enabling fully automated, unmanned packaging operations.

Features:

1. This complete machine integrates automatic unpacking, packing, and sealing functions in a compact size and boasts a high degree of automation.

2. The machine’s alloy frame with a plexiglass cover and balcony-style design allow for open access and easy cleaning, creating an elegant and aesthetically pleasing experience, fully complying with GMP requirements.

3. A high-end French Schneider PLC control system with three servo motors.

4. Dual servo manipulators with imported slide rails.

5. Each workstation is precisely positioned, equipped with photoelectric detection, fault alarms, and material protection.

6. Material position, placement, and tape inspection ensure finished product quality.

7. Adjustment of workstations using self-locking wrenches, rocker levers, and handwheels allows for rapid interchangeability, ensuring high versatility.

8. An automatic backing plate placement mechanism (optional).

-1-1-768x768.jpg)