Introdução

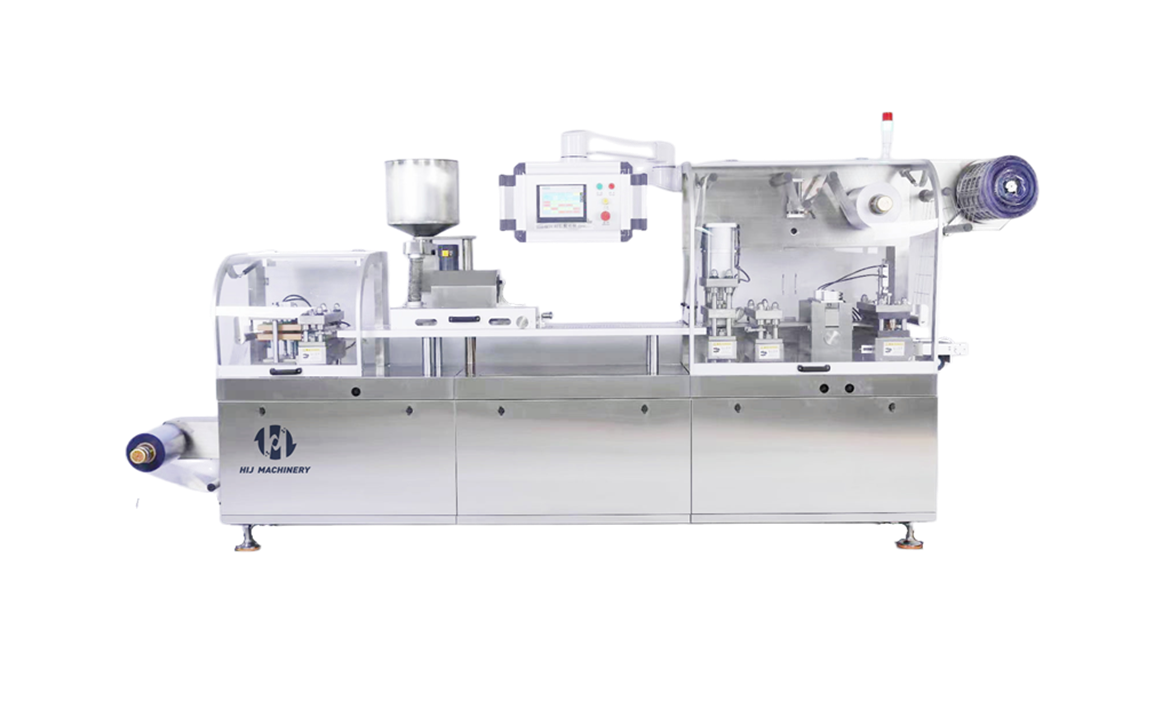

In the competitive pharmaceutical and nutraceutical industries, efficient and reliable packaging is essential to maintain product integrity, enhance shelf appeal, and ensure compliance with international quality standards. The DPP‑260 capsule blister packaging machine de HIJ Machinery Co., Ltd. is engineered to meet these demanding requirements.

Designed for medium‑ to large‑scale production, the DPP‑260 integrates precision forming, sealing, and cutting processes into one streamlined operation. Whether you manufacture hard gelatin capsules, tablets, or soft gels, this advanced blister packaging machine delivers consistent performance, minimal waste, and high output—all in a compact footprint that complies with GMP standards.

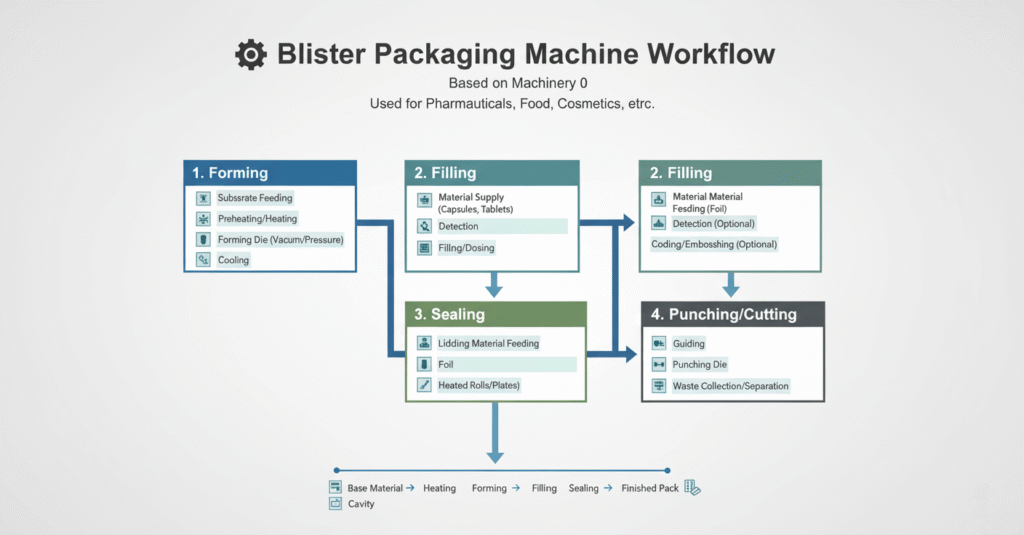

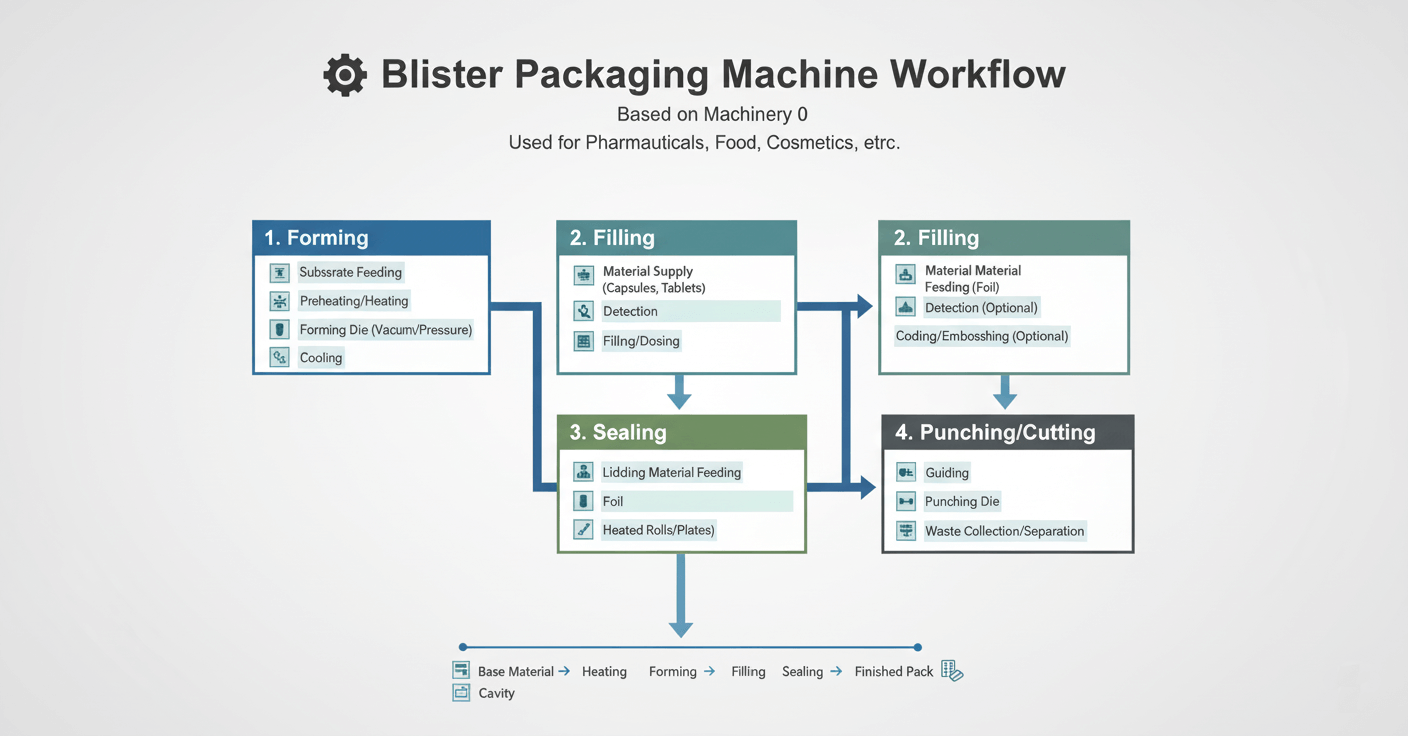

Working Principle

O capsule blister packaging machine operates through a continuous, fully automated workflow that includes plastic film forming, product feeding, heat sealing, batch coding, and punching.

- Forming: PVC or PVDC film is heated and shaped into blisters by a forming mold.

- Filling: The machine automatically counts and places capsules or tablets into each formed cavity using a precision feeder.

- Sealing: Aluminum foil (PP/Alu or Alu/Alu) is heat‑sealed over the filled blisters, ensuring airtight protection against moisture, light, and contamination.

- Batch Coding: Date and batch number are embossed or printed during the sealing process.

- Cutting: The finished blister sheets are accurately cut according to set parameters, ensuring uniform and clean edges.

This seamless process guarantees product quality and safety while reducing human error and downtime.

Especificações técnicas

| Artigo | Especificação |

|---|---|

| Modelo | DPP‑260 |

| Max Forming Area | 250 × 120 mm |

| Max Forming Depth | 12 mm (customizable) |

| Punching Frequency | 20–45 times/min |

| Saída | Up to 9,000 blisters/hour (depending on product size) |

| Fonte de alimentação | 380 V / 50 Hz / 6.5 kW |

| Air Pressure | 0.5–0.7 MPa |

| Air Consumption | ≥ 0.2 m³/min |

| Cooling Water | 60 L/h (circulating) |

| Machine Dimensions | 3600 × 700 × 1600 mm |

| Peso | Approx. 1200 kg |

| Materiais | Main contact parts in SUS304 stainless steel |

| Conformidade | cGMP, CE |

(Technical data may vary depending on blister size and configuration.)

Key Features

High Precision Forming and Sealing

The DPP‑260 capsule blister packaging machine uses advanced forming molds and temperature‑controlled heating plates to ensure precise PVC and aluminum film shaping. The sealing station applies uniform pressure and heat, achieving strong, leak‑proof seals that preserve product stability.

PLC Control and Touch‑Screen Interface

Equipped with Siemens PLC and an intuitive HMI, the machine enables easy parameter setting, fault diagnostics, and automatic monitoring of production status. Operators can quickly adjust speed, temperature, and cutting length for different product batches.

Compact and Hygienic Stainless Steel Design

All product‑contact parts are made of Aço inoxidável SUS304 and medical‑grade materials, offering corrosion resistance and easy cleaning. The ergonomic layout minimizes footprint while facilitating maintenance access.

Automatic Feeding System

Multiple feeding options—vibration feeder, brush feeder, or track feeder—accommodate capsules, tablets, and irregular shapes. The system ensures accurate filling without product mix‑up or breakage.

Advanced Cutting System

Servo‑controlled punching ensures precise cutting alignment between cavity and printed pattern, ideal for high‑end pharmaceutical packaging presentation.

Optional Add‑Ons

- Alu/Alu packaging configuration

- Vision inspection system

- Automatic rejection of defective blisters

- Inkjet or emboss batch coding system

Applications

O DPP‑260 capsule blister packaging machine is widely applicable in:

- Pharmaceutical capsule and tablet packaging

- Nutraceutical and dietary supplement production

- Healthcare and veterinary product packaging

- Ampoules or small medical device blistering

- Research and development laboratories

Its versatility makes it a cost‑effective choice for both high‑volume pharmaceutical factories and contract manufacturing facilities seeking flexible blister packaging solutions.

Advantages of the DPP‑260 Capsule Blister Packaging Machine

- High Production Efficiency – With a punching frequency of up to 45 cycles per minute, the DPP‑260 increases throughput and reduces unit cost.

- Excellent Sealing Quality – Uniform heat distribution guarantees airtight, tamper‑evident packaging.

- User‑Friendly Operation – The touch‑screen interface simplifies setup and reduces operator training time.

- Low Maintenance – Durable components and modular design minimize downtime and spare‑part replacement frequency.

- Energy Saving – Optimized heating zones and precision temperature control lower power consumption.

- cGMP‑Compliant Design – Smooth, contamination‑free surfaces meet international pharmaceutical standards.

- Flexible Mold Changeover – Quick mold replacement enables rapid product switchover without complex adjustments.

Why Choose HIJ Machinery Co., Ltd.

HIJ Machinery Co., Ltd. is a leading manufacturer of capsule filling machines, blister packaging machines, e cartoning machines. With years of engineering experience, we serve pharmaceutical, healthcare, and nutraceutical customers worldwide.

Our factory integrates R&D, design, manufacturing, and after‑sales support, ensuring every piece of equipment delivers stable performance, excellent accuracy, and long service life. We also provide OEM/ODM services, customized solutions, and on‑site technical training.

By partnering with HIJ Machinery, you gain:

- Proven reliability backed by international clients

- Comprehensive validation documentation support

- Competitive pricing and responsive technical assistance

- Fast global shipping and spare‑parts availability

Conclusion and Call to Action

O DPP‑260 capsule blister packaging machine represents the ideal balance of performance, reliability, and GMP‑compliant design for modern pharmaceutical and nutraceutical production lines. With its precision control system, durable stainless‑steel structure, and flexible configuration options, it is an excellent investment for companies seeking higher productivity and consistent packaging quality.

Contacte a HIJ Machinery Co., Ltd. hoje mesmo to discuss your blister packaging requirements or request a customized quotation. Our engineering team is ready to support your project from concept to production.