What is a Prefilled Syringe?

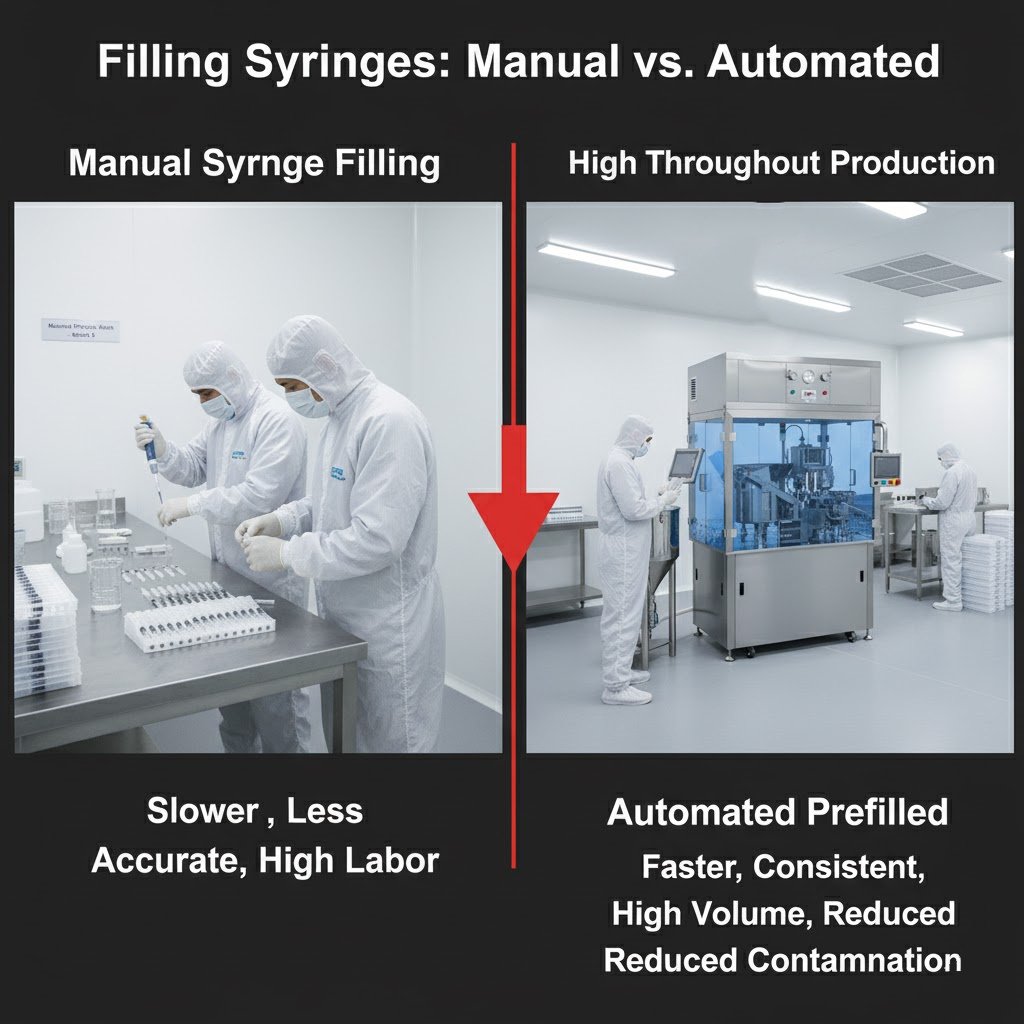

A prefilled syringe refers to a single-use, disposable syringe that is already filled with a measured dose of medication prior to use. These syringes are widely used in the pharmaceutical industry due to their convenience, safety, and dosage accuracy. Prefilled syringes help reduce contamination, improve patient compliance, and save time during medical procedures.

What is a PFS Filling Machine?

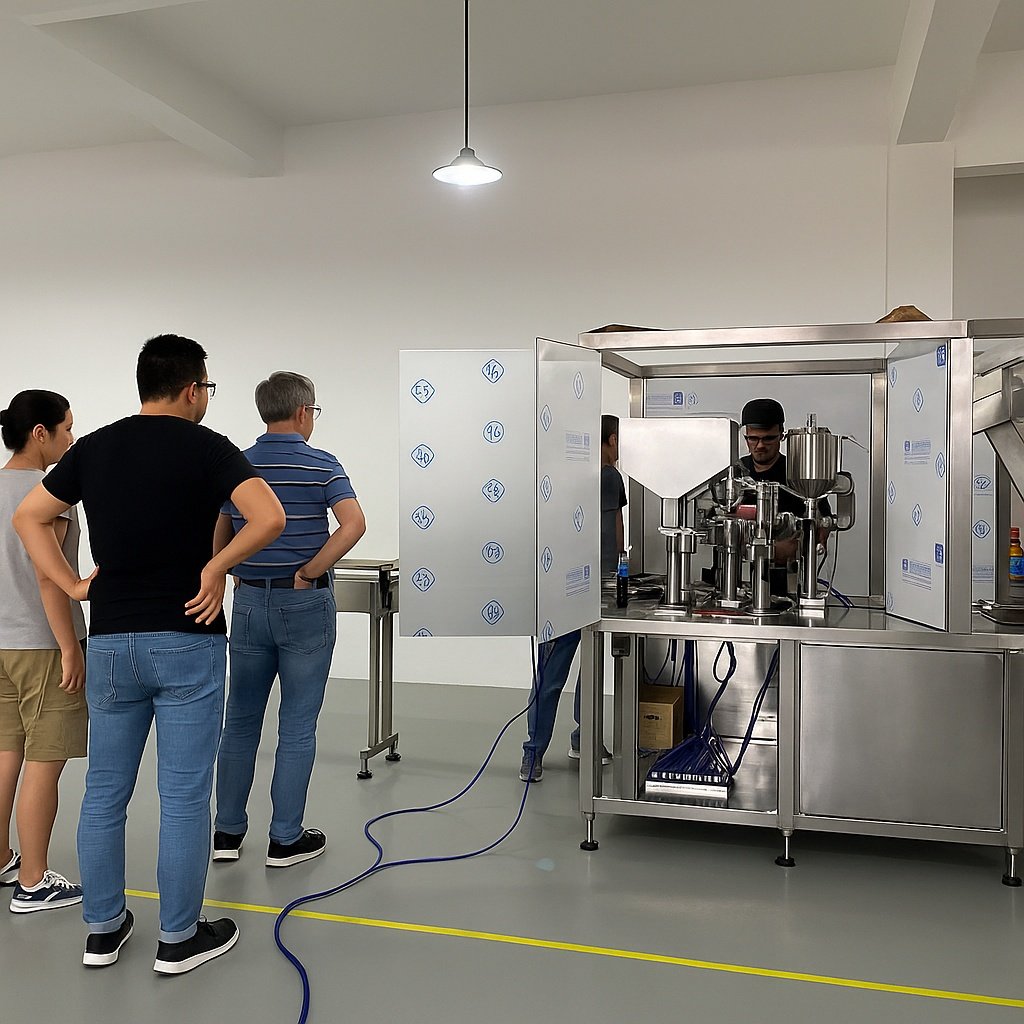

A PFS filling machine (Prefilled Syringe Filling Machine) is a highly automated piece of equipment used to fill and seal prefilled syringes with precise volumes of pharmaceutical liquids. It ensures consistency, sterility, and accuracy throughout the filling process. These machines can handle various syringe sizes and are equipped with advanced technologies such as robotic handling, laminar airflow systems, and real-time monitoring sensors.

The machine plays a significant role in modern pharmaceutical production, helping manufacturers reduce manual errors and improve overall efficiency.

The Cost of a Disposable Syringe Machine

O cost of a disposable syringe machine varies depending on functionality, level of automation, production capacity, and compliance requirements. Small-scale filling units may start from tens of thousands of dollars, while fully automated prefilled syringe filling and capping machines for large production lines can range from $100,000 to several hundred thousand dollars. Price fluctuation is also influenced by customization needs and quality certification standards such as GMP and CE compliance.

Investing in a high-quality syringe filling machine ensures long-term savings through reduced wastage, higher throughput, and consistent product quality.

Advantages and Disadvantages of Prefilled Syringes

Vantagens:

- Sterility and Safety:Prefilled syringes minimize contamination risk by eliminating the need for manual drug preparation.

- Efficiency:They reduce preparation time for medical professionals.

- Accuracy:Each syringe contains a precise dosage, avoiding medication errors.

- Patient Convenience:Easier self-administration of medicine.

Disadvantages:

- Higher Manufacturing Cost:The precision and sterility requirements increase production expenses.

- Storage Limitations:Prefilled syringes can be sensitive to temperature and require controlled environments.

- Material Compatibility:Some drugs may interact with syringe materials over time.

How Syringe Filling Machines Improve the Pharmaceutical Process

Moderno automatic syringe filling machines integrate advanced servo systems and PLC control to achieve efficient and precise liquid handling. They operate in sterile conditions, ensuring pharmaceutical-grade cleanliness. By combining filling and capping automation, manufacturers achieve consistent sealing integrity and avoid contamination risks.

These machines are compatible with a wide range of injectable products, including vaccines, insulin, and biotech formulations, making them essential for global pharmaceutical production.

Conclusion: The Future of Prefilled Syringe Filling Technology

The demand for prefilled syringe filling machines continues to grow worldwide, driven by advancements in injectable drug formulations and stringent regulatory standards. As pharmaceutical companies pursue automation and precision, PFS filling machines are becoming indispensable in ensuring product safety, sterility, and cost efficiency.

Investing in cutting-edge syringe filling technology helps manufacturers stay ahead in the competitive global healthcare market.