Введение

Your solution is an automatic form-fill-seal (FFS) blister system that thermoforms two plastic film rolls into clear, unit-dose bottles, then fills, heat-seals the upper and lower films, and die-cuts—all on one compact line. Ideal for cosmetics serums, pharma unit-dose liquids, and personal care products requiring hygienic, tamper-evident, mono-material packaging with strong shelf appeal.

What Is Blister Packaging?

Blister packaging uses a thermoformed cavity and a mating film to enclose and protect contents from moisture, oxygen, and contamination. In an FFS twin-film bottle line, both the cavity and the closure are plastic films: the cavity is shaped like a mini bottle, filled, and then heat-sealed to a top film—combining clarity, barrier performance, and unit-dose convenience without aluminum lidding.

Blister Packaging in Pharmacy

In pharmacy, blister formats cover tablets, capsules, and increasingly, single-dose liquids. Benefits include adherence support, accurate dosing, tamper-evident options, and minimized contamination. FFS twin-film blister bottles extend these benefits to eye/ear drops, serums, and topical solutions while supporting mono-material sustainability and easier recycling.

Why Some Pharmacies Reduce Blister Packs

- Labor and cost pressures in manual pharmacy blistering

- Recycling challenges of mixed-material blisters; shift to mono-material plastics

- Better traceability and GMP compliance via manufacturer-level automation These trends drive demand for automatic FFS blister machines that deliver consistent quality and tamper-evident, mono-material unit-dose packs.

FFS Process for Single-Dose Bottles

- Dual plastic film unwinding and preheating (e.g., PET/PE, PP, PVC/PVDC)

- Thermoforming tooling creates precise bottle-shaped cavities and necks

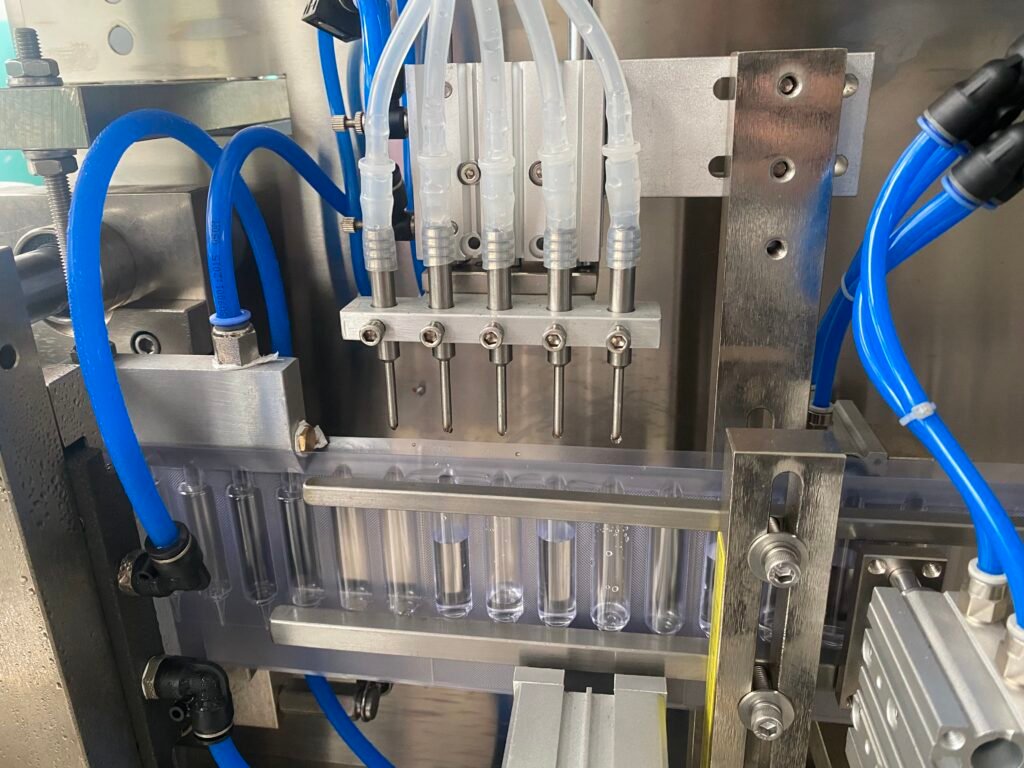

- Servo dosing fills 0.5–10 mL accurately with hygienic circuits (CIP/SIP)

- Heat-pressure sealing bonds upper and lower films for barrier integrity and tamper evidence

- Die-cutting and punching yield clean edges and easy tear/snap features

Types of Blister Packing Machines

- Automatic blister packaging machine (FFS twin-film bottle): integrated forming, filling, heat-sealing, cutting

- Small blister packaging machine: compact footprint for pilots, small batches, fast changeovers

- Semi-automatic variants: operator-assisted steps for specialty liquids

- Specialty modules: cap packaging blister and empty bottle packing for kit assembly

Costs and Budgeting

- Small FFS blister machine for single-dose plastic bottles: USD 12,000–35,000

- Fully automatic lines with vision/serialization: USD 40,000–150,000+

- Tooling/format sets: USD 1,500–8,000 per SKU

- Validation, installation, spares: add 10–20% Note: Prices vary by twin-film structures (PVC/PVDC, PET/PE, PP), cleanroom compatibility, and add-ons like inline film printing, code readers, and reject systems.

Key Features to Evaluate

- Accurate bottle cavity forming for retention and leak prevention

- Hygienic liquid circuits with precise servo filling and anti-drip nozzles

- Uniform twin-film heat-sealing (temperature, pressure, dwell) for high barrier performance

- Film-to-film compatibility and seal layer selection for liquid blister packaging

- Vision inspection for presence, fill level, seal integrity, date/lot

- Quick changeover tooling for multiple sizes and materials

- Compact design suitable for limited floor space

Приложения

- Cosmetics/skincare serums (ampoule-like blister bottle)

- Pharma and hospital unit-dose liquids, topical solutions

- Travel/sample packs and clinical trial kits

- Accessory bundling via cap packaging blister

- Kit assembly with empty bottle packing modules

Configuration Guidance

- Define product: cavity size, neck design, fill volume, viscosity, opening method

- Choose forming and barrier films by OTR/WVTR targets (e.g., PET/PE, PP, PVC/PVDC)

- Engineer filling: peristaltic, piston, or gear pumps; CIP/SIP; dosing validation

- Select twin-film seal layers: match peel strength, tamper evidence, and process window

- Controls: PLC + HMI, recipes, web alignment and jam sensors

- Quality: inline vision, leak testing, printing (TTO/CIJ/thermal inkjet), serialization

- GMP validation: IQ/OQ/PQ and documented parameters

Suppliers and Sourcing Tips

- Compare tooling lead times, after-sales service, spare parts

- Request sample trials with your liquid for forming, fill accuracy, and seal strength

- Evaluate CE/FDA GMP readiness and documentation, especially when sourcing from blister machine China manufacturers

- Confirm materials supply and sustainability options (mono-material twin films, recyclable structures)

FAQs

Q1: Why are pharmacies stopping blister packs?

A: Many reduce in-house blistering due to labor, sustainability, and compliance burdens, favoring manufacturer-sealed unit-dose packs from automatic FFS lines.

Q2: How much does a packsize or small blister machine cost?

A: Small FFS machines typically USD 12,000–35,000; fully automatic systems USD 40,000–150,000+, plus tooling and validation.

Q3: What types of blister packing machines are available?

A: Automatic FFS, small compact, semi-automatic, and specialty modules for caps and empty bottle packing.

Q4: What is blister packaging and how does it apply to liquids?

A: A thermoformed cavity closed by a second plastic film; for liquids, choose appropriate barrier films, controlled twin-film sealing, and hygienic filling for unit-dose plastic bottles.