Введение

In my 20 years as a packaging machinery engineer, I’ve seen the pouch market evolve from a niche option to a global standard. From coffee beans and protein powder to sauces and pharmaceuticals, flexible pouches offer convenience, excellent branding real estate, and reduced shipping costs. But this boom has a downside: a flooded market of machines that look similar on paper but perform drastically differently in the real world. This guide is written from an engineer’s perspective to help you look “under the hood,” avoid common pitfalls, and invest in a machine that becomes a production asset, not a constant headache.

The Reality of Modern Packaging Operations

Market Trends: The Pressure is On

The demand for pouched products is surging, but so are the challenges. Labor costs are rising globally, forcing factories to seek higher levels of automation. Consumers expect perfect, consistently filled packages every time. And for international businesses, the emphasis has shifted from simply buying the cheapest machine to investing in long-term stability and reliable after-sales support. The pressure to produce more, faster, and with fewer errors has never been greater.

Common Pain Points I See Daily

When I visit factories, I hear the same frustrations over and over. These aren’t just minor inconveniences; they are issues that directly impact profitability.

- “The speed never matches the brochure”: A machine rated for 60 bags per minute (BPM) struggles to consistently run at 40 without jamming or creating bad seals.

- “Our sealing is a nightmare”: Inconsistent heat or pressure leads to weak seals that leak during shipping, resulting in customer complaints and returned products.

- “Film changeovers take forever”: A simple roll change turns into a 30-minute ordeal of re-threading and re-aligning, killing your Overall Equipment Effectiveness (OEE).

- “Cleaning is so difficult”: Poorly designed machines have hard-to-reach areas where product builds up, creating hygiene risks (critical in food/pharma) and causing cross-contamination.

- “The pneumatics are unreliable”: Air pressure fluctuations cause inconsistent cylinder movements, leading to variations in sealing pressure and cutting accuracy.

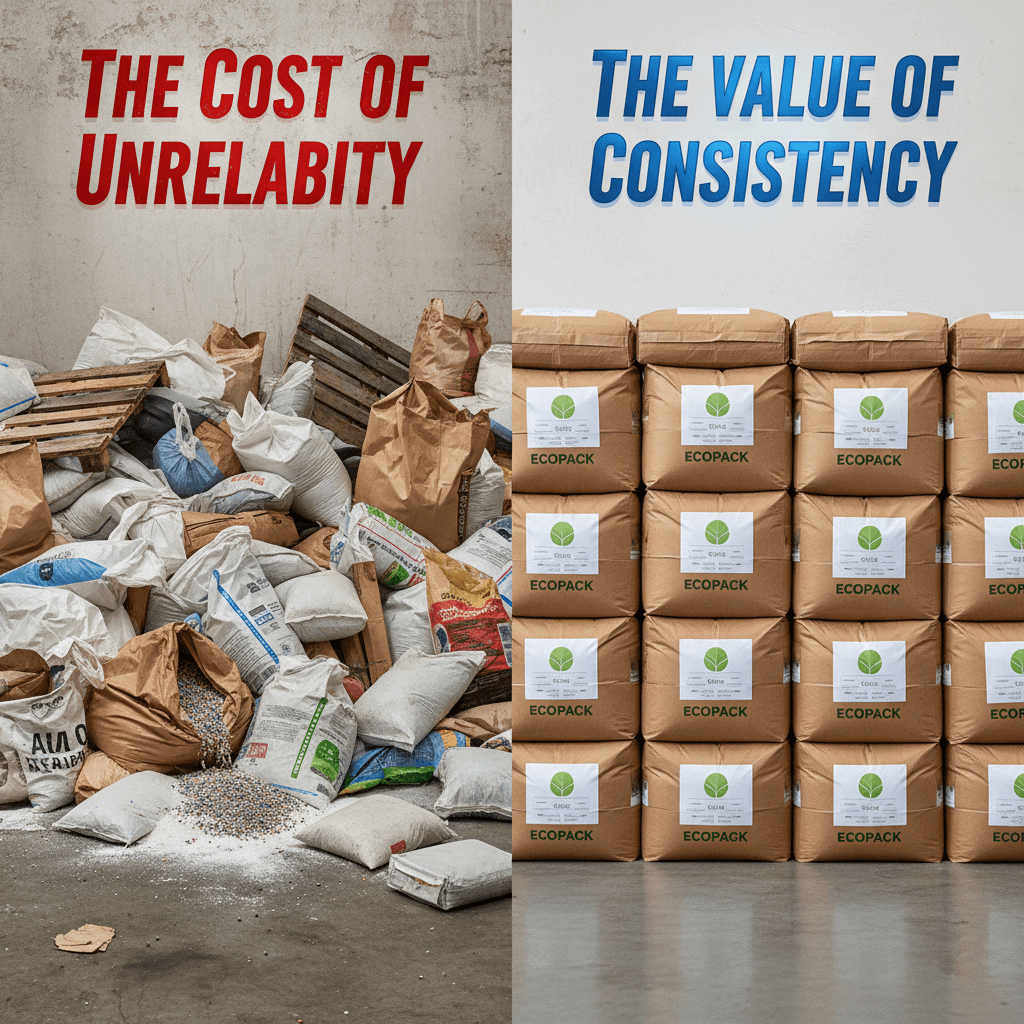

The Most Common (and Costly) Mistake

The single biggest mistake I see is purchasing based on price and a feature checklist alone. A buyer sees two machines with the same “claimed” speed and bag size range, and chooses the one that’s 20% cheaper. Six months later, the hidden costs appear: excessive film waste, constant downtime for adjustments, and the need for a dedicated operator to babysit the machine. The “cheaper” machine ends up costing far more in the long run.

Why You Must Solve These Problems

Unreliable packaging is a bottleneck that chokes your entire production line. It limits your growth, damages your brand’s reputation, and leads to staff frustration. A reliable packaging machine isn’t a cost center; it’s a revenue enabler.

An Engineer’s Technical Breakdown

Common Technologies: Pneumatic vs. Servo

At the heart of most Vertical-Form-Fill-Seal (VFFS) machines are two core motion control philosophies:

- Full Pneumatic: The traditional approach. Simple, cheap, and easy to understand. Cylinders driven by compressed air perform actions like sealing and cutting. However, they are susceptible to air pressure variations, are generally slower, and offer less precision.

- Servo-Driven: A modern, high-performance approach. Electric servo motors control key movements like film pulling and jaw sealing. They are incredibly precise, repeatable, and fast. A servo-driven film pull ensures every bag is the exact same length, every time. A servo-driven sealing jaw provides precise, consistent pressure, independent of air supply fluctuations.

How Technical Specs Really Impact Production

Don’t just read the numbers; understand what they mean.

- Speed (BPM): This is always a range. It’s heavily dependent on your product (powders are dusty, liquids can splash), bag length, and film material. A machine with servo-driven film pulling will achieve its top-end speed more consistently and reliably than a mechanical or pneumatic equivalent.

- Filling System: The “filler” (e.g., auger for powders, pump for liquids) is just as important as the bagger. An anti-drip nozzle isn’t a luxury for liquids and pastes; it’s a necessity to prevent product from contaminating the seal area, which is a primary cause of leaky pouches.

- Frame & Materials: Look for a heavy, robust frame (it reduces vibration at high speeds) and high-quality stainless steel (SUS304 for most foods, SUS316 for corrosive products or pharmaceuticals).

How to Judge a Professional-Grade Machine

When I inspect a machine, I ignore the marketing and look for these signs of quality engineering:

- Component Brands: Check the brands of the PLC, touch screen, and servo motors. Using globally recognized brands like Siemens, Schneider, or Panasonic means reliability and easier access to replacements.

- Wiring and Pneumatic Routing: Open the control cabinet. Are the wires neatly organized in ducts with clear labels? Or is it a “rat’s nest”? Clean wiring is a sign of a disciplined engineering team and makes troubleshooting dramatically easier.

- Weld Quality and Finish: Look at the welds on the frame. Are they smooth, continuous, and polished? Or are they rough and unfinished? A high-quality finish isn’t just for looks; it eliminates crevices where bacteria can grow.

Application and Limitations

These machines are workhorses for food, pharmaceutical, chemical, and supplement industries. They excel at creating standard pillow pouches or gusseted bags from a roll of film. However, they are not the solution for everything. If you need pre-made pouches (like stand-up pouches with zippers), you need a different machine type (a rotary premade pouch machine).

Real-World Applications & Success Stories

Case Study: The Coffee Roaster’s Bottleneck

A client in the specialty coffee market was using an older, mechanically-driven machine. They struggled with inconsistent fill weights and their film would often jam, forcing a line stop. After upgrading to a machine with a servo auger filler and servo-driven film transport, they saw:

- Actual Output Increase: From an average of 25 BPM to a stable 55 BPM.

- Product Giveaway Reduction: Fill accuracy improved from ±3g to ±0.5g, saving them thousands of dollars in overweight bags per month.

- Downtime Slashed: Automatic film alignment and a more forgiving film path reduced changeover and jam-clearing time by 75%.

Industry-Specific Demands

- Фармацевтические препараты: Require GMP-compliant design, SUS316 contact parts, and tool-less disassembly for easy, verifiable cleaning.

- Food (e.g., Sauces, Powders): Demand reliable anti-drip filling, dust-extraction ports for powders, and strong, airtight seals for freshness.

- Health Supplements: Precision dosing is paramount. A servo-auger filler is non-negotiable for ensuring every pouch has the correct amount of active ingredient.

The HMK Series Advantage: Engineered for Reality

Our design philosophy is based on solving the real-world problems I’ve outlined. We build machines for continuous, stable production, not just to win on a spec sheet.

Introducing the HMK-1600, HMK-2000, and HMK-2600

These models represent a scalable solution for VFFS packaging, built on a foundation of engineering excellence.

Core Features That Address Your Pain Points

- Stability and Speed (The “No Surprises” Promise): Our HMK series utilizes full servo-driven systems for film pulling and horizontal sealing. This is why we can confidently promise stable high-speed operation. The motion is controlled by a precise electronic signal, not fluctuating air pressure. This directly solves the “speed doesn’t match the brochure” problem.

- Film Versatility (Not “Picky” with Film): We’ve engineered the film transport path and integrated high-quality PID temperature controllers. This combination allows our machines to handle a wider tolerance of film materials and thicknesses, reducing the frustrating jams common on less-advanced machines.

- Upgraded Anti-Drip Nozzles: For liquid and paste clients, our custom-designed shut-off nozzles feature a “suck back” function that cleanly cuts the product stream, ensuring a clean seal area and eliminating product waste.

- Operator Safety and Efficiency: All our machines come standard with fully interlocked safety doors. If a door is opened, the machine stops, protecting your team. Furthermore, features like tool-less former changes and automatic film tracking are designed to reduce reliance on highly-skilled operators and save valuable labor time.

Our Edge Over the Competition

Many competitors in our price range use servo motors for film pulling but cut costs by using a pneumatic cylinder for the critical horizontal sealing function. This creates a performance bottleneck. The HMK series’ use of servo-driven sealing jaws provides superior control over pressure and timing, resulting in more consistent, higher-quality seals at greater speeds—a tangible difference you will see in your finished product.

OEM/ODM Services: Your Engineering Partner

We are not just a manufacturer; we are an engineering company. We offer full OEM/ODM services to integrate our machines into your unique production line or develop custom solutions for challenging products.

Frequently Asked Questions (FAQ)

Q1: Your machine is rated at 80 BPM. Can I really run it at that speed? A: Yes, under the right conditions. 80 BPM is achievable with a short bag length, free-flowing product, and quality film. When you contact us, we will give you a realistic speed estimate based on your specific product and bag size, not a generic maximum.

Q2: Will your machine work with my current bags and film? A: Very likely, yes. The “former” on the machine is what shapes the bag, and we custom-make this part to your exact bag dimensions. We recommend sending us a roll of your film for testing to guarantee perfect compatibility.

Q3: The price difference between your servo model and a competitor’s pneumatic model is significant. Is it worth it? A: This is a question of ROI. A servo machine might cost more upfront, but it delivers higher stable speeds, less product/film waste, and requires less operator intervention. We can help you calculate the payback period. For many clients, the increased output and reduced waste means the machine pays for the price difference in under 12 months.

Q4: How do I know the machine is durable? A: It comes down to three things: a heavy-duty frame to minimize vibration, the use of high-quality stainless steel (SUS304/316), and sourcing critical electronics and pneumatics from globally-respected brands. We encourage you to compare the build quality side-by-side.

Conclusion and Recommendations

When Should You Invest in a Machine Like the HMK Series?

- Your current packaging line is the bottleneck preventing you from meeting sales demand.

- You are experiencing unacceptable levels of product returns due to poor seal quality.

- Rising labor costs or operator shortages are impacting your production.

- You are launching a new product and want to ensure a professional, reliable packaging process from day one.

Choosing the Right Model

- For Start-ups & Lower Volume (up to 40-50 BPM): Сайт HMK-1600 offers a professional-grade entry point with key reliability features.

- For Established Production (up to 60-70 BPM): Сайт HMK-2000 is our most popular model, offering an ideal balance of high speed, versatility, and value.

- For Large-Scale, High-Speed Lines (70+ BPM): Сайт HMK-2600 is our high-performance flagship, engineered for maximum throughput and automation.

Let Us Help You Choose: The Data We Need

Making the right choice can be complex, but we can provide a precise, data-driven recommendation. Before you contact us, please try to prepare the following information. This will allow our engineers to give you the most accurate and helpful advice.

- Your Product: Is it a powder, granule, liquid, or paste? What is its density or viscosity?

- Your Bag: Bag type (pillow, gusset), dimensions (width and length). A photo or sample is perfect.

- Your Film: Material type (e.g., PET/PE, OPP/CPP), and thickness (in microns).

- Target Speed: How many bags per minute do you need to produce?

- Fill Weight/Volume: How much product goes into each bag, and what is the required accuracy (e.g., ±1g)?

- Factory Utilities: What is your factory’s power supply (Voltage/Phase/Hz) and do you have a stable compressed air supply?