Introduction: The Backbone of Modern Pharmaceutical Tablet Production

In today’s growing pharmaceutical and nutraceutical industries, efficiency and precision are critical in every stage of tablet manufacturing. A rotary tablet press machine is the heart of any tablet production line—transforming powder or granulated materials into uniform tablets with consistent weight, hardness, and shape.

As global manufacturers strive to improve productivity and maintain the highest quality standards, choosing the right high-speed tablet press becomes essential. HIJ Machinery Co., Ltd. meets these industrial needs with its advanced GZPK Series High-Speed Rotary Tablet Press Machines, designed for continuous, automated tablet production under GMP-compliant standards.

About the GZPK Series Rotary Tablet Press Machines

Сайт GZPK Series—comprising the GZPK-51, GZPK-65, и GZPK-83—represents HIJ Machinery’s latest generation of high-speed rotary tablet press machines. Each model is engineered with advanced mechanical design, robust performance, and intelligent control systems to ensure reliability, efficiency, and precision in pharmaceutical tablet production.

These machines are ideal for:

- Pharmaceutical manufacturers producing prescription or OTC tablets

- Nutraceutical companies producing vitamins and dietary supplements

- Food and chemical industries requiring compressed tablets or pellets

Whether producing small batches of specialized tablets or mass production of generic formulations, the GZPK Series provides scalability, accuracy, and durability for all industrial-grade tablet pressing requirements.

Технические характеристики

Below are the key specifications for each model in the GZPK Series:

| Модель | Количество станций | Max Output (tablets/hour) | Max Pressure (kN) | Максимальный диаметр планшета | Max Filling Depth (mm) | Turret Speed (rpm) |

|---|---|---|---|---|---|---|

| GZPK-51 | 51 | up to 370,000 | 100 | 25 | 20 | 65 |

| GZPK-65 | 65 | up to 470,000 | 100 | 25 | 20 | 65 |

| GZPK-83 | 83 | up to 600,000 | 100 | 25 | 20 | 65 |

- Weight and Dimensions: Compact design with stainless steel enclosure; easy integration into existing tablet production lines.

- Power Supply: Standard 380V / 50Hz (customizable for global markets).

- Control System: PLC-based operation with touchscreen interface for precise parameter adjustments.

Key Features and Advantages

1. High-Speed and High-Precision Tablet Production

The GZPK Series is designed for high throughput without compromising quality. Each rotary tablet press machine uses multi-station compression to produce thousands of tablets per minute, ensuring uniform weight and density throughout production batches.

2. Robust Compression and Consistency

With a maximum pressure of 100 kN, the GZPK-51/65/83 ensures precise formation of tablets with various hardness requirements—ideal for both pharmaceutical and nutraceutical formulations.

3. Stainless Steel Structure and GMP Compliance

All contact parts are made of high-grade stainless steel, offering excellent corrosion resistance and easy cleaning. The enclosed design prevents cross-contamination and fully complies with GMP and FDA standards, ensuring hygienic and safe pharmaceutical tablet production.

4. User-Friendly Automation System

Each model features an intuitive PLC control system with touch screen operation, real-time monitoring, and automatic fault diagnostics. This reduces operator workload and enhances process reliability.

5. Easy Cleaning and Maintenance

Quick-release parts and transparent front panels allow convenient disassembly and tool-free maintenance. The turret and punching tools are accessible for cleaning, reducing downtime between production runs.

6. Customizable Configuration

The GZPK Series supports a wide range of punch types and tablet sizes, meeting diverse market requirements—from standard round tablets to shaped, embossed, or coated products.

Applications: Designed for Versatile Industrial Use

The GZPK-51/65/83 роторные машины для прессования таблеток serve multiple industries with exacting tablet compression needs:

- Фармацевтические препараты: Prescription drugs, over-the-counter tablets, antibiotics, and controlled-release formulations.

- Nutraceuticals: Vitamin tablets, herbal supplements, mineral formulations, and sports nutrition tablets.

- Food Processing: Instant drink tablets, sweeteners, and flavor tablets.

- Chemicals: Catalysts, detergent tablets, and industrial chemical pellets.

Their adaptability makes these machines an ideal choice for manufacturers seeking to expand production capacity while maintaining uniform quality standards.

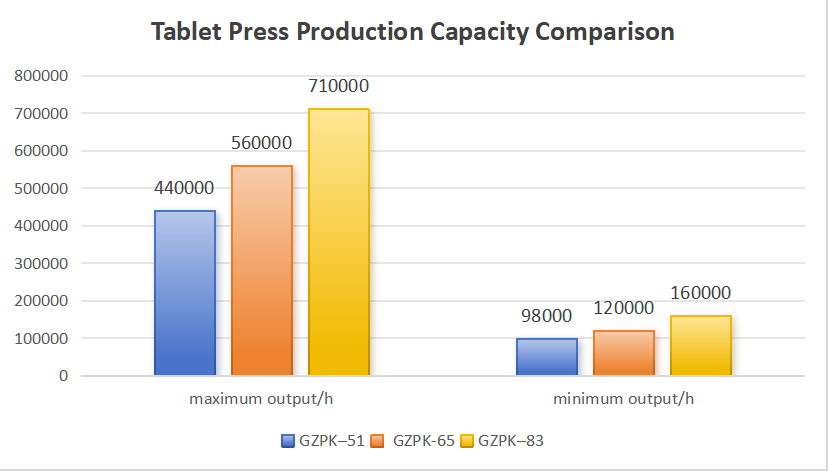

Model Comparison: GZPK-51 vs. GZPK-65 vs. GZPK-83

While all three models share the same superior construction and compression capabilities, their differences lie mainly in tablet output and station quantity:

- GZPK-51: Suitable for medium-scale production, offering balanced speed and flexibility—often used in research and pilot plants.

- GZPK-65: Designed for mid-to-large production volumes; optimal for companies scaling up mass tablet manufacturing.

- GZPK-83: The highest-capacity model, engineered for continuous large-scale industrial production with maximum efficiency and automation level.

Choosing the right model depends on the required output, production line design, and tablet specification. HIJ Machinery’s technical team provides professional consultation to help buyers select the best solution for their pharmaceutical tablet production requirements.

Почему стоит выбрать HIJ Machinery Co., Ltd.

HIJ Machinery Co., Ltd. is a trusted manufacturer with decades of expertise in designing and producing pharmaceutical and packaging machinery. Our product range includes:

- Capsule filling machines

- Tablet press machines (single-punch and rotary type)

- Blister packaging machines

- Cartoning machines

We provide complete GMP-compliant solutions and support OEM / ODM customization for global customers. HIJ Machinery stands for:

- High Quality: Strict material selection and precision manufacturing processes

- Reliable Performance: Proven results in continuous production environments

- Technical Expertise: Professional engineers offering installation and training

- Global Service: Timely support, spare parts supply, and online technical assistance

Conclusion: Your Trusted Partner for High-Speed Tablet Production

For pharmaceutical and nutraceutical manufacturers seeking efficient, reliable, and hygienic tablet production solutions, the GZPK-51/65/83 High-Speed Rotary Tablet Press Machines с сайта HIJ Machinery Co., Ltd. deliver outstanding performance and long-term value.

Their combination of high pressure, precise automation, и GMP-compliant design ensures consistent quality across every tablet produced. Whether you are upgrading your existing tablet line or expanding production capacity, the GZPK Series offers the perfect balance of innovation, reliability, and productivity.

Свяжитесь с HIJ Machinery Co., Ltd. сегодня. to discuss your production requirements or request a detailed quotation.

Our experts will help you select the right rotary tablet press machine solution for your business.

📩 Email: sales@trustarmac.com

📞 Phone:+86 13868822120