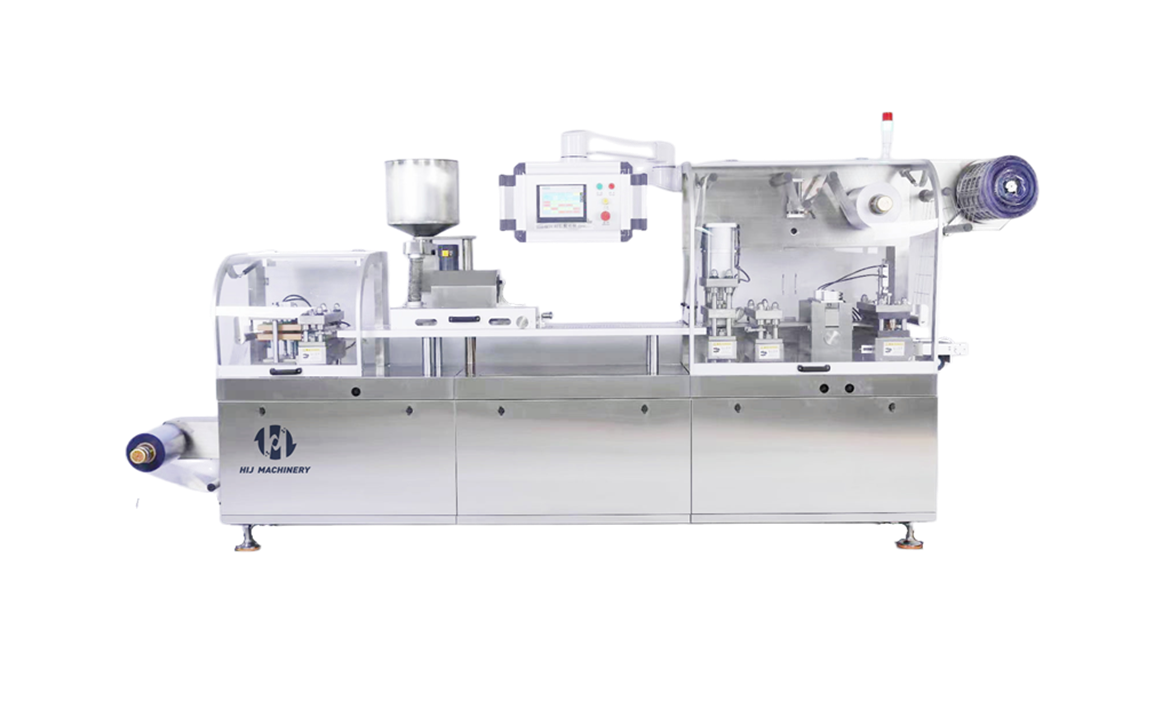

1. What is DPP-260 Blister Packaging Machine?

The DPP-260 is an advanced automatic blister packaging machine designed for packaging products such as capsules, tablets, ampoules, and medical devices into blister packs. This model integrates forming, feeding, sealing, punching, and counting in a single streamlined process, ensuring high efficiency and precise quality control.

Its design meets GMP (Good Manufacturing Practice) standards and is widely used in pharmaceutical manufacturing, healthcare products, and small food items.

High-ranking keywords to include:

- DPP-260 blister packaging machine

- pharmaceutical blister pack equipment

- automatic blister packaging solution

- capsule and tablet packaging machine

2. Technical Features of DPP-260

- High Precision Forming

Utilizes advanced PLC control and servo motors to ensure precise forming of blister cavities. - Versatile Materials

Compatible with PVC, PVDC, ALU foil, PET films, and tropical aluminum. - Stable Production Speed

Capable of up to 6,000 blisters/hour depending on product type and material. - Compact Design

Space-efficient layout suitable for cleanroom environments. - Easy Changeover

Modular tooling system for rapid mold changes between different blister sizes.

3. Applications of DPP-260

- Pharmaceuticals: Capsule, tablet, pill blister packs.

- Medical Devices: Ampoules, syringes, small diagnostic kits.

- Food Industry: Candy, chewing gum, nutritional supplements.

- Consumer Goods: Batteries, small electronics components.

4. Step-by-Step Guide: How to Use the DPP-260

Based on industry experience, here’s the complete operational workflow:

Step 1 – Preparation

- Ensure all materials are available: PVC/PVDC film, aluminum foil, product to be packaged.

- Check the machine’s cleanliness (comply with GMP standards).

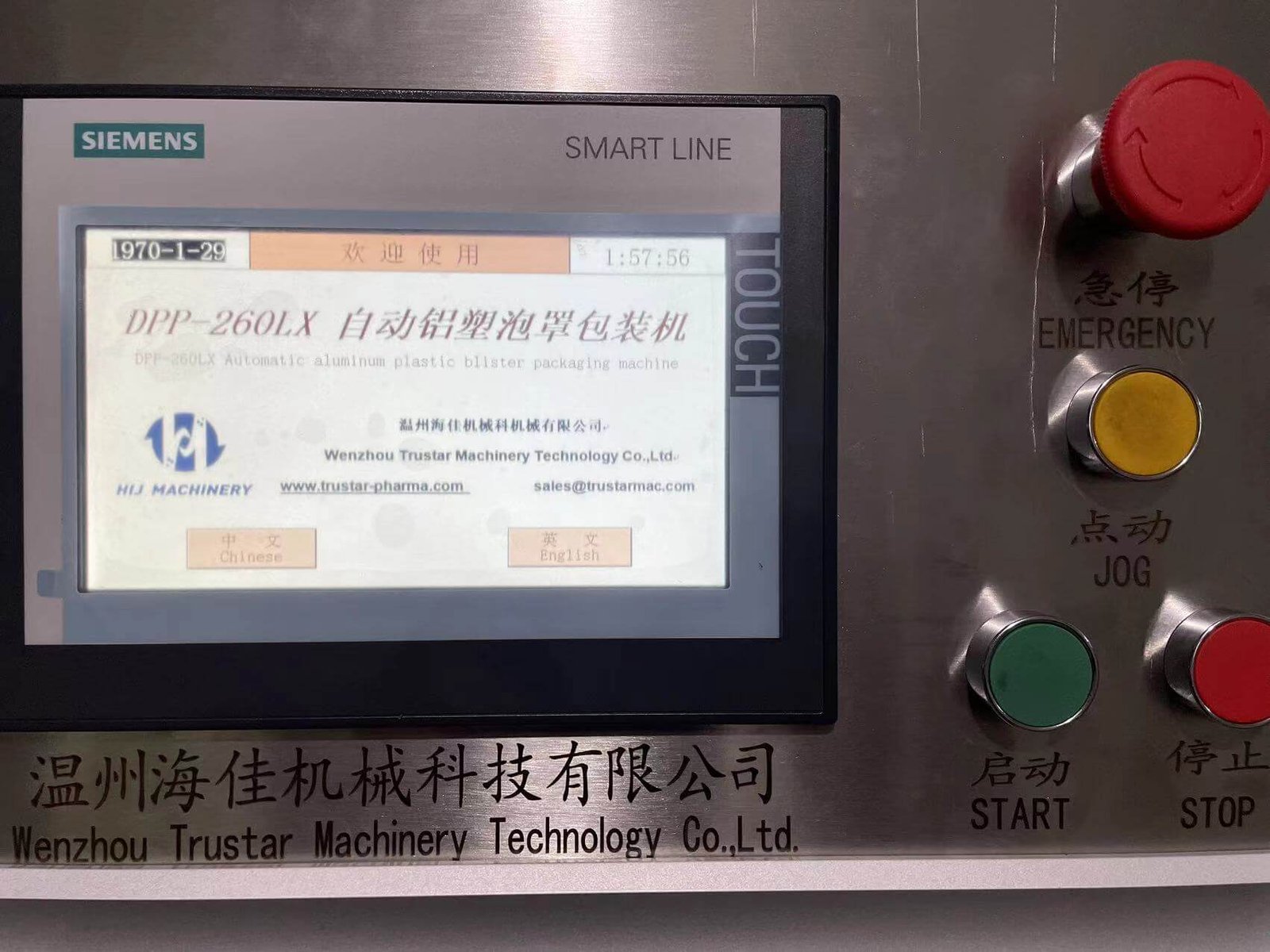

- Power on the machine and inspect pneumatic and electrical connections.

Step 2 – Blister Forming

- Load PVC film onto the forming station.

- The heating plate warms the film to the forming temperature.

- Forming molds create precise cavities according to product size.

Step 3 – Product Feeding

- Use the automatic feeding system (capsule feeder or tablet feeder) to fill cavities.

- Manual feeding can be used for irregular-shaped products.

Step 4 – Sealing

- Aluminum foil is unwound and aligned with the blister sheet.

- Heat-sealing station bonds foil to cavities, ensuring airtight protection.

Step 5 – Cutting & Output

- Punching station cuts the sealed blister packs to the pre-set size.

- Packs are counted automatically and discharged to the output conveyor.

Step 6 – End-of-Run & Cleaning

- Power off the machine.

- Clean all contact parts and tooling.

- Record production data for quality assurance.

5. Safety and Maintenance Tips

- Always follow GMP regulations for hygiene and quality.

- Regularly inspect heating plates and molds for wear.

- Lubricate moving parts according to manufacturer’s schedule.

- Train operators on emergency stops and troubleshooting.

- Store molds properly when not in use to avoid damage.

6. Advantages of Choosing DPP-260

- High-precision production suitable for sensitive products

- Compatible with multiple blister formats and materials

- Easy operation with intuitive touchscreen interface

- Long-term reliability with robust engineering

7. Industry Trends Related to Blister Packaging in 2024

- Smart blister packaging machines with IoT data monitoring

- Eco-friendly blister materials: bio-PVC, recyclable films

- Increased demand from global pharmaceutical markets due to COVID-era focus on packaging safety

- Smaller batch & personalized medicine driving flexible packaging solutions

8. Conclusion

The DPP-260 automatic blister packaging machine offers a complete packaging solution for pharmaceutical, medical, and food products. With high precision, speed, and GMP compliance, it meets the industry’s demand for quality, efficiency, and automated control.

By following this guide and best practices, manufacturers can fully leverage the DPP-260’s capabilities, ensuring reliable production and long-term cost efficiency.