A packaging machine is one of the most critical pieces of equipment in modern manufacturing.

It directly affects product quality, efficiency, cost control, and brand image.

This guide explains everything buyers and engineers search for about packaging machines — in one place.

What Is a Packaging Machine?

A packaging machine is industrial equipment used to pack products into bags, pouches, bottles, boxes, or containers in a consistent and automated way.

Packaging machines are widely used in: • food industry

• pharmaceutical manufacturing

• daily chemical production

• agriculture and pet food

• hardware and industrial goods

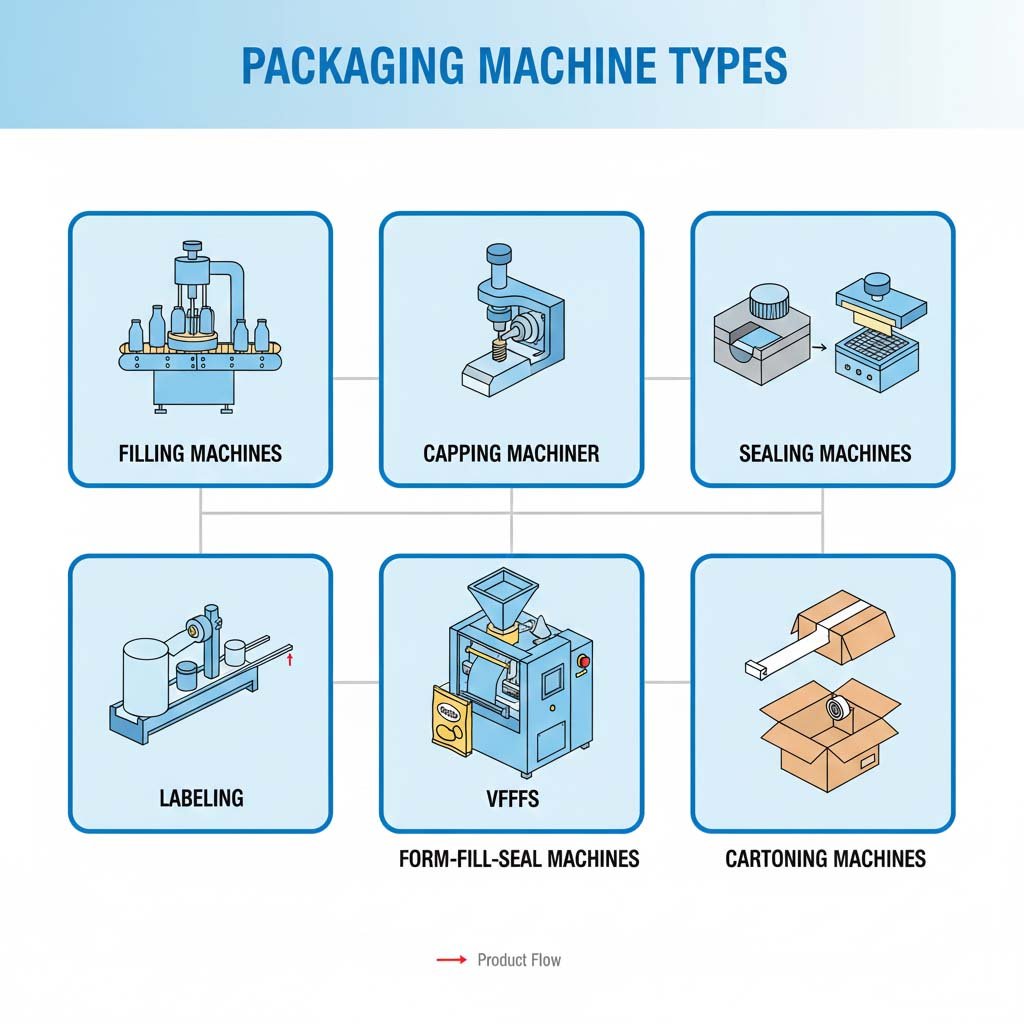

Types of Packaging Machines

This section targets “packaging machine types”

Vertical Packaging Machine

Used for granules, powders, and snacks.

Horizontal Packaging Machine

Ideal for solid items like biscuits and bars.

Pouch Packing Machine

For stand‑up pouches, zipper bags, and doypacks.

Vacuum Packaging Machine

Extends shelf life by removing air.

Filling and Sealing Machine

Used for liquids, pastes, and powders.

Automatic vs Semi‑Automatic Packaging Machines

Automatic packaging machines • high efficiency

• reduced labor cost

• consistent quality

Semi‑automatic packaging machines • lower investment

• flexible operation

• suitable for small batches

Choosing depends on production volume and budget.

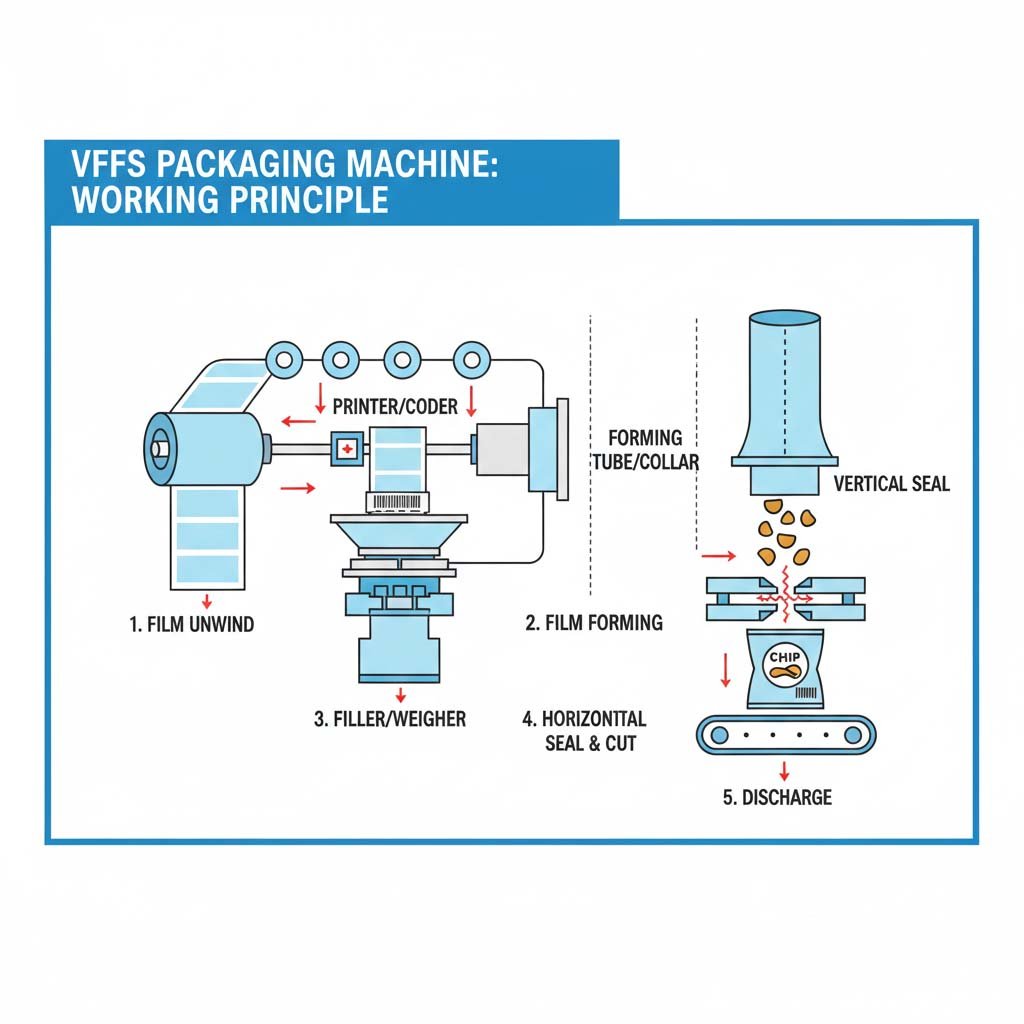

How Does a Packaging Machine Work?

A typical automatic packaging machine works in these steps:

- Product feeding

- Measuring and weighing

- Bag forming or positioning

- Filling

- Sealing

- Cutting and output

Each step affects speed, accuracy, and packaging quality.

Applications of Packaging Machines

Packaging machines are commonly used for:

✅ food packaging machines

✅ coffee and tea packaging

✅ powder and granule products

✅ liquid and paste packaging

✅ pharmaceutical packaging

Different applications require different machine structures and materials.

Packaging Machine Price: What Affects the Cost?

Main price factors include: • machine type

• automation level

• packaging speed

• materials and components

• customization requirements

Low price does not always mean low cost in long‑term operation.

How to Choose the Right Packaging Machine

Before buying a packaging machine, consider: • product characteristics

• packaging format

• required output

• factory space

• local regulations

A professional supplier will ask detailed questions before recommending a solution.

Common Problems in Packaging Machines

• unstable sealing

• inaccurate filling

• film tracking issues

• excessive downtime

Most issues are caused by incorrect machine selection or poor configuration.

Packaging Machine Maintenance and Lifespan

With proper maintenance: • industrial packaging machines can run 8–12 years

• routine inspection reduces downtime

• standardized spare parts improve reliability

Maintenance quality directly affects ROI.

Frequently Asked Questions About Packaging Machines

What is the most common packaging machine?

Vertical form fill seal machines are widely used.

Are packaging machines customizable?

Yes, based on product and packaging needs.

Can one machine pack different products?

With proper configuration, many machines can.

Need Help Choosing a Packaging Machine?

Send us your product and packaging requirements. Our engineers provide technical recommendations within 24 hours.