Description:

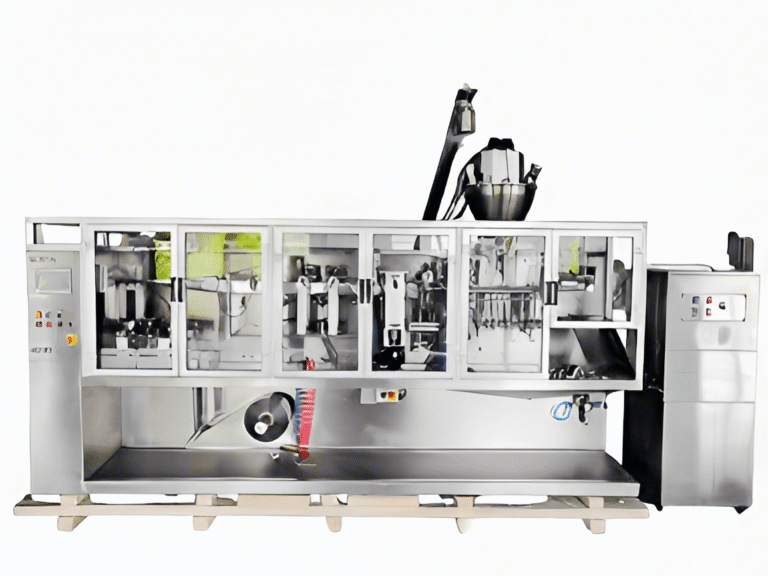

The HS is a compact, high-speed horizontal forming, filling, and sealing machine, designed for efficient small bag packaging. It’s primarily used for filling a variety of products such as coffee, milk powder, sugar, salt, sauces, and even cosmetics like creams, lotions, and hair wax.

This versatile equipment offers multiple filling options and can reach speeds of up to 110 bags per minute. Its sleek design ensures it operates continuously for up to 24 hours with minimal maintenance costs, making it ideal for budget-conscious operations. Additionally, the system can be upgraded to a two-station cutting mode for increased efficiency.

The HS is equipped with a user-friendly control panel and an integrated cabinet, ensuring all electrical controls are housed within the frame. It comes standard with Mitsubishi’s control system, with the option to upgrade to brands like Siemens for enhanced flexibility. This machine is perfect for businesses that require reliable, cost-effective, high-speed packaging solutions.

List of HS Pouch Machine Series Equipment:

| Equipment mode | HS130 | HS160TS | HS160 | HS160D |

| Mini bag size(mm) | 60×80 | 60×80 | 60*80 | 60+60×80 |

| Max bag size(mm) | 140×200 | 140×200 | 180*200 | 90+90×180 |

| Bag volume range | 100ml | 100ml | 400ml | 200ml |

| Production speed PPM | 80 | 50 | 80 | 100 |

| Film size range | Maximum diameter 350 mm, core diameter 76 mm | |||

| Power Consumption | 6.5KW | 7.5KW | 8.0KW | 8.5KW |