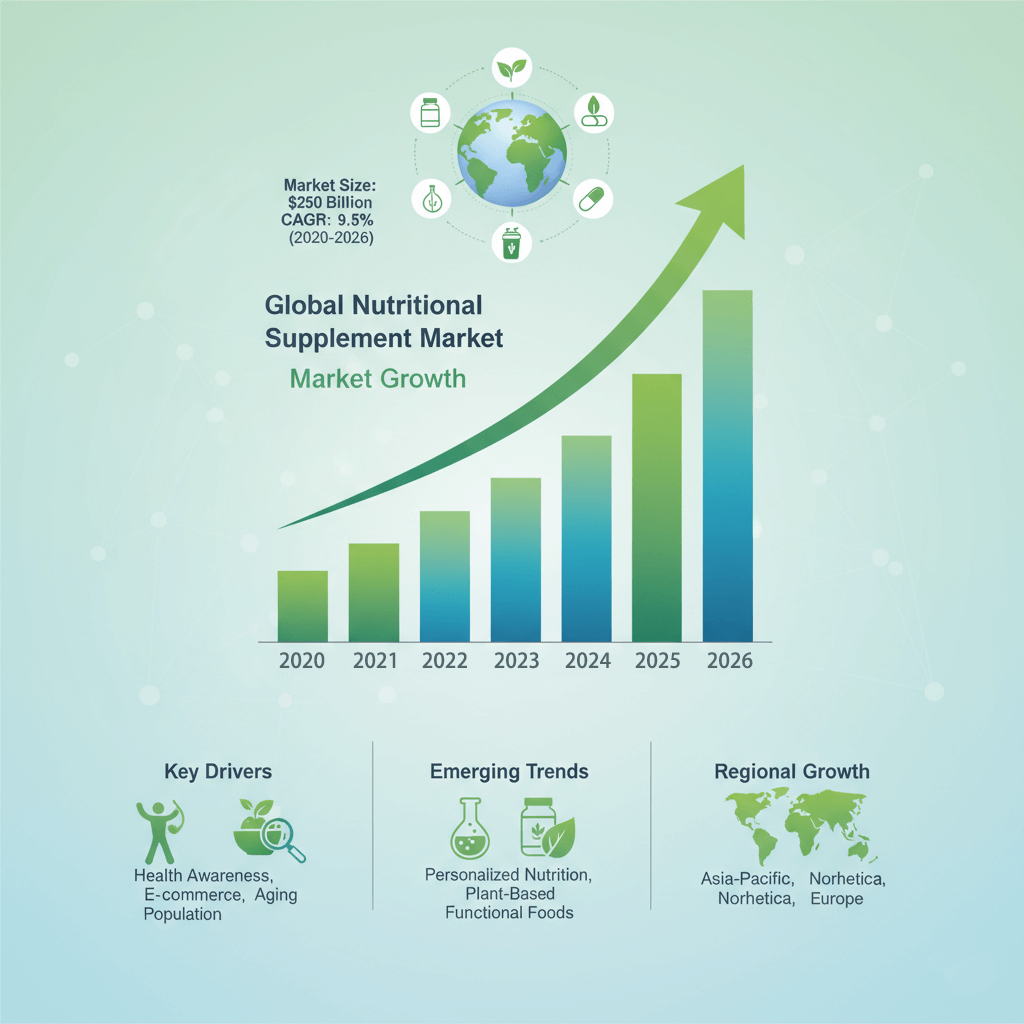

Introduction: Nutraceutical Market Growth and the Role of Capsule Manufacturing

Global demand for nutraceuticals and dietary supplements continues to rise, driven by health-conscious consumers seeking convenient, effective ways to improve their well-being. Capsules — whether hard gelatin, HPMC (vegetable capsules), or other materials — have become a preferred dosage form thanks to their precise dosing, easy swallowing, and ability to mask unpleasant tastes.

For manufacturers, a reliable capsule filling machine is not simply a piece of equipment — it’s the heart of capsule production. Selecting the right model ensures product quality, regulatory compliance, and cost-effective operation. HIJ Machinery Co., Ltd., with decades of experience serving pharmaceutical and nutraceutical industries worldwide, offers advanced solutions tailored to various production needs.

Why Capsule Filling Machines Matter

In international nutraceutical manufacturing, efficiency and accuracy are critical.

- Production Efficiency – Modern capsule filling machines can process tens of thousands of capsules per hour, reducing labor requirements and increasing throughput.

- Dosing Accuracy – High-precision dosing mechanisms ensure each capsule contains the exact intended quantity of active ingredient, vital for consumer safety and regulatory compliance.

- GMP Compliance – Choosing equipment designed according to Good Manufacturing Practice standards minimizes risk of contamination and supports audit readiness.

By investing in a high-quality capsule filling machine, manufacturers improve ROI, maintain consistent product quality, and build customer trust.

Key Considerations When Choosing a Capsule Filling Machine

When selecting a machine, you must look beyond basic specifications and evaluate real-world manufacturing needs.

1. Output and Production Capacity

Assess your current and projected production volumes. For example:

- A small nutraceutical startup might need NJP-400 capacity (around 24,000 capsules/hour).

- Medium-sized operations may choose NJP-800 (around 48,000 capsules/hour).

- Large-scale exporters could require NJP-1200 or higher capacity models.

Choosing a machine that matches your production demand prevents bottlenecks and excessive downtime.

2. Capsule Types and Sizes

Capsule filling machines can handle a variety of capsule sizes — from 00 (largest) to 5 (smallest). Determine:

- Your preferred capsule material (gelatin or HPMC for vegetarian markets).

- Whether you need change parts for multiple sizes, which allows product diversification without buying multiple machines.

3. Material Compatibility: Powder, Granule, Pellet

Not all active ingredients have the same flow characteristics. Some are fine powders, some are coarse granules, and some require pellets for extended release. A compatible machine must:

- Offer adjustable dosing mechanisms.

- Prevent dust generation that may affect operator safety or product quality.

HIJ Machinery designs capsule filling machines with multiple dosing options to suit powders, granules, and pellets.

4. Automation Level and Cleaning Requirements

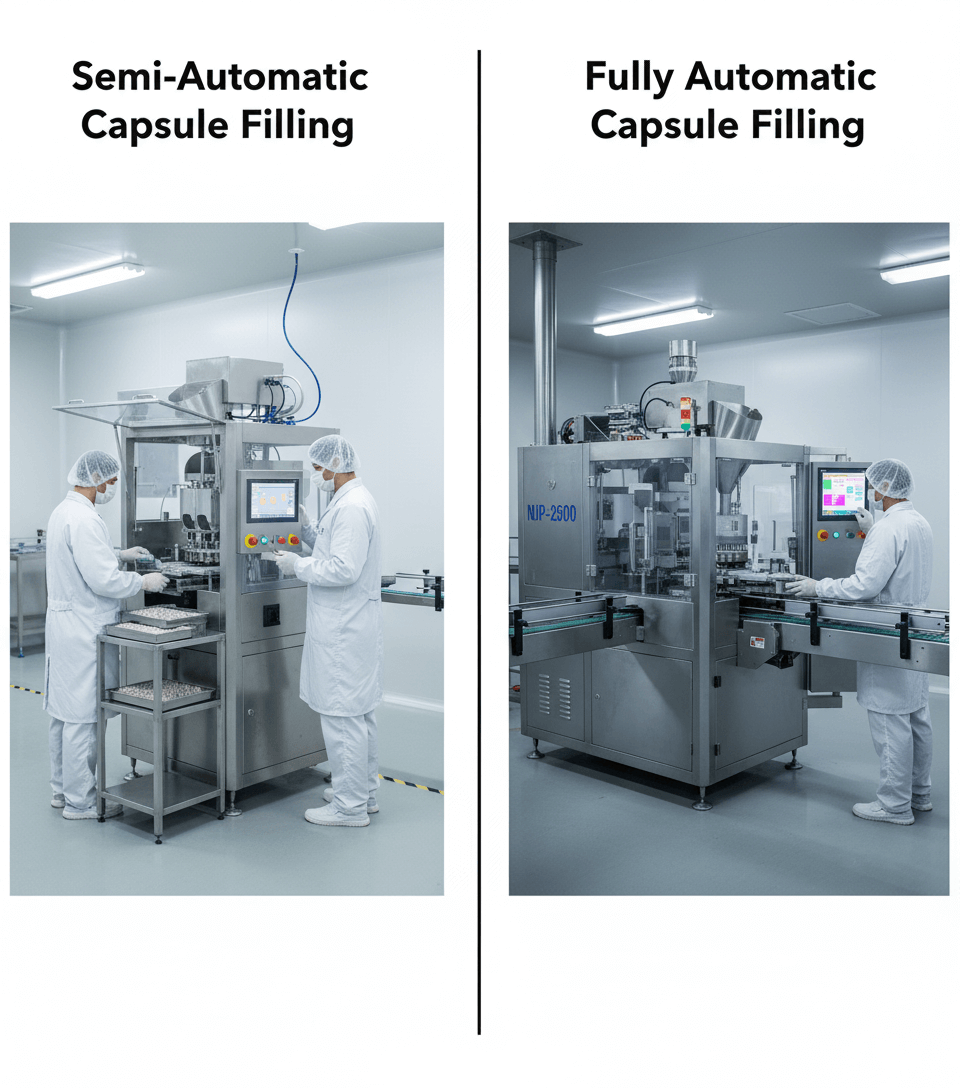

Evaluate labor costs and operator skills available in your facility:

- Semi-automatic machines require more operator involvement but are ideal for smaller batches.

- Fully automatic models minimize human contact, enhance GMP compliance, and reduce contamination risk.

Cleaning is equally critical — machines with modular design and easy disassembly save time during batch changeovers.

Types of Capsule Filling Machines

Semi-Automatic Capsule Filling Machines

Pros: Lower initial investment, good for R&D or pilot production, flexible operation.

Cons: Lower output, higher labor requirement, increased risk of human error.

Fully Automatic Capsule Filling Machines

Pros: High-speed production, consistent quality, less operator intervention, suitable for high-volume exports.

Cons: Higher purchase price, requires trained personnel for maintenance.

Choosing the Right Model for Your Business

HIJ Machinery Co., Ltd. offers several models to meet diverse production requirements:

- NJP-400 – Compact design, 24,000 capsules/hour, ideal for small to medium-scale nutraceutical manufacturing or specialty product lines.

- NJP-800 – Balanced performance, 48,000 capsules/hour, suits growing companies expanding their product range.

- NJP-1200 – High-output model, up to 72,000 capsules/hour, built for large-scale continuous production with export-oriented capacity.

Each model features stainless steel construction, advanced vacuum positioning systems, and precise dosing technology for maximum efficiency.

| Item | Unit | NJP-200 | NJP-400 | NJP-800 | NJP-1200 | NJP-2500 |

|---|---|---|---|---|---|---|

| Production Capacity (approx.) | pcs/hour | 20,000–40,000 | 40,000–60,000 | 60,000–100,000 | 100,000–150,000 | 200,000–300,000 |

| Working Stations | slots/channels | 4 | 8 | 16 | 24 | 48 |

| Capsule Size Range | size | 000#–5# (customizable) | 000#–5# (customizable) | 000#–5# (customizable) | 000#–5# (customizable) | 000#–5# (customizable) |

| Filling Range (powder/granule) | mg | 10–500 | 20–800 | 50–1,000 | 50–1,500 | 50–3,000 |

| Filling Accuracy (depends on formulation & metering type) | ± | ±2%–5% | ±2%–4% | ±1%–4% | ±1%–3% | ±1%–3% |

| Dosing System | — | Piston/rotary doser | Piston or servo dosing (optional) | Piston or servo auger | High-precision servo dosing | High-speed servo/auger dosing |

| Machine Dimensions (L×W×H) | mm | 1,100×800×1,600 | 1,300×900×1,700 | 1,800×1,200×1,900 | 2,200×1,300×2,000 | 2,800×1,600×2,200 |

| Machine Weight | kg | ≈450 | ≈650 | ≈1,050 | ≈1,400 | ≈2,200 |

| Power Supply | V / Hz | 380V / 50Hz, 3-Phase | 380V / 50Hz, 3-Phase | 380V / 50Hz, 3-Phase | 380V / 50Hz, 3-Phase | 380V / 50Hz, 3-Phase |

| Total Power | kW | 1.5 | 2.2 | 3.0 | 4.0 | 6.0 |

| Air Supply | MPa (requirement) | 0.6–0.8 MPa; ≥0.4 m³/min | 0.6–0.8 MPa; ≥0.6 m³/min | 0.6–0.8 MPa; ≥0.8 m³/min | 0.6–0.8 MPa; ≥1.0 m³/min | 0.6–0.8 MPa; ≥1.5 m³/min |

| Hopper Capacity | L | 20 | 40 | 80 | 120 | 200 |

| Machine Material | — | SUS304 stainless steel (contact parts) + coated steel frame | SUS304 stainless steel | Full SUS304 stainless steel | Full SUS304 stainless steel | Full SUS304 stainless steel |

| Control System | — | PLC + 7″ touchscreen | PLC + 7″/10″ touchscreen | PLC + 10″ touchscreen (Ethernet optional) | Advanced PLC + 10″ touchscreen | Industrial PLC + large touchscreen, recipe management |

| HMI Functions | — | Parameter setting, counting, fault display | Recipe storage, remote diagnostics (optional) | Recipe management, batch tracking | Statistics report, remote maintenance | Full monitoring, MES interface (optional) |

| Safety/Inspection Functions | — | Capsule shortage stop, counter | Material shortage/blockage alarm | Metal detector (optional), leakage detection | Auto rejection, defect statistics | Online weighing/shape detection, rejection, data logging |

Maintenance and Operation Tips

To keep your capsule filling machine running at peak performance:

- Routine Cleaning – Clean contact parts between batches to prevent cross-contamination.

- Lubrication – Follow manufacturer guidelines for lubricating moving components.

- Operator Training – Ensure all operators understand setup, troubleshooting, and safety protocols.

- Spare Parts Management – Keep essential spare parts on hand to avoid unexpected downtime.

- Preventive Maintenance – Schedule inspections to identify wear and replace components before failures occur.

Conclusion & Call to Action

A well-chosen capsule filling machine can transform your nutraceutical production line, delivering higher efficiency, consistent quality, and compliance with global industry standards. Whether you are producing herbal supplements, sports nutrition products, or functional vitamins, HIJ Machinery Co., Ltd. offers a full range of capsule filling solutions backed by OEM/ODM support and global service.

📩 Contact HIJ Machinery Co., Ltd. today to discuss your production needs, get expert technical recommendations, and request a quotation. With our experience in capsule filling, blister packaging, and cartoning machines, we are ready to help you achieve your manufacturing goals.