Introduction

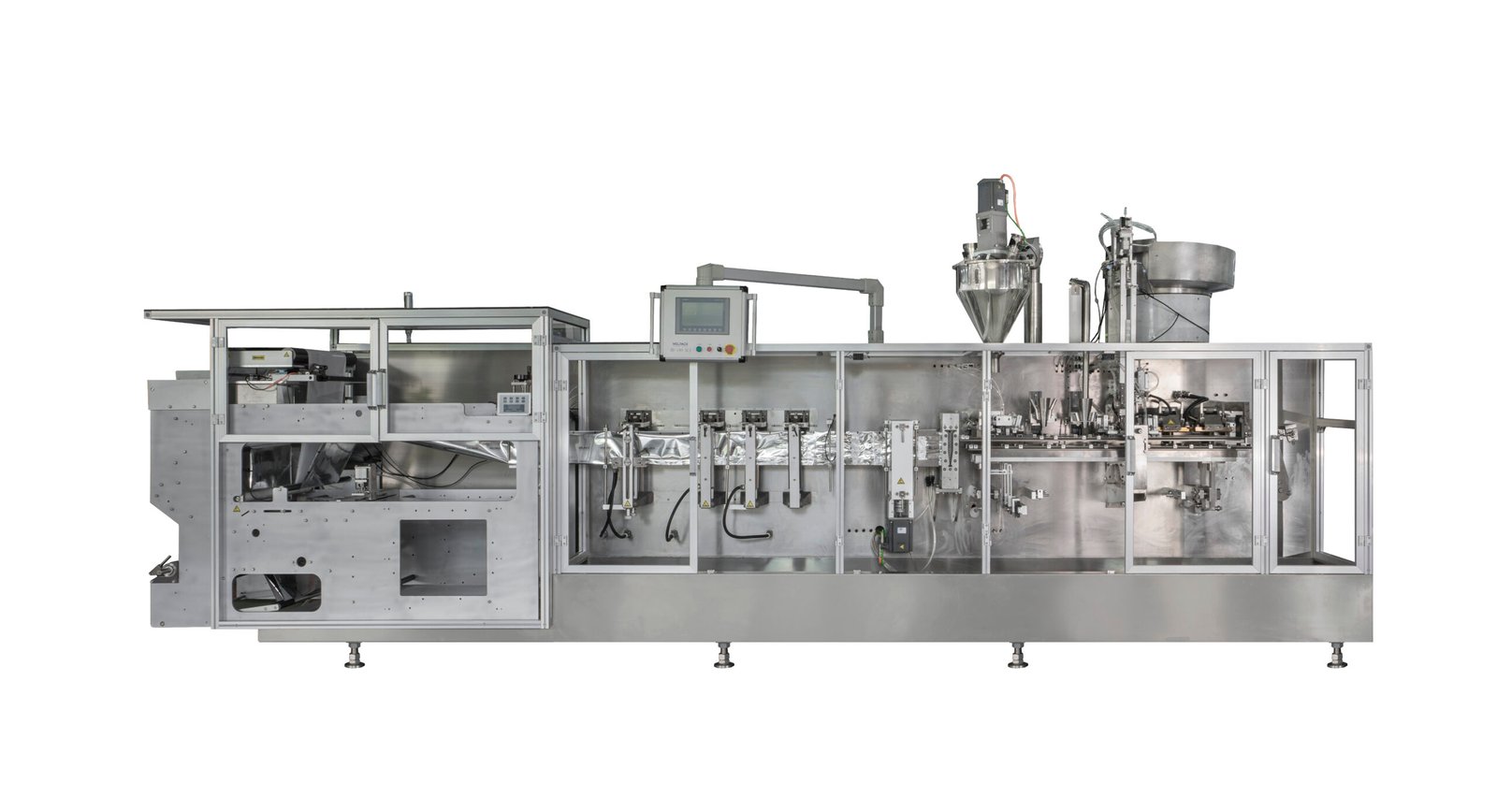

In the past two decades, the global demand for flexible packaging has grown rapidly across the pharmaceutical, nutraceutical, food, and chemical industries. As manufacturers increase their production capacity and pursue higher automation, the doypack packaging machine has become one of the most essential pieces of equipment in modern factories.

With over 20 years of experience in powder, liquid, granule, and paste packaging lines, I have seen how the right machine can significantly improve efficiency—and how a poor choice can create long-term operational problems.

This article explains the key challenges buyers face, the engineering principles behind vertical and horizontal doypack systems, practical cases from real customers, and the advantages of HIJ Machinery’s HMK-1600, HMK-2000, and HMK-2600 series. It concludes with practical recommendations to help you select the right machine for your production needs.

Market Challenges and Common Customer Problems

1. Increasing global demand for flexible packaging

More brands are shifting from rigid packaging (bottles, jars) to flexible pouches due to:

-

Lower material cost

-

Better transportation efficiency

-

Enhanced shelf presentation

-

Convenience for consumers

2. Common pain points faced by packaging factories

From my on-site experience, manufacturers often encounter these issues:

-

Insufficient packaging speed → limits daily output

-

Unstable sealing quality → causes leakage, returns, or customer complaints

-

Complicated film replacement → increases downtime

-

Difficult-to-clean machine structure → fails GMP or food safety audits

-

Unstable pneumatic systems → inconsistent filling or sealing

-

Budget limitations vs high configuration expectations

These problems occur not because customers lack knowledge, but because choosing the wrong machine—or wrong configuration—forces them into long-term compromises.

Technical Analysis: What Buyers Must Understand

1. Different doypack packaging technologies

The industry mainly uses:

-

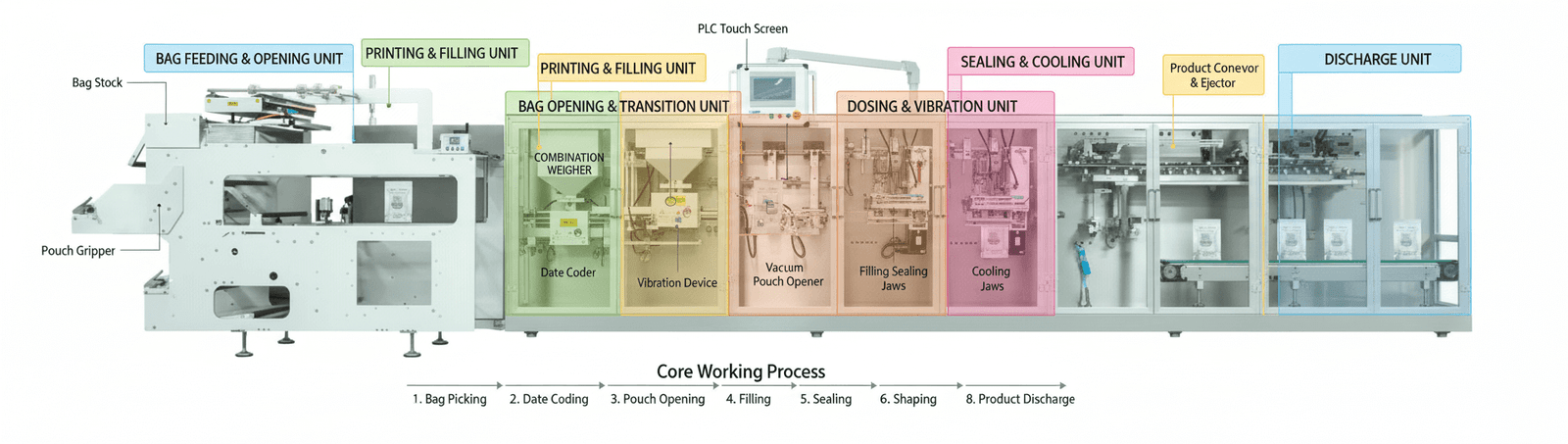

HFFS (Horizontal Form-Fill-Seal)

-

Suitable for powders, granules, liquids, paste, and mixed products

-

High speed, high stability

-

Multi-station operation with strong sealing strength

-

-

Premade pouch machines

-

Good for small-batch or multiple pouch sizes

-

Faster changeover

-

Lower investment cost

-

HIJ’s HMK series belongs to HFFS, which is the preferred solution for medium to large production capacity.

2. How machine parameters affect production

Key technical specifications buyers should evaluate:

-

Maximum output (PPM)

-

Pouch width and height range

-

Sealing temperature control

-

Compatibility with different films (PET/PE, ALU/PE, Kraft, etc.)

-

Filling accuracy

-

Vacuum or nitrogen flushing options

-

Cooling station design (for liquids/paste sealing)

For example, a poor-quality sealing system can cause:

-

Micro leaks

-

Weak seals

-

Burnt film

-

Bag deformation

This directly affects your brand reputation and consumer trust.

3. How to judge whether a packaging machine is reliable

A truly professional HFFS machine should include:

-

High-precision servo system

-

Stable temperature control

-

Reinforced sealing jaws

-

Easy-cleaning stainless steel structure

-

Simple film threading and replacement

-

Good accessibility for maintenance

-

Safety protection and interlocks

These are engineering standards—not marketing claims.

Real Applications & Customer Cases

Case 1: Coffee powder manufacturer in the United States

Problem: Sealing leakage and pouch deformation

Solution: We redesigned their seal pressure and added a temperature compensation system.

Result: Customer reduced rejection rate from 4.8% to 0.6% within one week.

Case 2: Sauce producer in Vietnam

Problem: Low speed and heavy dripping

Solution: Upgraded anti-drip nozzles + optimized filling pressure.

Result: Production speed increased by 30% without additional operators.

Case 3: Juice manufacturer in Saudi Arabia

Problem: Small pouch sealing inconsistent due to liquid contamination on seal area

Solution: Added a double-cleaning mechanism and modified sealing structure.

Result: 24/7 production with near-zero leakage.

Advantages of the HMK-1600 / HMK-2000 / HMK-2600 Series

Based on engineering standards, not marketing language.

1. Automatic and high efficiency

-

Designed for continuous, high-speed production

-

Multi-station servo control ensures stable timing and movement

2. Stable, durable, long service life

-

304/316 stainless steel contact parts

-

Reinforced frame for vibration-free performance

-

Temperature-controlled sealing system

3. Not film-sensitive

Works with:

-

PET/PE

-

OPP/CPP

-

ALU laminated film

-

Kraft paper film

4. Anti-drip upgraded filling system

Especially useful for:

-

Sauces

-

Oils

-

Juices

-

Creams and cosmetic liquids

5. Safety-first design

-

Magnetic safety doors

-

Emergency stops

-

Alarm diagnostics

-

Overload protection

6. Reduced labor cost

-

Fully automatic operation

-

Simple film loading

-

Shorter changeover time

7. OEM / ODM service available

-

Custom pouch shapes

-

Multi-lane filling

-

Integration with upstream or downstream equipment

Frequently Asked Questions (FAQ)

1. Can the machine reach the speed you advertise?

Yes—speed depends on pouch size, filling material viscosity, and sealing temperature.

We test actual samples before confirmation.

2. Can the machine handle our pouch size?

HMK series covers a wide range. If needed, we can customize forming molds.

3. What if our budget is limited but we want a high-end configuration?

We provide flexible configurations. Servo systems, filling types, and stations can be upgraded gradually.

4. How long can the machine run per day?

Normally 20–24 hours with proper maintenance.

5. Is training included?

Yes—online and on-site training available.

Conclusion & Purchase Recommendations

Choosing the right doypack packaging machine is not about buying the most expensive model—it is about selecting a system that matches your material, output, pouch size, and future growth plan.

Recommended matching strategy:

-

HMK-1600 → For small/medium factories, 20–40 ppm

-

HMK-2000 → For medium capacity, 40–60 ppm

-

HMK-2600 → For high-output mass production, 60–80+ ppm

If you are unsure which model fits your needs, prepare these data:

-

Product type (powder, liquid, granule, paste)

-

Viscosity or flowability

-

Pouch dimensions

-

Expected speed

-

Film type

-

Budget range

Send these details to HIJ Machinery, and we will offer a precise recommendation based on engineering experience.