Introduction Wet wipes are in high demand across baby care, personal hygiene, cosmetics, and healthcare. For manufacturers and exporters, the right wet wipes packaging machine directly impacts product quality, output, compliance, and cost efficiency. This guide explains how wet wipes are made, how packaging works, typical machine costs , and what to consider when choosing equipment for different formats such as baby wipes and individually wrapped wet wipes.

What Are Wet Wipes and How Are They Made? Understanding how wet wipes are manufactured helps you choose the right packaging solution later.

How are wet wipes manufactured?

- Substrate: Nonwoven fabric (spunlace is common) unwound, inspected, and tension-controlled.

- Folding and stacking: The web is slit and folded into Z- or C-folds, then counted into stacks for canisters or soft packs.

- Lotion application: Precise dosing of a water-based solution containing humectants, mild surfactants, preservatives, and skin-friendly additives. Inline metering keeps saturation uniform.

- Cutting: Rotary knives or guillotine cutting set the wipe length and count per pack.

- Packaging: Stacks are transferred to primary packaging—flow packs, canisters, or single sachets—then sealed.

- Coding and inspection: Date codes/lot codes are printed; vision systems check seal integrity and count accuracy.

- Secondary packaging: Cartoning, case packing, and palletizing for shipment.

How to Make Wet Wipes Packaging: Formats and Systems Your packaging choice depends on market, shelf-life, and distribution.

Common formats:

- Soft flow packs (10–100+ wipes): Resealable label or rigid flip-top lid for baby wipes and personal care.

- Canisters/tubs (60–200 wipes): Common for household and surface disinfecting wipes.

- Individually wrapped wet wipes (single pack): Single sachet wet wipes machine lines produce travel and on-the-go wipes for hospitality, airlines, and cosmetics.

- Wet tissue single pack: Similar to single sachets; focus on tight seal and compact size.

Key packaging steps:

- Product infeed and stacking: From the converting unit, stacks are synchronized to the wrapper.

- Film handling: Printed film is formed into a pouch; registration marks align graphics and zippers or peel labels.

- Lotion balance: Some lines add top-up dosing in-pack to maintain target moisture.

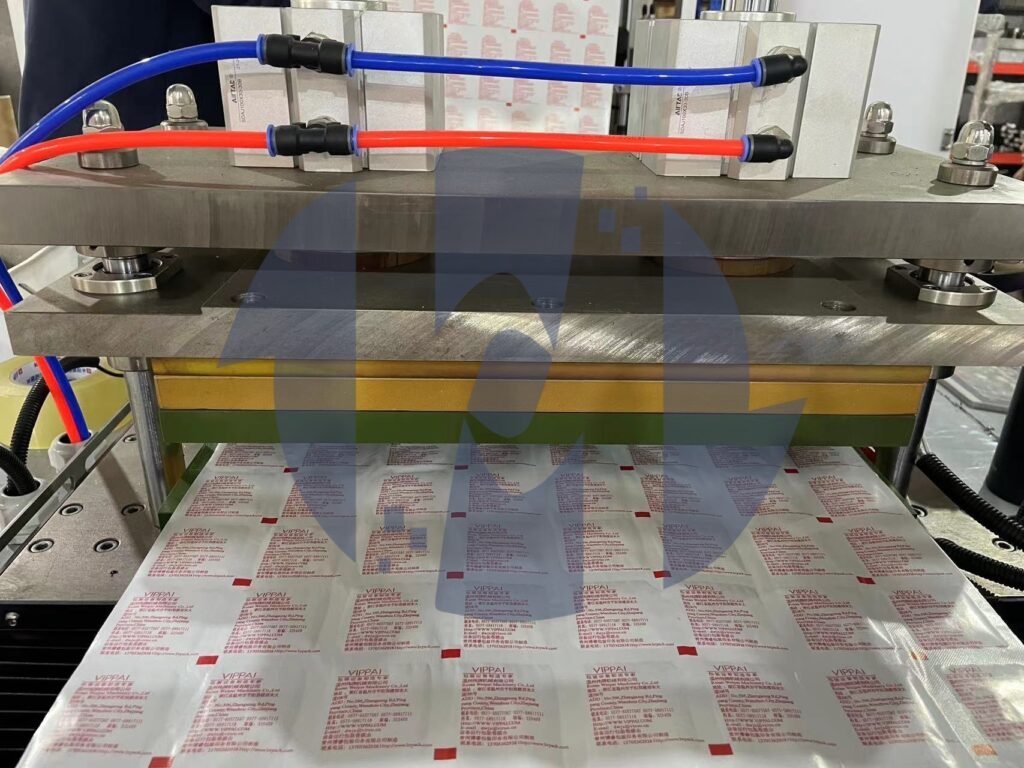

- Sealing: Heat or ultrasonic sealing for flow packs; high-integrity seals are critical for moisture retention.

- Labeling and lidding: Apply reseal labels or assemble flip-top lids with hot-melt.

- Coding and QA: Print date/lot codes; test for seal strength, leakage, and pack weight.

- Cartoning/case packing: Automated end-of-line improves throughput and reduces labor.

What Is the Cost of a Wet Wipes Manufacturing Machine? (USD) Costs vary by capacity, automation level, and format. Below are typical price bands to help budgeting. Actual quotes will depend on options like servo control, vision inspection, and stainless-steel grades.

- Entry-level wet wipes making and packaging line (semi-automatic, 60–120 packs/min): USD 35,000–90,000

- Mid-range automatic line (120–250 packs/min, soft packs): USD 90,000–250,000

- High-speed line (250–500+ packs/min, advanced servo, auto splicing, lid applicator): USD 250,000–650,000

- Baby wipes making machine (soft packs with flip-top lids, 56–100 sheets): USD 120,000–380,000 depending on speed and lid station

- Single sachet wet wipes machine (individually wrapped): USD 18,000–80,000 depending on lanes (1–8 lanes) and speed

- Canister/tub line (rewinder + slitter + canister loader + capper): USD 200,000–700,000

Operating cost factors:

- Nonwoven substrate and film cost per pack

- Lotion/concentrate and preservative cost

- Energy consumption (kWh) and compressed air demand

- Changeover time and labor

- Scrap rate (web breaks, mis-seals)

- Maintenance and spare parts

How to Choose the Right Wet Wipes Packaging Machine Consider these criteria to ensure performance and ROI:

- Product type: Baby wipes vs disinfecting vs cosmetic. Lotion viscosity, alcohol content, and preservative system affect materials and seals.

- Format: Soft pack, canister, or individually wrapped wet wipes. Choose flow packer, canister loader, or sachet machine accordingly.

- Capacity: Align with demand; avoid overbuying speed you won’t use. Plan for peak loads and future expansion.

- Material compatibility: Film (PE/PP/CPP/laminates) and label adhesives; verify seal window and peel strength.

- Moisture retention: Seal integrity, film WVTR/OTR specs, and reclose label quality.

- Hygiene design: Stainless steel (SS304/SS316), easy-clean guards, CIP for lotion tanks, HEPA-filtered enclosures.

- Automation and changeover: Recipe management, servo axes, tool-less change parts, auto splicing for film and nonwoven.

- Quality control: Vision inspection, weight check, seal testers, inline leak detection.

- Compliance: CE/UKCA, UL, GMP documentation; for disinfectants, regulatory validation and traceability.

- After-sales service: Availability of local technicians and spare parts.

Quality and Testing Checklist

- Sheet count accuracy within tolerance

- Uniform lotion distribution and target weight per pack

- Seal strength tests (ASTM F88) and burst/leak tests

- Microbial testing of lotion and finished goods (per ISO standards)

- Aging/shelf-life testing: moisture loss over time under different climates

- Packaging print and registration accuracy

Frequently Asked Questions How are wet wipes made? Nonwoven fabric is folded, saturated with a precisely metered lotion, cut to length, then packaged in soft packs, canisters, or single sachets before coding and case packing.

How to make wet wipes packaging? Use a flow packer for soft packs, a canister line for tubs, or a single-sachet wet wipes machine for individually wrapped wipes. Ensure correct film selection, seal integrity, and reclose label or lid application.

What is the cost of wet wipes manufacturing machine? Entry systems start around USD 35,000–90,000, mid-range lines run USD 90,000–250,000, and high-speed or specialized lines (baby wipes with lid applicators or multi-lane sachet machines) can reach USD 250,000–650,000+.

Call to Action Looking to source a wet wipes packaging machine or upgrade your line? Contact us for a tailored recommendation on baby wipes, soft packs, or single-sachet systems, including capex/opex modeling and supplier comparisons.