Background

In modern pharmaceutical manufacturing, continuous and stable production is essential to meet GMP standards and minimize material loss. Capsule products, due to their dosage precision requirements and powder flow complexity, demand high equipment accuracy and automation. The HMK series capsule filling machine has been widely accepted in pharmaceutical enterprises for these reasons. As an engineer with over a decade of experience in capsule filling systems, I will analyze this series’ mechanical and process advantages from a technical standpoint, rather than a promotional one.

Fundamental Principles

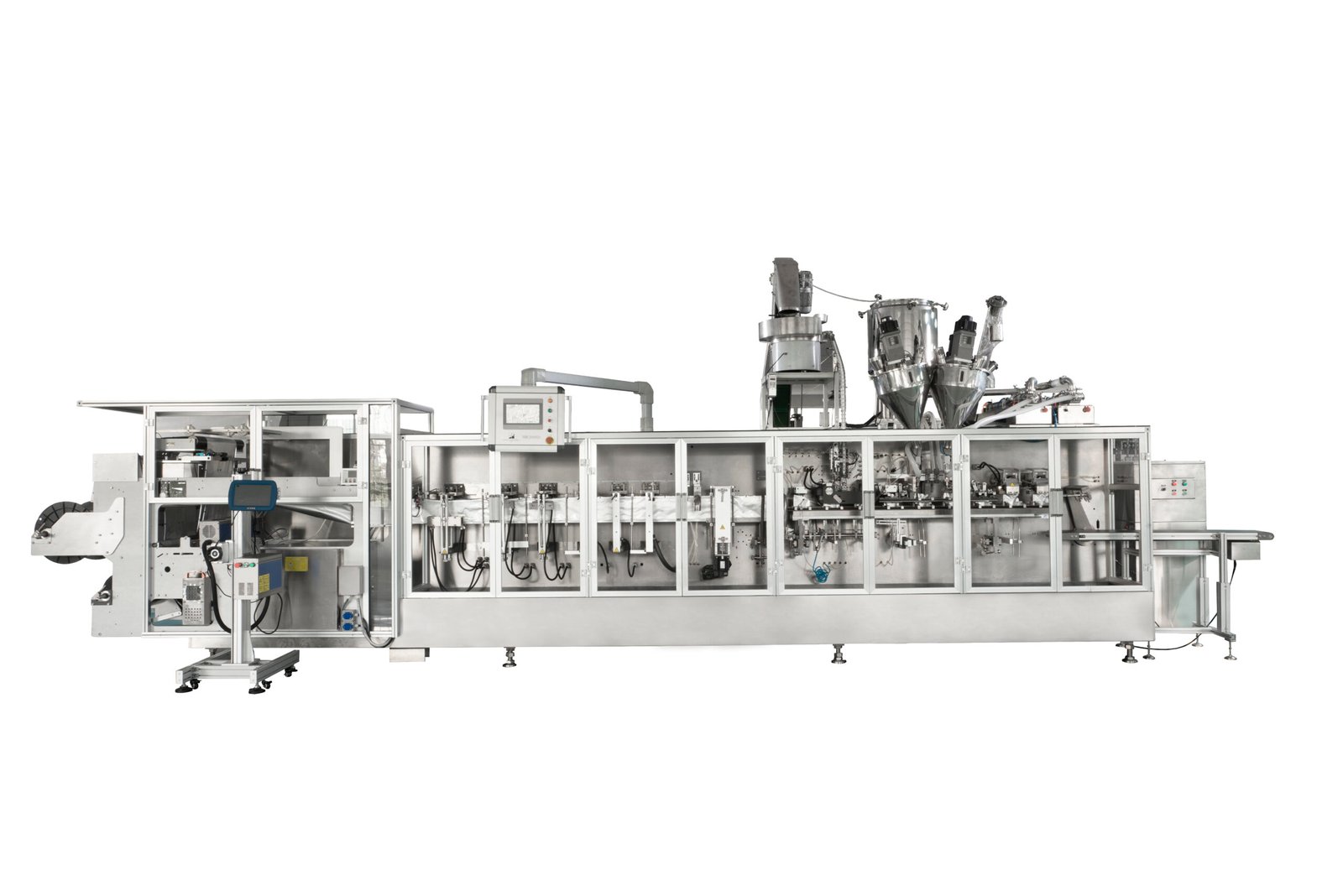

A capsule filling machine operates by transferring powder or pellets into capsule bodies under controlled volume and pressure. The process typically involves several key units:

- Feeding System – responsible for powder delivery and consistency.

- Dosing Disc & Metering Mechanism – defines each capsule’s fill weight.

- Capsule Alignment & Closing Station – ensures sealing precision.

- Vacuum and Pneumatic System – maintains capsule body positioning and reduces powder loss.

The HMK series and similar automatic capsule machines integrate these subsystems under continuous servo-controlled motion, ensuring uniform filling and real-time correction during production.

Engineering Analysis

1. Powder Characteristics and Dosing Accuracy

Pharmaceutical powders vary in density, flowability, and humidity sensitivity. Poor flow can cause inconsistent capsule fill weights. The HMK series incorporates an optimized metering disk structure and anti-adhesion surface treatment, improving powder transport and reducing caking.

The dosing disk uses precision-ground stainless-steel surfaces (flatness < 0.01 mm) to maintain consistent volumetric pockets. Combined with a servo-driven dosing cam, the system minimizes fill weight deviation—even when powder flow properties fluctuate.

2. Mold Precision and Stability

In capsule machines, mold accuracy determines capsule alignment, sealing quality, and mechanical wear. HMK series molds are machined on five-axis CNC centers with position tolerances under ±0.005 mm. This high precision ensures smooth rotation and long-term stability during continuous operation.

Additionally, the modular turret structure isolated from vibration sources improves dynamic balance, reducing stress on bearings and mechanical seals.

3. Vacuum Suction and Capsule Orientation

Capsule separation relies on vacuum suction—the system must stabilize the capsule body without damaging soft gelatin walls. HMK’s multi-channel vacuum distribution avoids excessive airflow and provides separate control for each station. This fine-grained vacuum management allows accurate capsule orientation during high-speed cycles (>90,000 capsules/hour) while maintaining GMP cleanliness and minimizing dust.

4. Automated Feeding and Continuous Production Logic

Traditional manual feeding often leads to inconsistent powder supply and downtime for refilling. HMK automatic feeding systems include real-time powder level sensors and closed-loop vacuum transfer lines, which stabilize powder flow and prevent material contamination.

The system continuously feeds material without halting production, enabling true continuous batch operation—critical for modern pharmaceutical plants adopting PAT (Process Analytical Technology) systems.

Engineering Solutions and Recommendations

- Powder Pre-treatment: Ensure powder moisture <3% and uniform granulation size (120–200 mesh) to improve dosing stability.

- Regular Mold Calibration: Use laser alignment tools weekly to maintain mechanical tolerance and reduce capsule loss.

- Vacuum Line Inspection: Check vacuum pressure and filter integrity daily to avoid capsule body deformation.

- Servo System Tuning: Adjust turret acceleration profiles to reduce vibration and powder spillage during high-speed cycles.

- Material Traceability Integration: Connect the automatic capsule machine’s data output to MES for continuous GMP validation.

Summary

From an engineering perspective, the HMK series capsule filling machine stands out for continuous pharmaceutical production because of its mechanical precision, stable powder handling, and automation design. The synergy of optimized dosing disks, high-precision molds, multi-channel vacuum systems, and intelligent feeding lines ensures both efficiency and GMP compliance.

Implementing this system allows pharmaceutical enterprises to achieve stable, scalable production while maintaining strict quality standards. For engineers, its design philosophy also provides a clear example of how mechanical precision supports process integrity in the pharmaceutical domain.