In the pharmaceutical and manufacturing industries, efficiency is everything. However, even the most experienced operators encounter issues like tablet capping, sticking, ou weight variation. These defects not only waste raw materials but can also halt your entire production line.

Em Maquinaria Hijm, we have spent over 20 years not just manufacturing tablet press machines, but also helping our clients optimize their production. We know that often, the difference between a rejected batch and a perfect one lies in technical adjustments.

Here is our technical guide to troubleshooting the most common prensa para comprimidos issues, and how to prevent them.

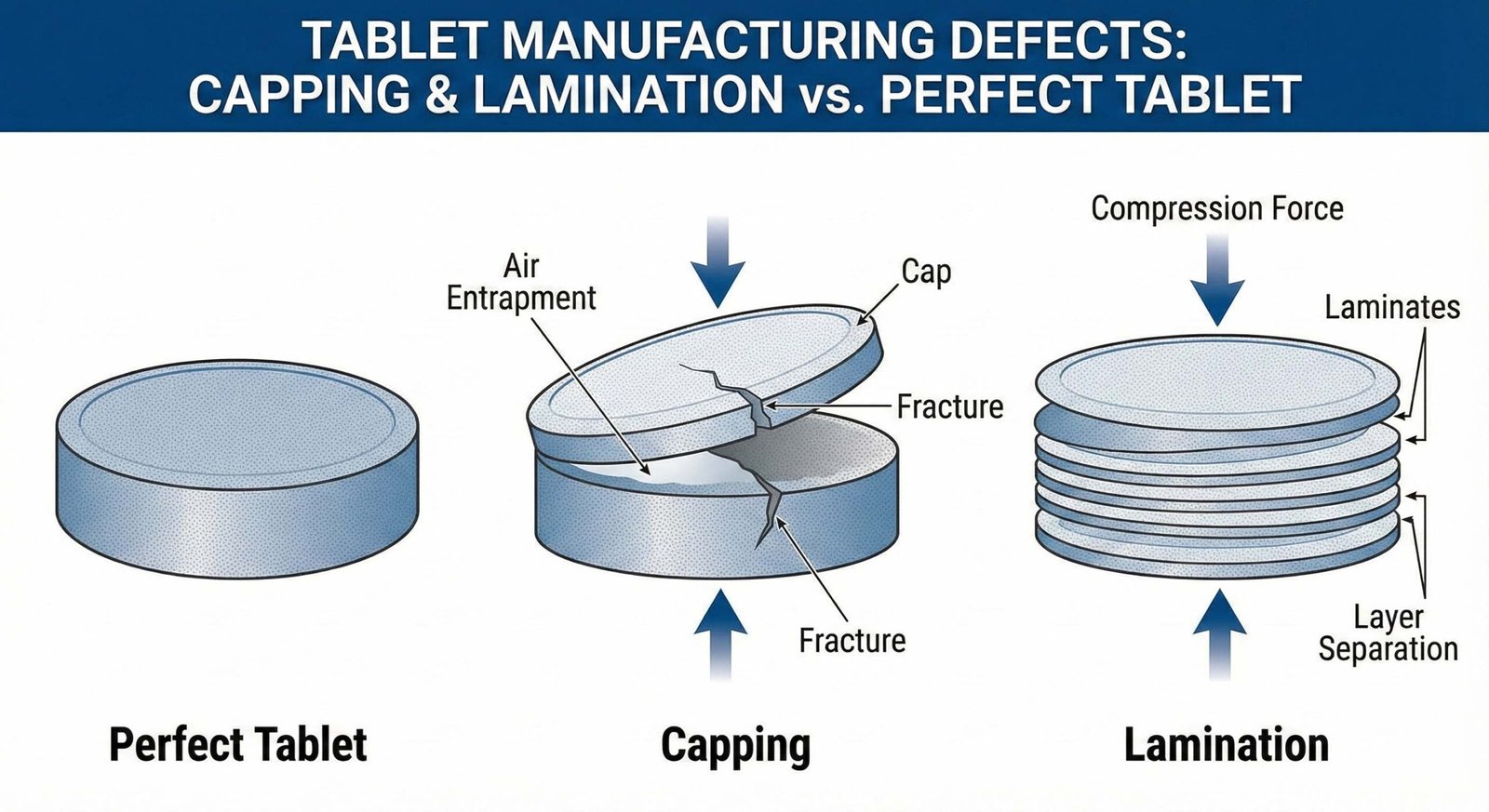

1. Capping and Lamination (The Most Common Headache)

The Problem: The top of the tablet separates (capping) or the tablet splits into layers (lamination) after ejection.

Technical Causes & Solutions:

- Air Entrapment: The powder contains too much air.

- Fix: Slow down the rotary tablet press speed to increase “dwell time” (the time the punch stays under pressure).

- Upgrade: Use a machine with pre-compression stations. Our advanced Hijmachinery models apply light pressure to release air before the main compression, effectively eliminating capping.

- Too Much Fines: The granulation has too much dust.

- Fix: Reduce the percentage of fines in your formula.

2. Sticking and Picking

The Problem: Granules stick to the punch face (sticking) or logos/letters are not imprinted clearly because material is stuck in the embossing (picking).

Technical Causes & Solutions:

- Moisture Content: The granules are too damp.

- Fix: Dry your granules further.

- Punch Condition: The punch faces are scratched or rough.

- Fix: Polishing is key. Regular maintenance of your pill press tooling is mandatory. Chrome-plated punches can also help with sticky formulas.

- Insufficient Lubricant:

- Fix: Adjust your formulation to include more lubricant (like Magnesium Stearate).

3. Weight Variation (Inconsistent Dosage)

The Problem: The tablets vary in weight, which is a major compliance violation in GMP standards.

Technical Causes & Solutions:

- Flow Issues: The powder isn’t flowing into the die consistently.

- Fix: Check your force feeder. If you are using a gravity feeder on an older machine, consider upgrading to a Hijmachinery model with a variable-speed force feeder to ensure uniform die filling.

- Punch Length Difference:

- Fix: Inspect your lower punches. If they are worn unevenly, the fill volume will vary. Precision tooling is non-negotiable.

4. Double Impression

The Problem: The punch twists slightly during compression, creating a blurry or double logo on the tablet.

Technical Causes & Solutions:

- Key Wear: On keyed punches (used for shaped tablets), the key or the keyway in the turret is worn.

- Fix: This is a hardware issue. It indicates that your pill presser machine needs maintenance or turret refurbishment. High-quality machines use hardened steel to prevent this wear.

5. Machine Vibration and Noise

The Problem: The press is shaking excessively or making loud noises, leading to premature wear.

Technical Causes & Solutions:

- Unbalanced Turret:

- Fix: Ensure the turret is properly balanced and lubricated.

- Weak Frame:

- Solution: Many budget machines lack a cast-iron base. Maquinaria Hijm prioritizes heavy-duty casting structures that absorb vibration, allowing for smoother operation at high speeds.

Conclusion: Prevention is Better Than Cure

While knowing how to troubleshoot is a valuable skill, the best strategy is to start with reliable equipment. Many of these defects—especially weight variation and capping—can be drastically reduced by using a modern, high-precision rotary tablet press.

With 20+ years of engineering excellence, Hijmachinery provides equipment designed to minimize common defects through advanced pre-compression systems and precision force feeders.

Stop fighting with your machine and start producing. Check out our latest line of High-Speed Tablet Presses or contact our technical team for support.